For several years I use when hilling and weeding between rows homemade potato field on the tiller. Despite the fact that the coupling weight (therefore, developed thrust) it is clearly smaller than the mini-tractor, motomania satisfied. Although sometimes you have to make an extra effort, pushing the unit forward when working on heavy soils. Overall, a reliable and compact machine. And the ability to quickly translate it into the more compact state (transport and storage) is considered an additional advantage. After all, the real operating conditions of agricultural mini-equipment have is such that it is more idle than working. Winter is long, and garden plots, land plots located far from the garages and warehouses, where this equipment is usually stored.

Tiller is assembled on a welded frame with a motor with air cooling system, muffler, Vozduhoflotsky and starter motor from a chainsaw “Friendship”, fuel tank, intermediate shaft, two-stage chain transmission, drive wheel, bracket for mounted implements.

No problems with storage and transportation, since the tiller folding. We must first remove the upper bolt M10 (see layout of units and parts) and fold control knobs along the top of the rack. Then by unscrewing a couple of screws and remove the corresponding bolt from the bracket main stand with frame, rotate the bracket and tilting the rack forward until it stops in the channel the cross member of the frame, go to the following two elementary operations: detach the mounting bracket attachments (remove the bottom three bolts) and lifting the drive wheel. Releasing the tension, you can remove the chain connecting the drive sprocket with the intermediate shaft two-stage transmission, and then slightly unscrewing the nuts holding the axle of the drive wheel, to release it from the slots. Translation of the cultivator in working condition — in reverse order.

Other features of construction it is necessary to note system of adjusting the chain tension.

Dimensions, mm:

in working condition…………………………..1240x850x900

in the transport position

(removed from the drive wheel and bracket

for mounted implements) …… 780x260x600

Weight (without mounted equipment), kg ……………………25

The operating speed in cultivation, km/h……………………..2

Performance

hoeing between the rows, m2/h.”…… 300

The power unit is a modified D4.

Cooling system — forced with a homemade fan,

Run — the starter from chainsaws “Friendship”.

The transmission is a two-stage chain (і1=4,36; і2=4.8 V).

In the first stage adjustment is performed by moving the intermediate shaft along the guide beam of the frame. You should first loosen the two nuts tightening the clamp securing the intermediate shaft. Then the shaft together with the coupling collar to move along the rail. And after finding the optimal position, to firmly secure. Then pull the second stage chain drive with a special sprocket.

The bearings of the intermediate shaft fixed in the axial direction of the spacer bushings that are installed between the respective hubs of sprockets and bearings.

Sprocket z2=48 taken ready-made from “adult” bike (cut only the levers of the pedals). With the hub it is mounted on the intermediate shaft wedge. Asterisk z3= 10 — vasodilates old modification (subject to prior raskladki welded to the pipe hub and fixed to the axle in the same wedge).

Kinematics of the unicycle metopomancy.

