R and S. 3. Cassette:

1, 4 — rail with holes for cell frames, 2 — adapters for the bees 3 — the Central notches, 5 — d hole 6-7 mm, 6 — bottom and side rake, 7 — wire clip, 8— nut.

Such a hive is especially convenient for out-apiaries on trailers. It is possible and the creation of double, triple and so on variants with common side walls (for stationary pavilions), which gives a significant saving of building materials.

The cassette is a box without a lid and bottom made of plywood with thickness of 4 mm and wooden slats with a cross section 16X16 mm. For walls use plywood with longitudinal outer layers of the wood. First collected frame cassette (preferably spiked), they are glued and nailed first end wall, then the side (nails or 20X1 22X1,5 mm are driven from the plywood with a pitch of 30 mm in the lower and side rails, the top is excluded, as it selects the groove 12X10 mm under the shoulders of the framework).

Fig, 4. Removable table:

1 — area with hard neck, 2, 6 — sides, 3 — area with the locking cutout. 4 — guides for the corners, 5 — cut-out for partition, 7 — pallet table.

The end walls prozvanivatsya two holes of 6-7 mm d to exit, accidentally caught in a closed volume of bees and drones. In addition, the front wall is done with another hole ø 30 mm hole and glued a tapered adapter for bees. Then installed the wire clip. At its ends, are threaded through the side rails, screwed the nuts

After Stripping the cloth blank tapes, double-covered with hot vegetable oil (100 g per cartridge). Plywood, impregnated with oil, almost does not swell from moisture, are covered with propolis and will not stick to the slider. After filling of the cassette framework, it becomes fairly hard.

The removable table is assembled from plates of sheet aluminum of 1 mm thickness and polkas of the same material cross-section 30X30X2 mm, connected by the rivets d 3 mm in 50 mm increments.

Slanted tray table facilitates the rapid transfer of bees from a serviced cassette in the underlying, which reduces the risk of injury when returning the cassette in place.

Fig. 5. Bokova panel of the column (side view):

1 — plywood, 2 — wooden block, 3 — door, 4 — propyl, 5 — skid (area 20X Х20Х1.5 mm). 6 — M5 screws, 7 — Styrofoam.

If placed below other family, in vertical guides of the table you can insert a dural plate-baffle, and the bees that left the extended frame, will gather in the resulting box. Use quick table extremely facilitates the work of the beekeeper, eliminates the need for stands and lifts.

Simplicity of design, availability of materials for production, the ease and convenience of maintenance, light weight retractable tapes compared to the floors Multihull hives gives you the opportunity to bring to the beekeeping students.

G. YAKOVLEV

Recommend to read

“BIRDS” OF THE AMERICAN AND EUROPEAN FLEETS

“BIRDS” OF THE AMERICAN AND EUROPEAN FLEETS

The United States waited almost three years before entered the First world war. And during this time the leadership of the naval Ministry was attentively get accustomed to all the... RIDING ON THE VACUUM CLEANER…

RIDING ON THE VACUUM CLEANER…

Not so easy to store a bulky vacuum cleaner in a small kvartire. Meanwhile, it is quite possible to "hide" so that it did not occupy a special place. For example, it is very convenient...

