A pity to throw away scraps of plywood, thin boards, chipboard, even if there is no place to apply them. However, I have a suggestion: make from scraps of a kind of wood-air oven. This will require glue (PVA or epoxy), sticks, strips, paint (or varnish) and possibly the fabric (e.g. old sheets). Required tools — a hacksaw, or “circular saw” .

So, explain the main idea and the details will depend on your capabilities or intentions.

First of all of the available material is cut into more or less the same tile (say, of size 100×50 mm). If you use trim a different thickness, the workpiece skomplektovat thickness in three groups so that you can put three even layers.

The second phase of training is to build a framework of bars for the size of future boards. Frame yet do not bind, and only lay on a flat surface where you will be working with blanks. Then proceed to build the actual wood of the air plate.

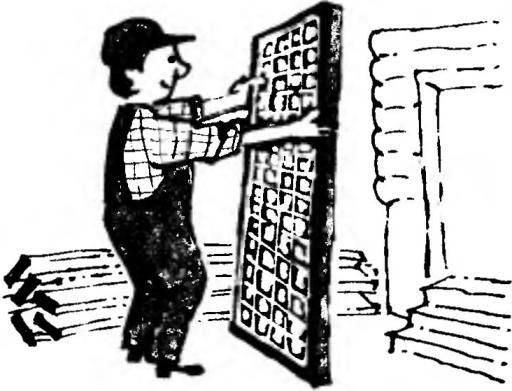

Within the specified framework will lay out the first layer of material in a staggered manner, as shown in the figure. This is the front layer, because regardless of all subsequent actions he must be the most smooth.

The second layer spread on top of the first is also staggered so that the middle of each upper billet were over the joints of the lower corners. Mating surfaces before installation lubricate the glue. If you need, above all, pull something heavy.

If you look carefully to what happened, it is easy to see that the tiles are connected into chains extending parallel to the diagonal of the frame. The task of the third layer to connect the chain, cutting off the remaining Windows, and therefore requires at least three layers of blanks (although, depending on design, can be used and two layers).

So pack smeared with glue billet of the third layer (also staggered) and the result is opaque, but in essence, the lattice (or rather mesh) plate.

Plate of small scraps:

1 — frame; 2 — the first layer of the workpiece; 3 — workpiece of the second layer; 4 — the gaps, close the third layer of the blanks or fabric.

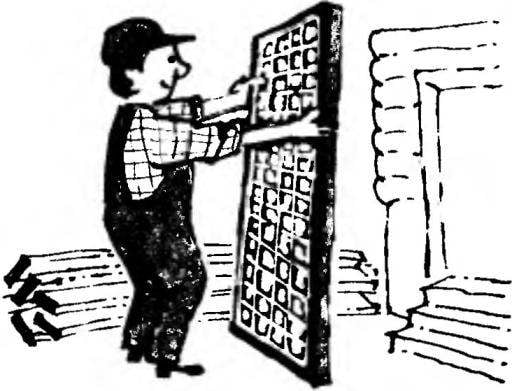

This plate is already possible to use. For example, it can serve as an original grille with the sort of camouflaged holes. Note: if the cooker is assembled from three layers, it is very well painted with a spray gun because, despite the complex form, all the surface available on both sides, and through holes if not.

Of these plates it is possible to make the walls of the barn to dry something, although that probably the technology exists and is easier.

Now, how to make a stove that you can use it as a decorative panel. To do this, lubricate the workpiece surface layer of glue and smoothly, without much pressure put on them piece of fabric. When the glue dries (hardens, polymerizes), proceed to the fun part. Here, the most convenient seems to me epoxy adhesive. Next, you will understand why.

So, soak a cloth in the gaps between the tiles with an epoxy adhesive and put in these wells plastic bags with sand into tissue concavity. After curing of the adhesive packages will be removed without difficulty — epoxy is not grasped with polyethylene. And the impregnated cloth will become rigid and will be the structural material. Therefore, the preferred epoxy adhesive.

At this stage the options. For example, instead of packages, you can stack sheets of polyethylene with sprinkled the top with sand, it is only important that the fabric is evenly and freely exercise, forming a hole. You can opt out of the film and to pour the sand directly onto the fabric: part of it is glued, will be the decorative layer. After painting such a surface also looks interesting.

Now is the time to discuss issues of safety. The resulting plate does not have sufficient stiffness and Flex. To avoid this, contour it with a frame of slats or bars. To strengthen the plate can be glued to the frame of the workpiece and around the perimeter.

Applicable and other methods. Someone will use glue, some screws, and anyone else with something and everyone will be right, because it knows best what he needs. Will tell only that in the large size panels to increase the stiffness and strength good to use a rail or beam in the middle of a plate instead of one row of blanks in the second layer (of course, coordinating their thickness). How will be decorated the edges of the plate and everything else depends on your ability, needs, imagination and ingenuity.

A. POPOV,

Syktivkar,

The Republic Of Komi

Recommend to read CHILDREN WITH “WINDSCREEN” The rain is not afraid of the baby, if you make a "windshield" for his stroller. You will need two separable zippers and a piece of plastic film. Design is clear from the picture. ... UNDERGROUND BOXING When decided to do the car (the material about it were published in the "Modeller-designer" № 5, 2007), then I faced a problem — where to work? Not under the same open sky in the...