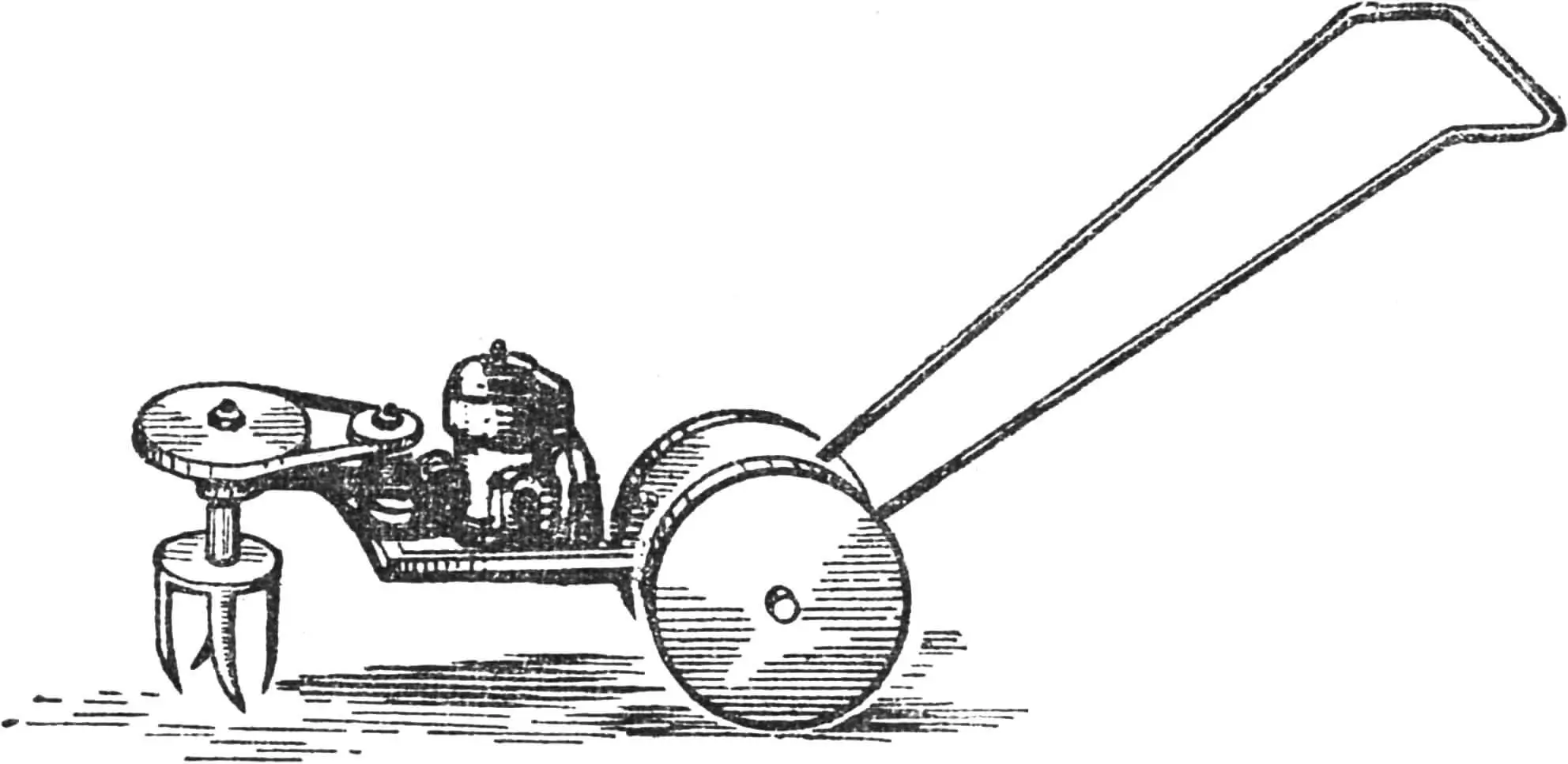

The prototype of the gasoline-powered tiller built by students of the Moscow region school of the “Gorki Leninskie” state farm was based on a machine of the same purpose produced by one of the Latvian factories. It is designed for soil preparation for sowing and planting and for tilling soil in the inter-rows of forest and agricultural crops.

