Despite the ever-growing variety of breadboxes offered by industry, they still rarely meet the main requirement—keeping bread fresh: inside them it either goes stale quickly or gets moldy. Wooden designs are far more reliable in this regard, and they are easy to make yourself.

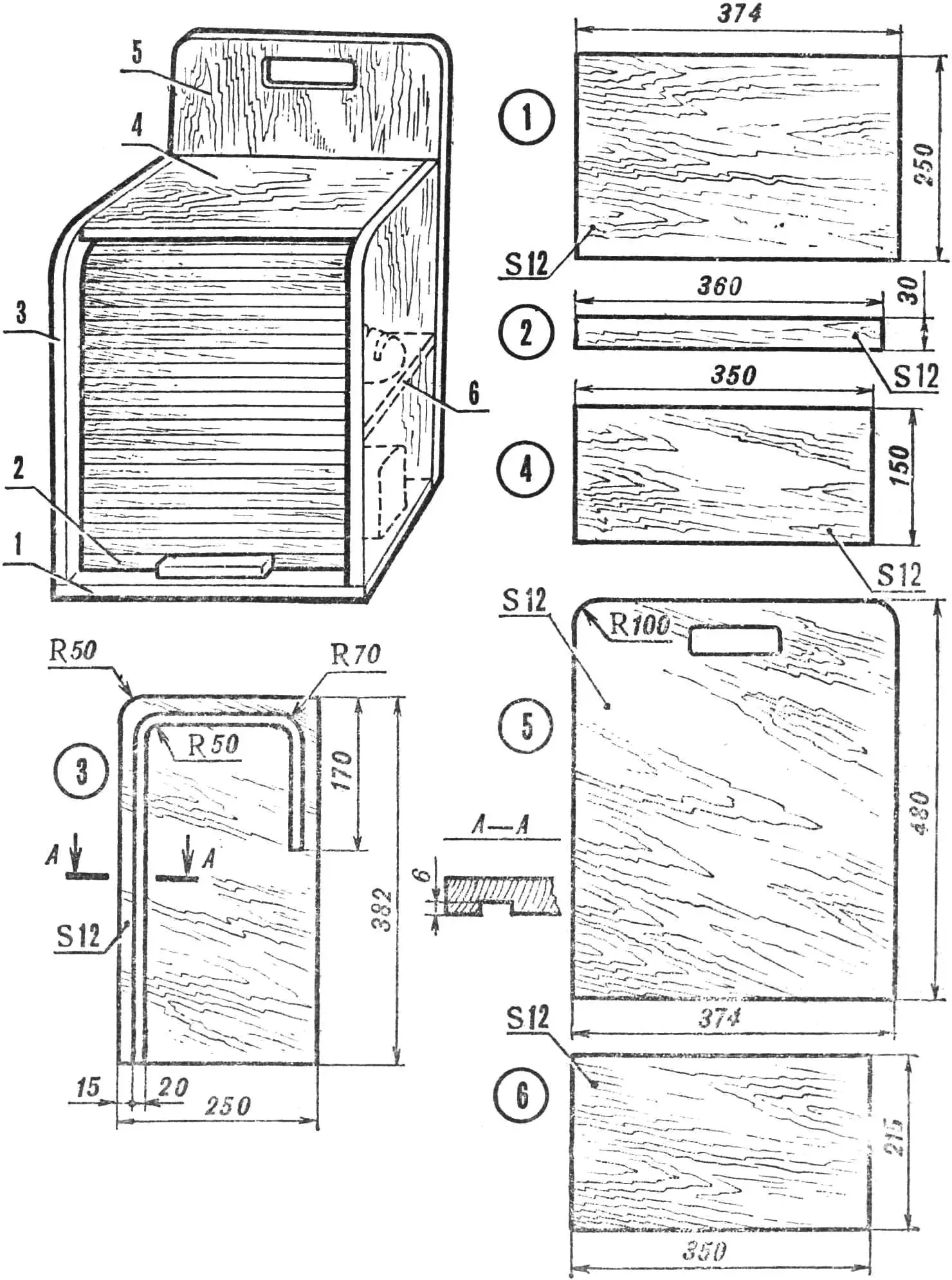

Here is one such breadbox, made from 12 mm plywood. It has two distinctive features: first, it is double-decked—compartments for white and rye bread are placed one above the other. Second, its lid is not rigid, as in most factory models, but flexible, even though it is made from the same plywood.

Now for the construction details. The breadbox consists of a bottom, a middle shelf, two side panels, a top panel, a slatted lid, and a back wall that also serves as a handle for carrying or hanging on the wall. All parts are glued together (epoxy, carpenter’s glue, or PVA), but using loose round dowels is even better: the structure becomes stronger.

1 — bottom, 2 — roll-top lid, 3 — side wall, 4 — top panel, 5 — back wall-handle, 6 — inner shelf.

Before assembly, carefully dress the blank edges with a coarse file and then sand them smooth. It is better not to paint the prepared surfaces; instead, rub them with wax or paraffin and polish with cloth. If desired, decorative patterns or drawings can be added to the visible faces by carving or pyrography. The breadbox will look great if it is coated with a light furniture varnish in several layers.

Finally, a few words about the unusual flexible lid. It is assembled from narrow strips of the same plywood, glued edge-to-edge onto fabric, which becomes the lower (inner) layer after assembly. Grooves for the lid are cut in the side walls with a router or chisel—it is along them that the roll-top lid will slide. A small block glued to the bottom strip works both as a pull handle and as a stop.

The dimensions of the breadbox parts are calculated for a small bread supply for a small family. If necessary, they can be increased—the design allows for it.

B. VLADIMIROV