The Colorado potato beetle I encountered in the summer of 1992, when I first planted potato field with an area of just one hectare. At the very least, but some days I hand sprayer this hectare treated. But the discomfort from this work still remember.

Had to suffer in the next two years. But when I decided that landing it is necessary to expand to two hectares, we first thought about the need to mechanize the spraying of potatoes. Manual labor is not only an unnecessary loss of time and effort, but also, more importantly, health hazards. You have to contact with poison and, not oberhause, the danger of poisoning exists, and is quite serious.

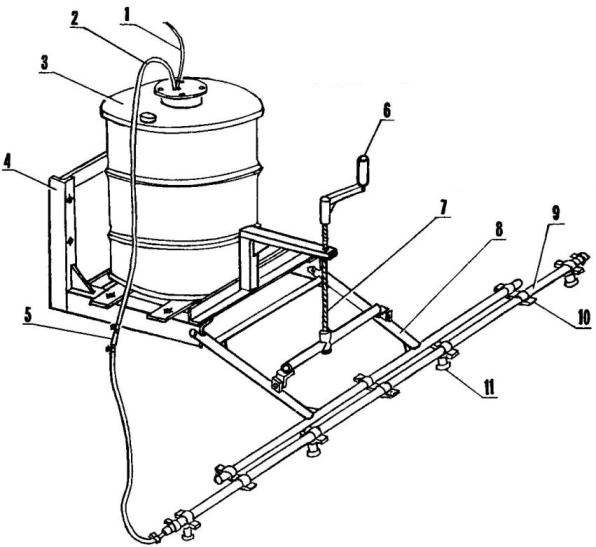

Sprayer for mechanical handling of potatoes:

1 — electric cable; 2 — supply hose; 3 — reservoir; 4 — frame; 5 — connecting fitting (stainless steel pipe 12×2, L80); 6 — handle of the lifting mechanism; 7— the screw of the elevating mechanism; 8— hinge frame; 9 — pressure rod; 10 — clamp; 11 — body spray (sprayer OPSH-15,4 PCs.)

Frame:

1,5 — crossmember (steel, strip 50×10); 2 — bracket (area 90×56, 2); 3—rail (area 50×50); 4— front (tube 50×50); 6 — tool tray (the area 90×56, 2); 7— boom (tube 50×25); 8 — solitaire (steel, sheet s6, 3 PCs.)

Upon reflection, I decided to make a sprayer for mechanical handling of potatoes is not very difficult. Only need a few factory nodes — spray Assembly buildings. The rest of it is easy to make yourself.

Dispensers I quickly found in one collective farm and immediately began to work.

Just bring the list of required materials and components required in the manufacture of the sprayer. It is a metal barrel with a capacity of 200 l; steel angles sections 90×58 and 50×50 mm; steel pipe round section (diameter 32 mm), as well as square and rectangular cross section (respectively 50×50 and 50×25 mm); pipe made from rigid PVC (32 mm diameter) and the hose of soft polyvinyl chloride (diameter 16 mm); electric pump for a working voltage of 12 V; lead screw 14×3 Tg LH length of 400 mm.

Of equipment needed welder, electric drill and the usual set of manual Handtools.

It took to carve on a lathe two adapters to connect pump with the hose and hose the hinged rod cap on the rod and fitting.

Sprayer design is very simple. It consists of a powerful frame, which four bolts fastened to a homemade front hitch of the tractor MTZ-80; articulated frame, pressure rods with four nozzles and the tank with the solution.

In the vessel 50 mm from the bottom, dangling the pump from the car electramone NTS-300 12 V. the pump capacity is enough to operate the sprayer.

Turn on sprayer from the tractor cab conventional switch which directly closes the positive wire of the electric cable going to the pump. Solution from the pump the hose goes to the discharge rod and through the spray falls onto the surface.

Linkage:

1 — axis handle (steel, rod d10) 2 — handle (tube 14x 1,5); 3 — the lever (pipe 12×12); 4 — gusset plate (steel, sheet s6); 5 — screw 14×3 Tg LH; 6 — boom frame; 7 — mortgage nut; 8,10 — thrust washer; 9 — thrust bearing; 11 — shoulder (tube 32×3, 2); 12 — bracket (area 50×50, 2 PCs.)

