However, the average strip of Russia, not to mention the more Northern regions and Siberia, is a zone of risky agriculture. Here the crop is largely dependent on the vagaries of nature: late spring frosts, early autumn, acid rain or hail in summer. Therefore, rural residents on private land often build greenhouses, and even heated. But these structures are fairly substantial, expensive, and building them with his hands, not all under force.

The owners of the garden six acres usually to protect plants and seedlings do greenhouses pits or boxes that cover the glazed or covered with a transparent film frames.

In thirty years of serious gardening-gardening I built a lot of greenhouses of different designs. Has accumulated in this matter considerable experience, which he shared with lover-mi-gardeners through articles in various publications. Some authors or compilers pointed out my name, others not. But it does not bother me. Importantly, my experience could be used by others.

Flipping through the binder “Modeller-designer”, I noticed that since it has no publications on this topic. Therefore, its development decided to share with readers respected journal.

As the architect designing buildings or a fashion designer designs clothes, so I’m often at leisure, consider and trace the various versions of greenhouses, these structures were not only practical and comfortable, but did not spoil the overall architecture of the site. Often because they have to coexist with decorative pool, openwork gazebo, beautiful flower bed, etc. moreover, good greenhouse itself can become a decoration of the garden plot.

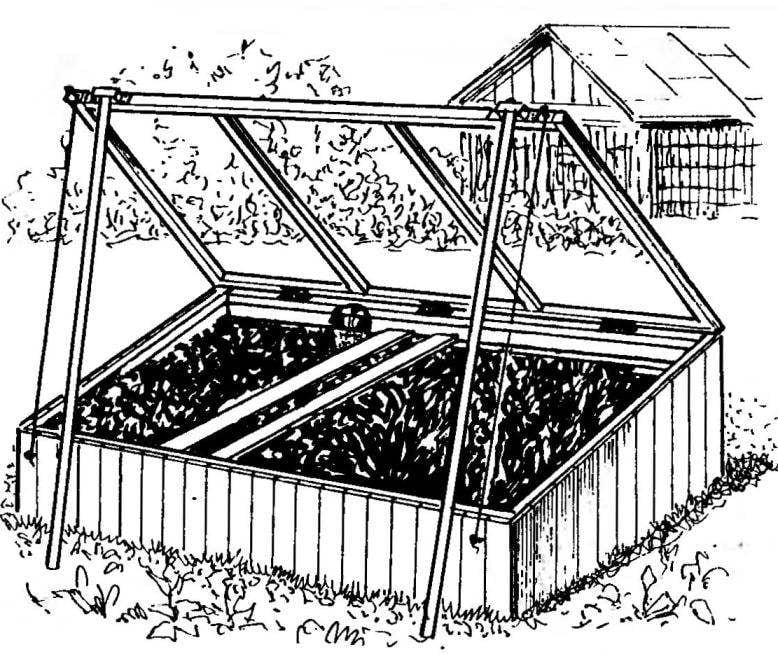

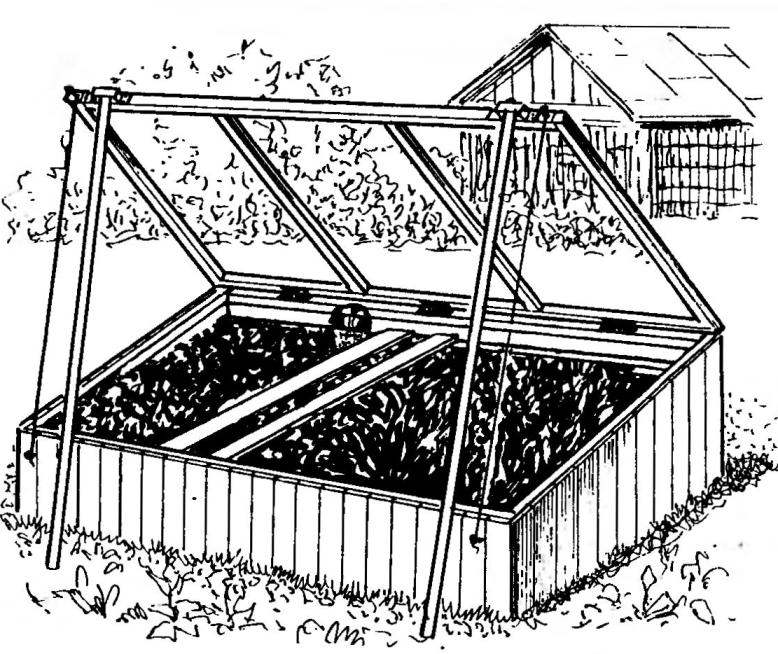

Dual advanced greenhouse with glass walls:

