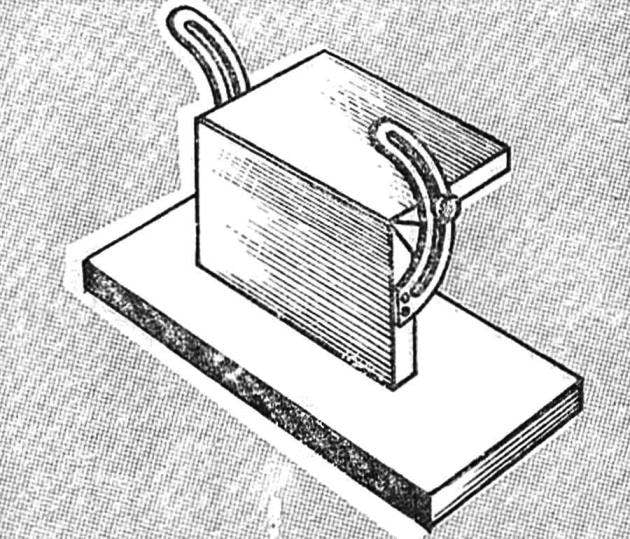

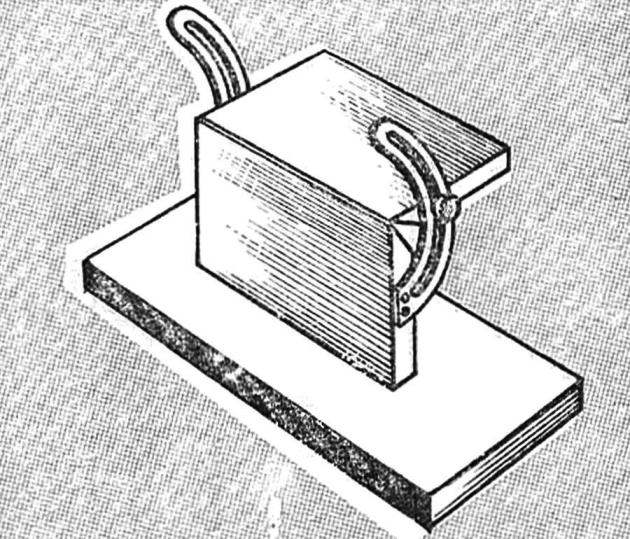

Many questions arise in the manufacture of superstructures of ships models. One of them was how exactly to bend the plastic sheet to the specified angle. Gluing the individual sheets requires Stripping of the obtained joints, and the result is worse than when bending. So we invented a device, which considerably facilitates the bending process. It is used in our group is not the first year and fully justified in the case. It is easy to make from scrap materials, using a pattern; maybe you differently decide the fixation of the movable part at the corner. Recommend about tilting part of the table to place transporters a more precise adjustment of the fixture.

Many questions arise in the manufacture of superstructures of ships models. One of them was how exactly to bend the plastic sheet to the specified angle. Gluing the individual sheets requires Stripping of the obtained joints, and the result is worse than when bending. So we invented a device, which considerably facilitates the bending process. It is used in our group is not the first year and fully justified in the case. It is easy to make from scrap materials, using a pattern; maybe you differently decide the fixation of the movable part at the corner. Recommend about tilting part of the table to place transporters a more precise adjustment of the fixture.

Work with him. Does the billet, which is repeated incision cutter (deepening will allow you to obtain a smooth, neat corner). The workpiece is placed on the table, incision combined with his angle, and the plastic at the bending place warmed up soldering iron. The free end of the workpiece gradually dosimetry to the position of the specified device.

Vladimir GUSAROV, the head of the ship round about, Ulyanovsk