“Modelist-Konstruktor” awakened in me a thirst for innovation, the desire to do something with their hands. One of his simplest works, I would like to submit to the judgment of the editorial staff and readers of the journal. After reviewing the range of goods in many camera shops, was disappointed, as most frames I’ve seen were either made of plastic or metal, and besides, pretty rough work. I also wanted to have a framework of wood. For large format A3, it is this size and not easy to find, and their cost is prohibitive. In the end, had to either store the images in the album or come up with something yourself.

“Modelist-Konstruktor” awakened in me a thirst for innovation, the desire to do something with their hands. One of his simplest works, I would like to submit to the judgment of the editorial staff and readers of the journal. After reviewing the range of goods in many camera shops, was disappointed, as most frames I’ve seen were either made of plastic or metal, and besides, pretty rough work. I also wanted to have a framework of wood. For large format A3, it is this size and not easy to find, and their cost is prohibitive. In the end, had to either store the images in the album or come up with something yourself.

I decided to independently produce the required framework, starting with the format 10×15 cm

The result was a proposed option, which is easy to repeat even someone completely inexperienced in woodworking. The key thing here is accuracy.

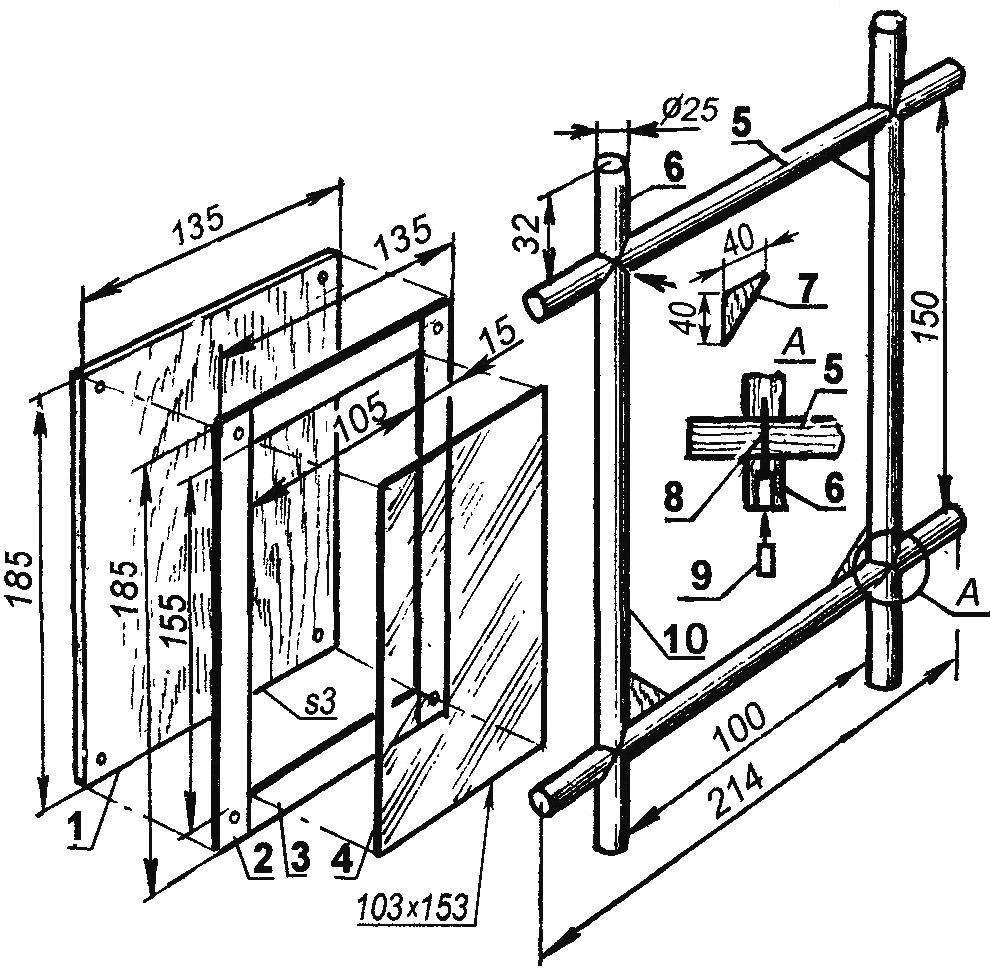

From the materials to the format of the photos or pictures 10×15 cm you will need: wood round rod into blanks of the main frame (length 970-1000 mm; diameter 25 mm); a small sheet of plywood (length 185 mm, width 135 mm; thickness 3 mm); glass (length 153 mm; width 103 mm; thickness 3 mm); four small strips of Plexiglas (two of 185 mm and two 105 mm; width 15 mm; thickness 3 mm); cut plexiglass for the parts (80×40 mm); four screws for wood (4,2×65 mm); four screws for mounting (4,2×19 mm); four wooden dowels; PVA glue; – glue “Moment”.

