Our reader I. Samotin, a resident of the village volodarskoe the Kokchetav region, “M-K” № 12 in 1983 spoke about how, from readily available materials, to produce mill-kruporushka, so necessary in almost any country house. A simple and reliable device has attracted interest from the readers. Today we offer new development I. Samotin — shredder feed.

Our reader I. Samotin, a resident of the village volodarskoe the Kokchetav region, “M-K” № 12 in 1983 spoke about how, from readily available materials, to produce mill-kruporushka, so necessary in almost any country house. A simple and reliable device has attracted interest from the readers. Today we offer new development I. Samotin — shredder feed.

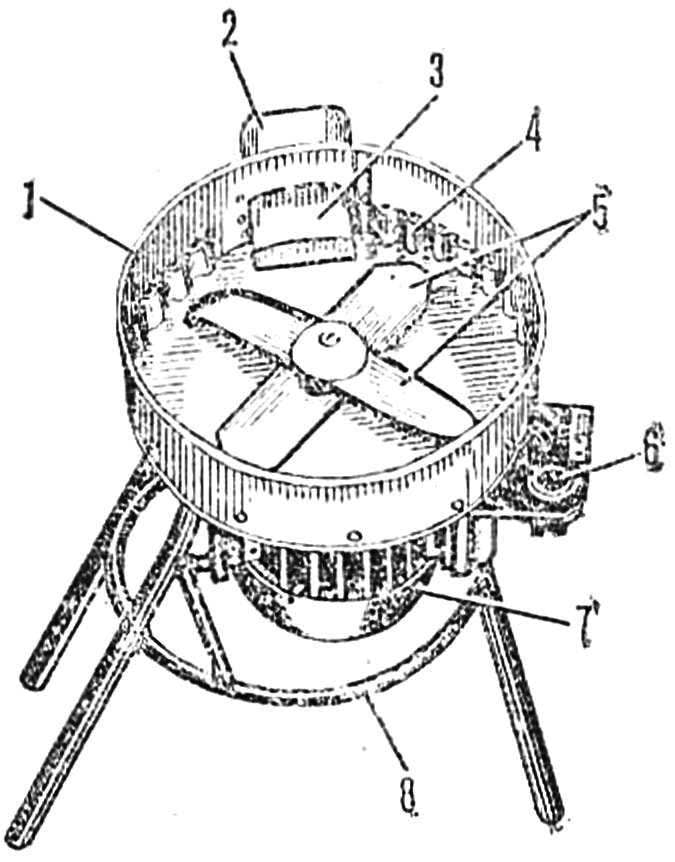

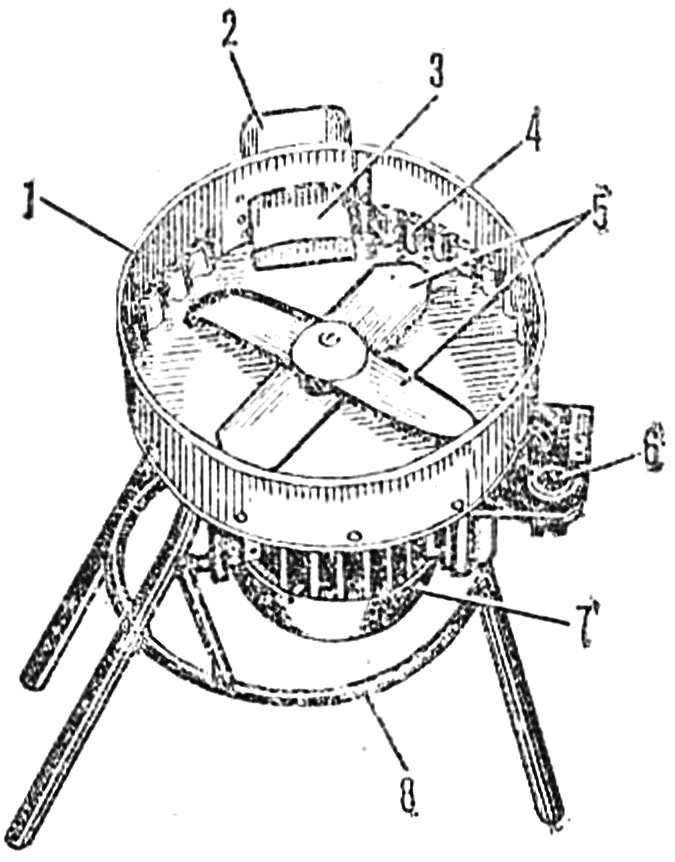

The mechanism is designed for grinding of grass, nettles, burdocks, reeds, corn stalks and cobs, various root crops. The degree of grinding of green mass is governed by its residence time in the hopper. But more on that below; first, what constitutes a chopper.

It consists of a tripod, the motor power of 500 W at 220, a hopper with a lid and a cutting apparatus consisting of two knives — working and “Metallica”.