1 — the Foundation-base (cement concrete); 2 — longitudinal wall (2); 3 — safety cord (8 PCs); 4 — supporting pole (rod 040, 8 PC.); 5 — anchor plate (steel sheet s3, 16 items); 6 — staples (wire d5, number of requirements); 7 — podranea beam (2); 8 — column Foundation (cement concrete, 2); 9 — card loop (16 PCs.); 10— technological support (timber 35×35, 4 items); 11 — column (2); 12— bolt (4 PCs); 13 — side wall (2); 14 — opening frame (timber 40×30, 8 PCs); 15 — handle (steel strip 30×3, 8); 16 — technological platforms (boards 200×35); the remaining wood parts are made of 50×50 timber; glass walls; s3; glass frames — s4

Width of conventional greenhouses (like the beds in greenhouses) small and limited treatment capability of the soil and plants in them — as far as can reach the hands. Design my greenhouses are such that this fact does not matter because their width can be quite significant in size in terms of they do not give way to the greenhouses.

So, I want to describe a fairly large and complex (but, in my opinion, most beautiful) of greenhouse developed by me in the course of talking about other, simplified versions.

Under the greenhouse gets a concrete Foundation, or rather the basement, because it only deepens the thickness of plant (humus) layer to subsurface soil. Well as inert material (filler) to use expanded clay or slag — wall thickness of the cap is small, only 80-100 mm, but then it will provide the necessary thermal protection in frosts on the soil. The base can be folded from butovogo a stone or half a brick, using only the red (burnt). If the greenhouse is not stationary and in the future it is planned to move to another place, under the walls of the greenhouse (panels and frames) it is expedient to lay sleepers — bars or framed at least the top is not thick logs. The width of the edging must not be less than the wall thickness. Yourself ingredients, it is desirable to impregnate with preservative.

After pouring concrete in collapsible formwork must be gun it at the top of the base plate or anchor bolts for subsequent attachment to them of the walls of the greenhouse. If the cap stone or brick, it is necessary to lay wooden antiseptirovannye stoppers, to which (and the sills) using a carpenter’s clamps can be fastened to the wall of the greenhouse. Staples are easy to made and most of the thick wire. Concrete pedestals when casting reinforced with steel profiles, pipes or thick wire.

Advanced greenhouse with double walls:

1— the Foundation-base (ceramic bricks); 2— siding (Board s15); 3— mounting clamp (wire d5, 8 items); 4 — antiseptic tube (250x125x65, 8 pieces); 5 — rail frame high longitudinal wall (timber 35×35,2); 6 — inner lining (plaque s15); 7 — rail frame side walls (timber 35×35,4 items); 8 — opening frame (timber 40×30, glass s4, 4 PCs.); 9 — supporting pole (wooden rod d40,4 PCs); 10 — safety cord; 11 — handle frame (steel strip 30×3,x4); 12 — technological support (timber 35×35,2); 13 — technological platform (Board 200×35); 14 — podranea beam (timber 50×50); 15 — base column (ceramic bricks); 16 — front support beam (timber 50×50); 17 — crossbar widening (timber 35×35,4 pieces); 18 — front of the frame longitudinal walls; 19 — rack frame side walls

A simple greenhouse:

1 — tying the longitudinal walls (timber 35×35,4 pieces); 2 — technological support and stand (timber 35×35); 3 — lining of walls (tongue-and-groove Board paneling s 15); 4 — safety cord; 5 — foot pole (wooden rod d40,4 PCs); 6 — rubble plinth; 7 — technological platform (Board 200×35); 8— rail side walls; 9— retaining clip (wire d5,8pcs.); 10— wooden antiseptized tube (8 PCs); 11 — high stand (timber 35×35,2); 12 — card loop (8 PCs); 13 — opening frame (timber 40×30, glass s4, 4 items); 14 — handle (steel strip 30×3,x4); 15 — low front (timber 35×35,4 PCs.)

The walls of the described greenhouse — glazed framework, although one that is on the North side, you can make the deaf. Frame — with upper and lower studs and posts from boards section not less than 50×50 mm.

Other wall greenhouses can be done in the form of a box of planks in one or two layers. When you double-layer the walls of the outer boards should be nailed vertically and the inside horizontally. In this case, the bars of the frame can take and thinner — 35×35 mm.

When the device-layer wall Board (tongue-and-groove or quarters to avoid cracks) are nailed on the outside. Before installing the box base, it is desirable to seal to put on it strips of moisture-proof material (roofing, roofing material or plastic film). To increase the service life of the wall from the inside can be sheathed with galvanized tin.

