The load is attached to one or both arrows at once, depending on its shape and mass as well as height. The heavier the load, the smaller should be the shoulder of application of force and lifting height, otherwise the hydraulics simply can not overcome the force of gravity.

When the cargo is fixed, it can be raised. For this purpose, the lever of the directional valve slowly translate to the position of the LIFT. Linkage rod begin to move up and through the triangle and its tip is exposed to the boom. The cargo off the ground. You can now carefully maneuver.

Being in the right place, we begin to lower. For this purpose, the lever of the directional control valve very slowly move from position fix to position FLOATING. Upon reaching the desired lowering speed, hold the lever until the full load lowering.

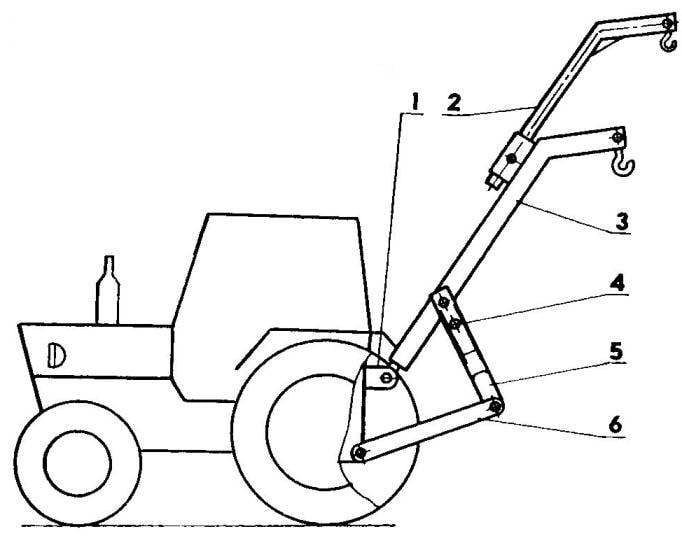

And now a closer look at the device of each of the self-made lift components. For the manufacture of the tip it took a channel 8 and a steel sheet thickness of 5 mm. Of the same materials made by ten parts: two bearings, two jumpers, two eyes and four scarves. The slot in the back of the jumper is a groove for a retainer, which is equipped with “triangle”.

All the parts are connected by welding with double fusion seams. The lugs are drilled through holes with a diameter of 26 mm under the finger mounting end of main boom. Securing the arrow through the upper hole in the tip, you can increase the lifting height, and using the bottom hole is to get to lower lower the boom (this is necessary when some work).

Itself the main boom is made of steel area 90x56x6 mm, to which is welded the entire length of the lateral shelf of the strip thickness 8 mm. Turned steel channel with dimensions 90×64 mm. in addition, under the Central hole is reinforced channel plate sizes 300×64 mm of the same steel strip with a thickness of 8 mm.

One end of the boom is bent at an angle of 40 degrees and is equipped with a mounting hook from the slings of the crane. To the other end with two bolts M 14×1,75 attached to the ball support from the Central thrust, which boom is this thrust is installed in its socket.

On top of the main boom is welded a section of pipe with a diameter of 76 mm. This tube is a guide for a floating boom which allows you to extend the length of the shoulder lift almost a meter.

Additional boom made of thick-walled pipes with a diameter of 60 mm. along the entire length of pipe drilled five holes in order to fix it in the guide with different length extensions. A retainer is a steel finger with a diameter of 14 mm. the end of the extendable boom is also equipped with a mounting hook, but smaller.

That’s all the device. If you have the necessary materials and tools, chief among them — welding machine, the lift can be made in one day. I say this based on our own experience.

Use, despite the simplicity of the design, from the lift a lot. Some only work with it, not had to perform! And oak pillars to the garage to put, and logs to stropit, and a variety of boxes, containers, and even the machines in the vehicle shipping, and on-site work — feeding on the walls of bricks, cinder blocks, beams.

And all this took a matter of minutes, turning from the problem to the interesting case in which get pleasure from the process. And a positive result is guaranteed, as wherever the person is for their needs that fits mechanical AIDS. Especially made with your own hands!

G. LEGOSTAEV, farmer, S. Mishkino, Bashkortostan