Hinged frame:

1,4 — lugs (steel, sheet s8); 2 — cross (pipe 25×2); 3 — longitudinal traction (tube 32×3,2); 5 — cross member (tube 32×3); 6 — solitaire (steel, sheet s3, 4 PCs.)

Pressure rod:

1 — the supply hose (soft PVC, pipe 16×2); 2,5,9 — pinch clamps (steel, strip 14×2); 3 — bolt M6 (3 pieces); 4 — adapter (stainless steel); 6— rod (solid PVC pipe 32×2); 7 — clamp (steel, strip 20×2, 3). 8 — M8 screws (9 PCs); 10 — the plug (D16T)

Pressure rod with sprayers attached to the swivel frame, therefore, it is movable relative to the frame of the sprayer, that is, its height can be changed. There is a lifting mechanism to adjust the distance from the rod to the ground depending on the height of plants, depth of furrows in the soil, the direction and force of the wind.

Now, more focus on the design of the sprayer and the manufacture of each of its node.

The frame is welded from pieces of steel profiles of various sections: angles 90×56 and 50×50 mm, square and rectangular pipes 50×50 and 50×25 mm, strips 50×10 mm and rails with a thickness of 8 mm.

In the brackets of the frame drilled four holes with a diameter of 12.5 mm for M12 bolt mounting the sprayer to a homemade front hitch of the tractor. The hole in the cradle frame is designed for four bolts of the same size, the fixing tank solution.

The lifting mechanism consists of a leadscrew with left-hand trapezoidal thread 14×3 Tg LH (can use the screw from the “Zhiguli” of the Jack), duplica handles and lifting straps. Strap made from resistant sleeve, two shoulder — pieces of the pipe 32×3 mm and two brackets — segments area of 50×50 mm.

Structurally, the frame of the sprayer is inseparably connected with the lifting mechanism, since before his Assembly screw first, was is screwed into the nut embedded in the end hole of the boom frame, and then at the end of the screw welded to the first thrust washer, then put duplica lifting strap and welded the second thrust washer.

The hinge frame is also assembled with the use of electric welding of the pipe sections with diameters of 32 and 25 mm, ears and head scarves made of sheet steel with a thickness of respectively 8 and 3 mm. To the frame of the sprayer frame attached, of course, the hinge by two bolts M12.

Rotating the screw knob, it is possible to increase or decrease the lifting height of the pressure rod relative to the surface of the earth.

The pressure rod is a plastic tube with a diameter of 32 mm, which is three clamps secured to the swivel traverse frame. The left (in the direction of the tractor) rod end closed dural plug, and the right one is through the adapter connected to the supply hose. The clamps on the rod ends are used to seal joints and do not allow the solution to leak out.

At the bottom of the rod at a distance of 700 mm from each other drilled four holes with a diameter of 13 mm under body spray. Of the body with the spray taken from industrial brand sprayer OPSH-15.

The last unit of construction — the tank is made of 200-litre barrels with thick walls. Thick walls are necessary because in the manufacture of the tank used welding tanks.

At the top of the barrel — Luc, and the bottom two plate supports for installation on the frame of the sprayer. Through the hatch into the tank entered the pump and hung there on a thin rope (from the clutch of the motorcycle) to the welded bracket.

The hatch is closed, in which slotted hole for the outlet of the feed hose and electrical cable of the pump. Cover with four bolts M8 is pressed against the flange welded to the top of the hatch.

For the manufacture of the sprayer took me only a few days. Then — test. Poured into a container of water and turned on the pump. The first thing I saw from the tractor cab, like a rainbow played all its flowers on the thinnest film fan spray pattern. Clicked the switch, and rainbow went out. The body spray is designed so that upon termination of the fluid pressure of a special collar under the force of the compression springs block access of the liquid to the atomizers. So outside the worker process on the ground not get a single drop of solution.