The connection of the walls of the greenhouse in the corners — carpentry clamps or suitable long bolts with extended washers.

The longitudinal walls of rectangular form, side — truss with vertical rods of the uprights. The farm is shaped like a trapezoid with a short upper base and sloping sides.

Form the side walls of the other options depends on the design of the greenhouse. If the greenhouse shed, they form a quadrangle with a sloping top side. In extended or double structures with a rectangular or isosceles trapezoid respectively.

Side walls and two way extended top greenhouses are additionally associated to the longitudinal under-frame beams with transverse crossbars. All of these items can be made from the same timber as the piping walls.

So the beam does not bend under them (or under girders) having an intermediate stands of timber 50×50 mm or steel pipe of suitable diameter, which rely on a small pier Foundation or to take timber beams thicker — 120×120 mm.

The coating of the greenhouse — from the set of frames. At small length scat unilateral greenhouse, you can close one single-piece frame, with a significant several. Factory frame greenhouses, made of timber section 50×40 mm, are usually superficial dimensions are 1600×1060 mm. Focusing on these dimensions or by choosing your frame you can make yourself. Glazing bars in the frames do not have to cut the seam— proofs can be secured upon the bars of covers not thick (7-8 mm) strap-beadings a width slightly greater than 1/3 of the thickness of the bar on both sides of the glass. Large openings in the frames should not be done, then it will be possible to use even a small galley glass, and in the case of wrapping the frames with film it is not much SAG. In the latter case the coating is better to make an arched roof, then rain water will not accumulate in the lattice frame. If the frames are large gaps, they need to close the cover strips.

The wooden parts of the greenhouse, it is desirable to cover it with outdoor paint that color, not to spoil the architectural ensemble of the site. If the harmony of the buildings “no headache”, it can be impregnated with lubricating oil, even waste, and dry.

Greenhouse lightweight construction:

1—groundsel (banded antiseptized timber d120, 4x); a 2.8 — tying of the walls (timber 35×35,8 PCs.); 3,6 — paneling wall (tongue-and-groove Board paneling s15); 4 — safety cord; 5 — foot pole (wooden rod d40, 2); 7 — technological platform (Board 200×35); 9 — bracket (wire d5, quantity— as required); 10 — card hinge (3 PCs); 11 — rail frame (timber 40×30-4 pieces); 12 — the frame (wire d5); 13 — cover frame (plastic film); 14 — clamping the bead (the rail 20×10, 4 pieces); 15 — handle (steel strip 30×3, 2 PCs.)

The glazing of the sashes without the quarters (bead both sides of glass):

1 — bar cover; 2 — beadings; 3 — crystal; 4 — nails

Positioning the greenhouse, of course, better on the South side of the house, and the unilateral and expanded greenhouses — slope to the South, two — way- slopes to the East and the West.

Another feature of the rational constructive — technological Board-a platform for plant care in the greenhouse. Board (not less than “thirty”) are placed on cranial bars are attached at one height to the longitudinal sides of the walls of the greenhouses. Work on these boards can be sitting and even lying down.

Large greenhouses can be separate vertical frames, upholstered in films, and simultaneously grow a different culture.

In warm weather, the greenhouses open. For this back bruski obvjazki frames are attached to the upper longitudinal beam articulated on two hinges each card. Front under frame fills the staves-stops with a couple of clips-limiters on the top end. To the frame is not knocked over by the wind, they contact the wall of the greenhouse stretched cord.

To increase the life of the greenhouses in the winter it is desirable to disassemble and store in the shelter under the canopy. If this is not possible, then at least close, for example, sheet iron.

And the last heating, more heating. Usually in greenhouses it is not provided, but it can be done the same as in the greenhouse (perhaps except the furnace). Most efficient heating for greenhouses — biomass or solar.

A. KOLOMEYTSEV, Chelyabinsk -70

Recommend to read MACHINE MARSHALL Parades of old cars occupies pride of place of the car GAZ-61-73. This battered machine, with the body of all the memorable "emka", only some kind of leggy like prepodavala on tiptoe (a... AEROPUER Today we'll explain how on the basis of a moped or scooter (or rather, their main nodes) to make not too difficult aeropuer - a vehicle driven by a propeller. He walks well on ice and...

Scroll back to top

In our difficult time many people previously not even tempted to work on the land, got the land and grow vegetables-berries, which become a significant food primacom to the table in General and vitamins in particular.

In our difficult time many people previously not even tempted to work on the land, got the land and grow vegetables-berries, which become a significant food primacom to the table in General and vitamins in particular.