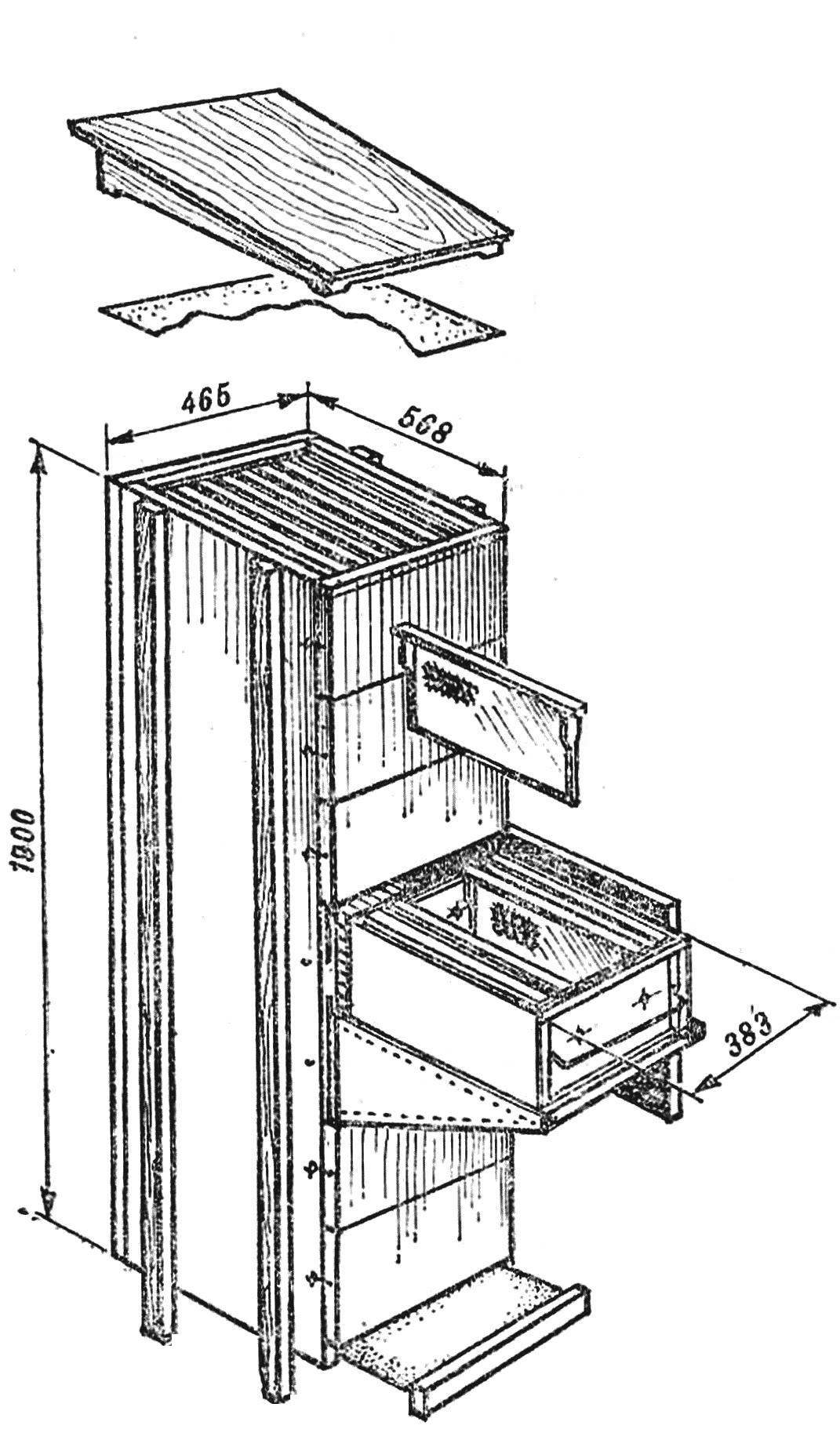

The basis of the hive — a column with tap holes on the front doors on the rear and a slider on the inside of the side walls. On the slider rest seven light plywood cassettes with cellular framework. For inspection and replacement of frames of the cassette may be made removable metal table. Top and bottom of the column access block tick the honeycomb lattice, from the weather hive covers shed roof with ventilation slots.

The basis of the hive — a column with tap holes on the front doors on the rear and a slider on the inside of the side walls. On the slider rest seven light plywood cassettes with cellular framework. For inspection and replacement of frames of the cassette may be made removable metal table. Top and bottom of the column access block tick the honeycomb lattice, from the weather hive covers shed roof with ventilation slots.