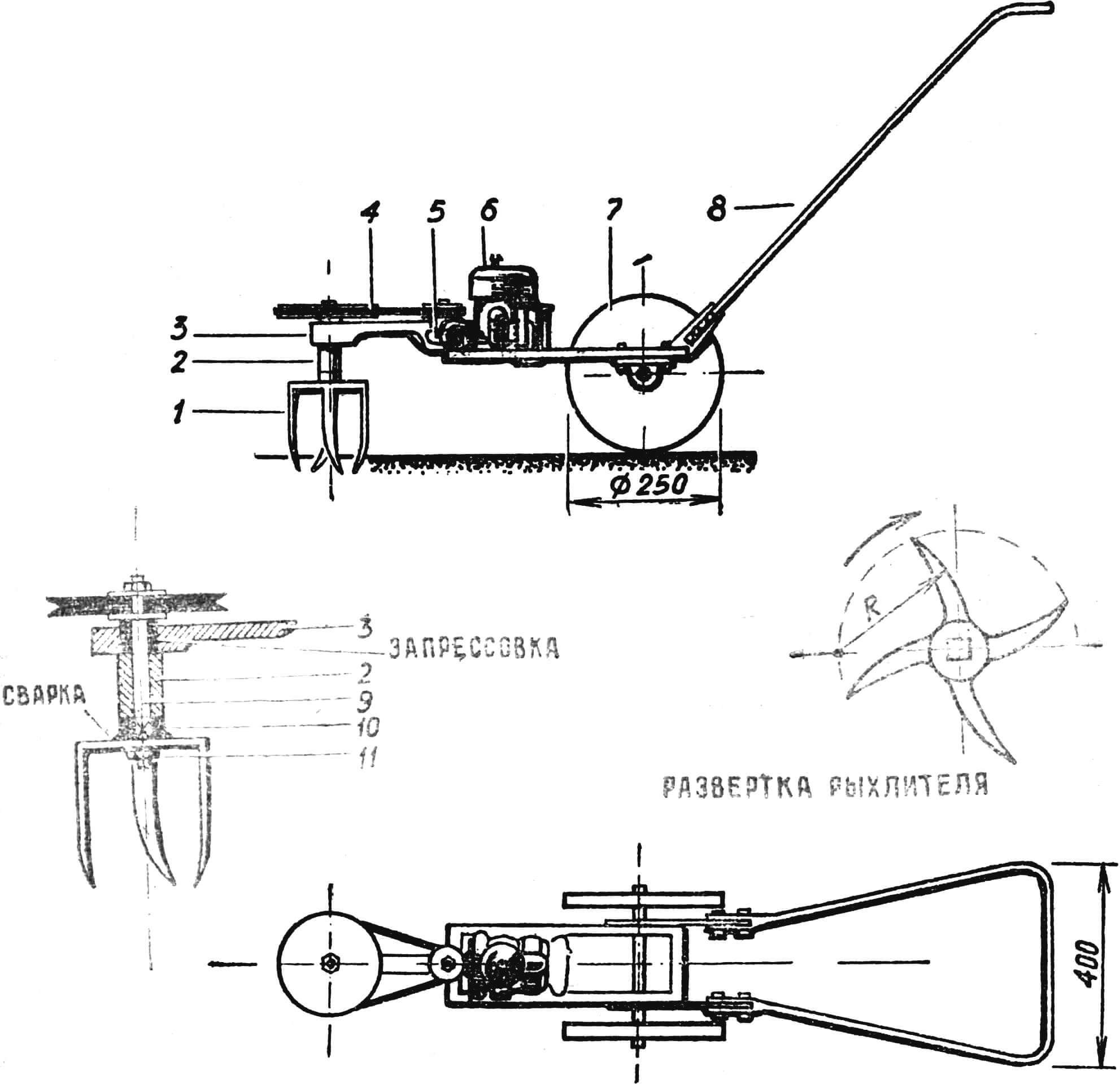

Like the serial one, the tiller created by the guys is equipped with a two-stroke engine from the “Druzhba” chainsaw. Its working organ is four vertical knives that till the soil to a depth of 140—150 mm.

Common to both machines: rational layout of units, V-belt drive, cast drive wheels Ø 250 mm.

But the guys made original knives. In serial machines, they are riveted to a massive base. In the homemade machine, the tiller is entirely made of sheet steel 2.5—3 mm thick. The knives are sharpened on the inside and slightly curved so that the inner diameter of the working organ at the ends of the knives is 100—130 mm.

1 — working organ knives, 2 — pressed bronze bushing, 3 — V-belt drive bracket, 4 — belt, 5 — engine reducer, 6 — engine, 7 — wheel, 8 — tubular control handle, 9 — tiller shaft, 10 — tiller hub, 11 — working organ mounting nut.

The tiller drive shaft Ø 18 mm rotates in a cast iron bushing from the chainsaw, pressed into the bracket. The tiller hub is mounted on the square shank of the drive shaft and clamped with a nut.

For good soil treatment, the rotation speed of the working organ should be no higher than 400 rpm. At the rotation speed of the engine reducer output shaft of 1500 rpm, the belt drive should have a gear ratio:

i = 1500/400 = 3.7.

This means that the diameter of the tiller drive shaft pulley should be 3.7 times larger than the diameter of the reducer output shaft pulley. The tiller rotation speed can be reduced within small limits by changing the engine speed. However, at low speeds, the clutch stops working, since the “Druzhba” has a centrifugal clutch.

The main difference between the machine made by schoolchildren and the serial one is greater work safety. This is ensured by a protective cover. An additional bracket installed at the front allows adjusting the tilling depth. To protect from dust, the pulleys and drive belt are covered with a metal cover.

Now about what else can be improved in the gasoline tiller made by the guys from Gorki. Instead of cast wheels, you can install inflatable ones — they will work better on wet soil. The “Druzhba” engine can be replaced with any motorcycle engine of the same class. Then it’s not difficult to calculate the gear ratio and use a chain drive instead of a V-belt drive. Installing such an engine will also allow varying the rotation speed of the knives within significantly larger limits, and therefore, at low speed, to penetrate them much deeper.

I. KITAYEV, Candidate of Technical Sciences