The sprayer captures four rows of potatoes at the width row spacing of 70 cm I hung it, as already mentioned, on a homemade front hitch of the tractor. Rear agregating tractor with cultivator-Hiller. Thus, it is possible to simultaneously perform two operations — spraying and inter-row cultivation. It is convenient: it saves time and fuel, and less compacted soil wheels. Two operations in one pass— it is already advanced word in agriculture. Where agricultural production is paid much attention, like no surprise. It is still a novelty.

By the way, the sprayer can be used not only in the fight against the Colorado potato beetle. Growers know how important for the development of root crop fertilizer. One of the strongest effects in the cultivation of potatoes foliar feeding plants when during the formation of tubers on potato leaves sprayed small doses of saturated water solution of mineral fertilizers.

Reservoir solution:

1 — electric cable; 2 — inlet hose (soft PVC, pipe 16×2): 3 — filler cap; 4 — a tank (metal barrel with a capacity of 200 l); 5—electric pump (NC-300,12); 6,8 — supports (steel, strip 80×10); 7— adapter (stainless steel); 9 — manhole cover (steel, sheet s3); 10 — flange (steel, лнств4); 11—a bolt M8 (4 PCs); 12 — Luc (steel, sheet s4); 13 — loop suspension pump (steel, rod d6); 14—cable d2

To talk about what biochemical processes occur at this time as a result of this procedure in the plant for too long. I will say briefly: very useful for fertilizing crops. But again — without a special machine, this technological process is impossible, and a homemade sprayer easily cope with this work. So it works on the crop from two directions!

I would like to mention another one here. The solution in the tank must be thoroughly mixed. How to achieve this? You can, of course, the filler neck properly enter and search for some kind of long stick. But I do it differently. Cut the supply hose in the middle and put into the slit of the connecting fitting.

Now, the Gulf of the solution into the reservoir and pre-stirred it with a clean stick, I disconnect the upper hose from the barb, is lowered into the barrel and includes a pump. A few minutes is enough that the spray from the hose to thoroughly mix the solution until homogeneous. Then put the hose onto the fitting and tighten the clamp. Okay, we can start work.

The performance of my sprayer (in the presence of water at the edge of the field) — up to one hectare per hour. The quality of the spray pattern and uniformity of coverage is very high. Blemishes, rough places are left.

…Always nice to see the results of their labor. And when at sunset standing on the edge of the field, admiring the neat rows of flowering potatoes, remember, as plowed in the spring, as planting the tubers in black, without a single blade of grass soil, and then day by day watched how timidly at first hatch from the earth, the first shoots, then all the stronger is the growth of the potato Bush, and you realize that everything is brought to life by your efforts, your hands, so then there remains in the soul no room to doubt the correctness of the chosen path, no worries — nothing that could shake faith in yourself, in your strength.

Free labor on their own land — what more could a man with peasant roots? Moreover, today it is possible to make it more creative and less heavy to mechanize a labor intensive operation. Each homemade machine — one more step, one more small victory, one more success in life.

G. LEGOSTAEV, farmer, Bashkortostan

Recommend to read REZINOMOTORNAYA PARITEL’ Recently we met with a model glider class Ä1. In the design of its supporting planes, and stabilizer are widely used Styrofoam, which greatly simplifies the manufacturing technology was... STEERING THE MACHINE WITH THE MEMORY BLOCK It differs from steering devices based on electromagnets less weight, reliable fixation of steering, more traction and efficiency. The memory block machine provides a return of the...

A real scourge of the potato fields was the Colorado potato beetle. And in recent years because of the warm winter it is getting more and more. To deal with it in different ways. But the most reliable and effective way all the same- spraying with special chemicals. If the area is small, then no problem. Buy in store or on the market hand-held sprayer for any model that is charged with a solution of capacity for work! An hour and a half and the plot of the pests exterminated. But this, again, in that case, if the potato plantation is small – five to ten acres.

A real scourge of the potato fields was the Colorado potato beetle. And in recent years because of the warm winter it is getting more and more. To deal with it in different ways. But the most reliable and effective way all the same- spraying with special chemicals. If the area is small, then no problem. Buy in store or on the market hand-held sprayer for any model that is charged with a solution of capacity for work! An hour and a half and the plot of the pests exterminated. But this, again, in that case, if the potato plantation is small – five to ten acres.