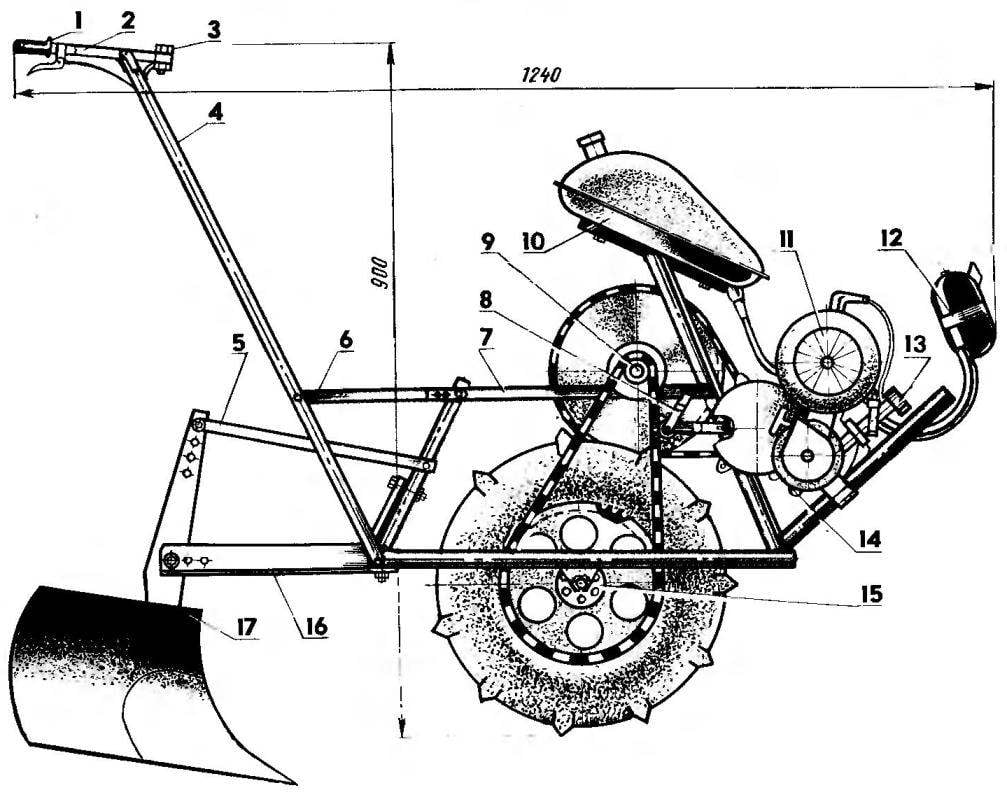

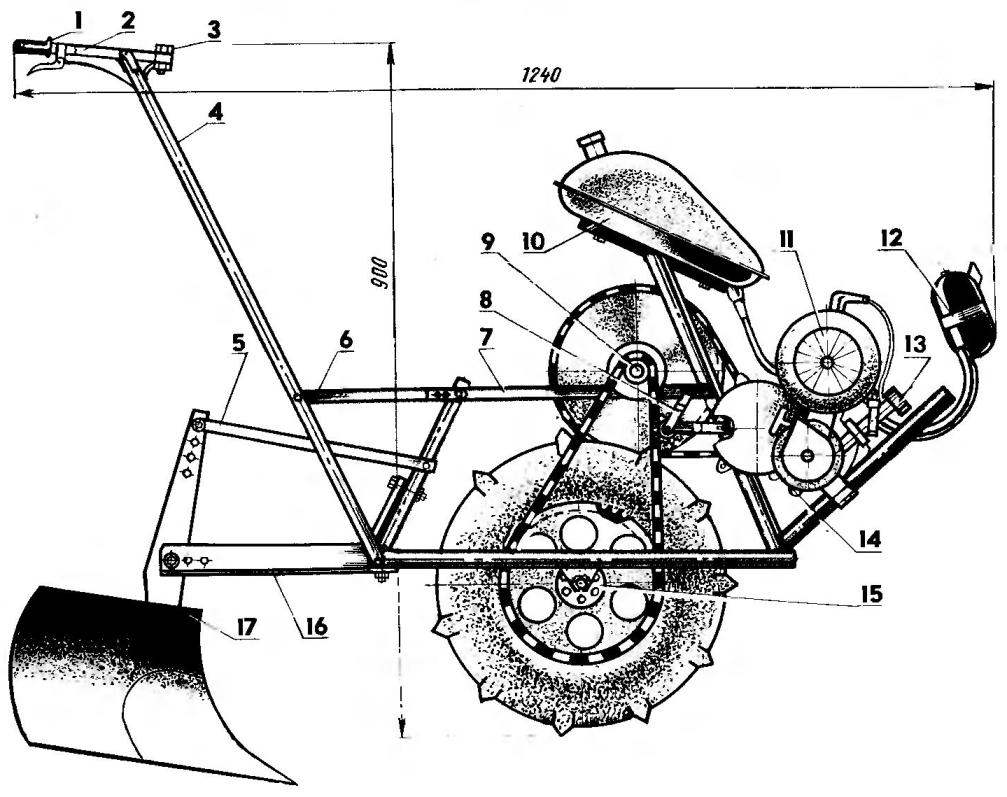

The layout of the pump station (guards removed):

1.2 control arms, 3 — bolt M10 with nut (installed in the working condition of the tiller, 10 pairs), 4 — basic, 5 – rod installation of the mounted equipment (2 EA.), 6 — mounting bracket of the main stand, 7 — frame, 8 — tensioner circuit of the second stage, 9 — intermediate shaft 10 — fuel tank, 11 — fan, 12 — exhaust muffler, 13 — vostokfilm, 14 — D4 engine, 15 — node of the drive wheel, 16 — mounting bracket mounted equipment, 17 — the working body (cultivator or small plow).

Frame:

1 — cross member rear, 2 — bushing (St3, 2), 3 — front rear, 4 — beam of the frame rail (channel 33×23,5×3 bent steel), 5 — prop gas tank, 6 — hour average 7 — hour front 8 — cross member front, 9 — spar, 10 — brackets-axis drive wheel (St3); det. 1, 3, 5, 6, 7, 8 and 9 steel pipe 26,8×2,5.

Intermediate shaft:

1 — wheel hub with pressed on sprocket off the bike, 2—wedge fastener (2 EA.), 3 — the intermediate shaft (steel 45), 4 — case (steel 20), 5 — tie mounts to the frame (steel spring), 6 — ball bearing 80203 (2x), 7 — spacer (steel pipe, L12, 2 PCs.), 8 — wheel hub (steel 45), 9 — sprocket from the engine D6, 10 — beam of the frame.

Front main:

1 – spar (steel tube 21,3×2,5, L690, 2) 2 – retainer side arms (St3 sheet s3, 4 units ), Z – nut M10 4 bracket Central (FCZ sheet s3), 5 – cross member (steel tube 21,3×2,5, L, 200).