The first step. Plywood-base pasted with glue “Moment” pre-prepared strips of Plexiglas: lateral (length 185 mm; width 15 mm; thickness 3 mm); top and bottom (length 105 mm; width 15 mm; thickness 3 mm). It should be emphasized that the thickness of the parts made of Plexiglas and screen thickness of glass should be the same. Also need to make sure that between the Plexiglas and glass there was a small gap (1 — 1.5 mm from each edge): it is necessary that the glass is easily inserted and removed. On the plywood at the corners mark the points for drilling on plexiglass and drill through holes for mounting the entire set to the main frame.

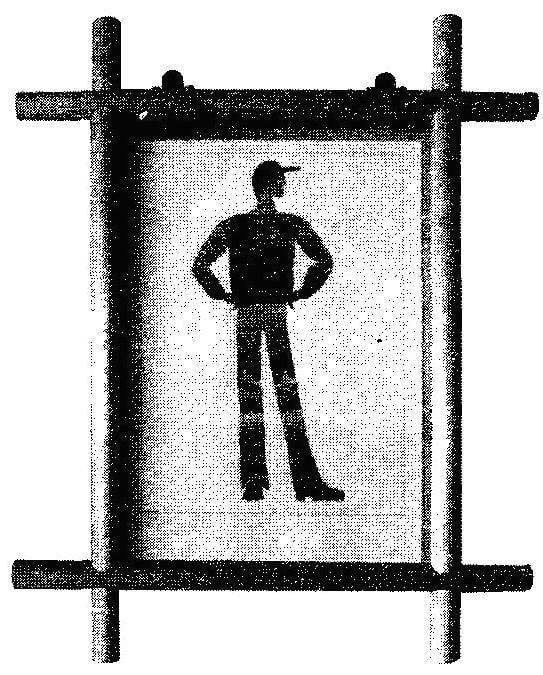

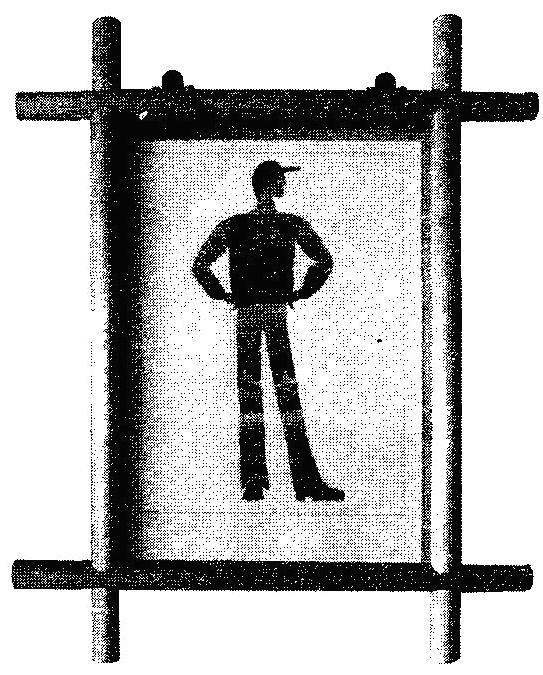

Frame for photographs and drawings:

1—base (plywood sheet); 2—side wall slip frame (plexiglass); 3—slip the crossmember frame (plexiglass); 4—protective shield (glass); 5—cross frame (a wooden rod); 6 extension; 7—area (plexiglass, 4 items); 8—fasteners (screws); 9—the plug(dowel 4pcs.); 10—side panel frame

The second stage. To manufacture the main frame, cut from a wooden rod cylindrical workpiece, two sidewalls with a length of 175 mm each; four short extensions to them with a length of 45 mm and two crossbars with a length of 214 mm.

The third stage—the manufacture of wooden frames. First, in connecting the ends (end faces) of the side walls and extensions to them a round file carefully prepare semi-circular bed that will encircle the rods cross. Then, in the extensions in two passes (first drill a 3 mm, then 5 mm) drilled holes, through which by means of screws and connect all parts of the frame. Holes sealed with wooden plugs-the plugs. Cut from Plexiglas are cut triangles with the help of glue “Moment” are attached to the corners of the frame, as shown in the diagram. They will press to keep the glass.

The final stage— Assembly. On the plywood base to the frame of Plexiglas put a drawing or photo, insert the glass and all placed on a wooden frame. Fasten the whole set with four screws through previously prepared holes in the plywood and the frame from Plexiglas.

The product is ready. Last step—mounting frame to the wall. It may be different from a decorative chain from a variety of hooks.

A. GAMALYA, Saint-Petersburg