Node of the drive wheel:

1 — axis drive wheel (steel 45), 2 – nut M12 (2 PCs), 3 — Grover washer (2 PCs), 4 — bracket left frame spar, 5 — Bush (nylon or Teflon, 2 PCs.), 6 — double hub (steel 45), 7 — bolt M8 (6 PCs.), 8 — drive driving wheel (St3), 9 — grouser (ST5, 11 PCs), 10 — bolt M6 (6 PCs), 11 — sprocket from the bike 12 — longeron right.

The mounting bracket of the main stand (St3, strip 22×3).

The axis of the tensioner chain (steel 45).

Bracket of fastening of attachments:

1 — cross bar (40×40 area), 2, 3 — thrust left and right (area 40×40), 4 — plate (St3, sheet s5).

Control arm left:

1 — the handle (of the motorcycle). 2 — clutch lever with latch (for the right arm — lever throttle control), 3 — rod (rough steel), 4 — tip (St3).

The details of the mechanism chain tension:

a — arm (St3, band 22×4, 2), b — latch (St3, strip 20×1,5, 2 PCs.)

Chains — Cycling, but if possible, better to replace them with more durable. For example, from a moped or motorcycle “Minsk”, “Sunrise” (step these circuits are the same).

Now about the node of the drive wheel. The asterisk z4 =48 bike too. To the outer flange of the hub it is attached by six bolts M6. And to the inner hub flange bolts M8 “tightly” screwed the drive of the drive wheel made of a steel sheet with a thickness of 15 mm.

The leading wheel eleven weld-on grouser, having a “precipitation” profile. They are made of steel plates with thickness 3…5 mm. Height of each — 38 mm, the apex angle of 110°. The ends of the cleats embedded on the 18 mm of the wheel disc and welded thereto. In the hub on both sides of the inserted nylon (PTFE) sleeve, performing the role of bearings.

Fuel tank taken from the old motor bike. It is very convenient because it has a decent volume of 2.5 liters, a good mount and neck with a cover, ensuring the tightness during transport. One filling such a tank with enough fuel to handle the three plots of land 6 acres.

For clutch control used factory handle with lock “squeezed States” are required to start and engine warm-up. “Gas” is regulated by the decompressor lever from an old motorcycle.

As the power plant of the tiller applied motor D4 motor bike. It is finalized, provided with a starting system, and forced air cooling. The essence of revision is that the bolt holding on the crankshaft drive gear (right side engine), installed a pulley of the fan krapovickas for the system launch. Everything about the way in technical solutions, the description of which can be found in the “Modeller-designer” (№ 8’79, 8’84, 2’87, 10’90). Pulley with a rubber belt transmits the rotation of the impeller of an axial fan mounted on the engine head. The gear ratio of this drive i=0,5. The diameter of the impeller is 110 mm, the number of blades is 6. Installed fan on two bearings 200.

The clutch cover is screwed with 2 mm steel plate with centering (relative to the pinion) with a belt, and plate — coil with two mounting flanges. One of them is used for mounting the starter from chainsaws “Friendship”.

In addition, a modified engine replaced clutch lever. It is made of curly, because the drive chain intermediate shaft goes from the motor up, not down, as on mopeds. For the same reason sawed and the upper partition cover covering the driving sprocket. Exhaust pipe shortened and turned 180°.

As Hiller used a hand cultivator (store-bought) with extended sidewalls. On the publication “Model construction” were also made a small plow, but to test its performance while it was not possible. Treated the earth what had already thoroughly used to it. And tried to help his workaholic-tiller to move forward at the maximum depth of the mouldboard. However, the latter is not necessary: you can go and twice at the treated site, but while requiring minimal effort. After all modified and well maintained engine develops quite high torque. And it happened that the wheel will simply slip, without overloading the power unit.

And another tip. When operating the tiller rinse vostokfilm every five hours of work — will not lose.

A. SPEAR,

Bashkortostan

Recommend to read RELIABLE HEAD PROTECTION The human neck is very perfect mechanism that performs many vital functions. However, it is very compact, flexible and surprisingly agile. All this allows to consider it one of the most... VELCRO… THE DOOR Tenacious as burrs, Velcro is not a problem: you can buy new and old things to use. And that's what — and I want to offer: let holds the door open. How? A piece of Velcro stuck to the... Scroll back to top

When creating mechanical prepolitical, tillers and other small tools, the tinkerers are facing a number of problems: from the study of kinematics (reliability, compactness, and originality of technical solutions), acquisition for the planned machines of the nodes of parts (cheap motor, for example) and ending with the Assembly and debugging of the whole structure. How to overcome the most common difficulties and become the owner of a quite workable tiller, is published below material.

When creating mechanical prepolitical, tillers and other small tools, the tinkerers are facing a number of problems: from the study of kinematics (reliability, compactness, and originality of technical solutions), acquisition for the planned machines of the nodes of parts (cheap motor, for example) and ending with the Assembly and debugging of the whole structure. How to overcome the most common difficulties and become the owner of a quite workable tiller, is published below material.