Preparation of feed for Pets will go much faster with electrothermy. Five minutes turns out two buckets of chopped vegetable mass — juicy supplements to straw, the Seine and other dry food.

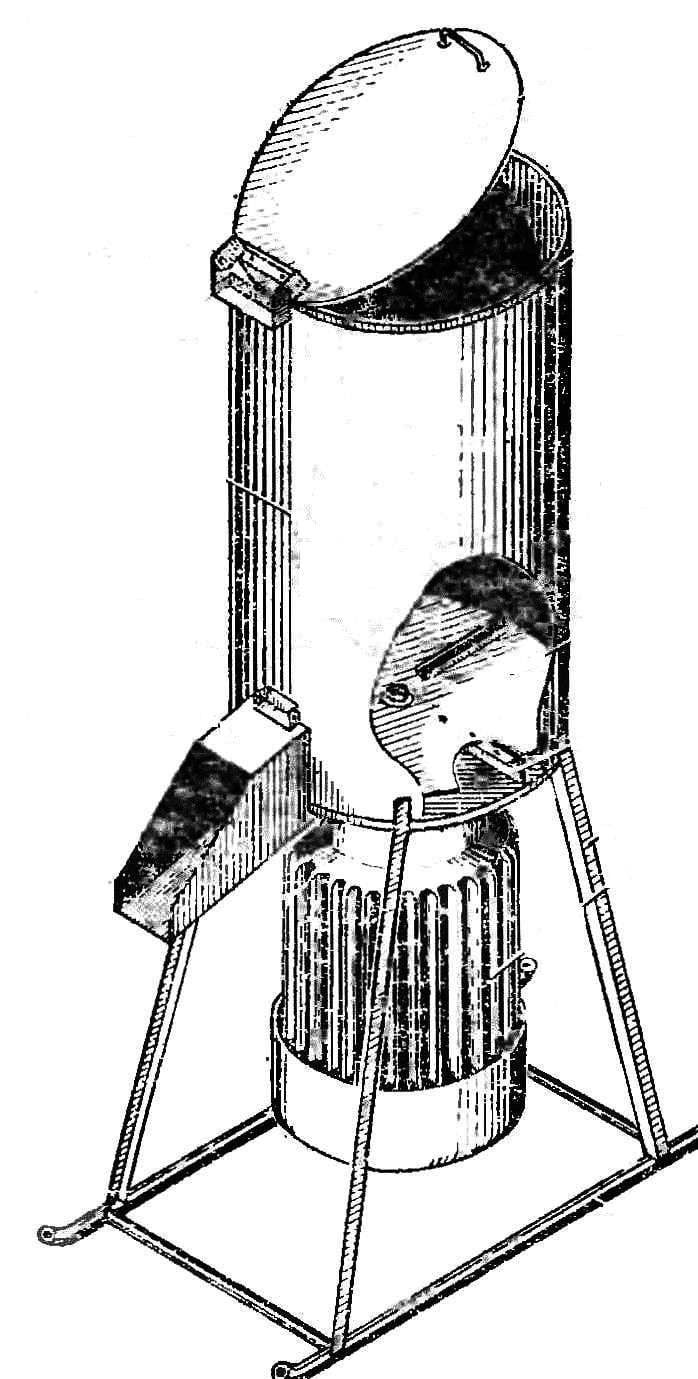

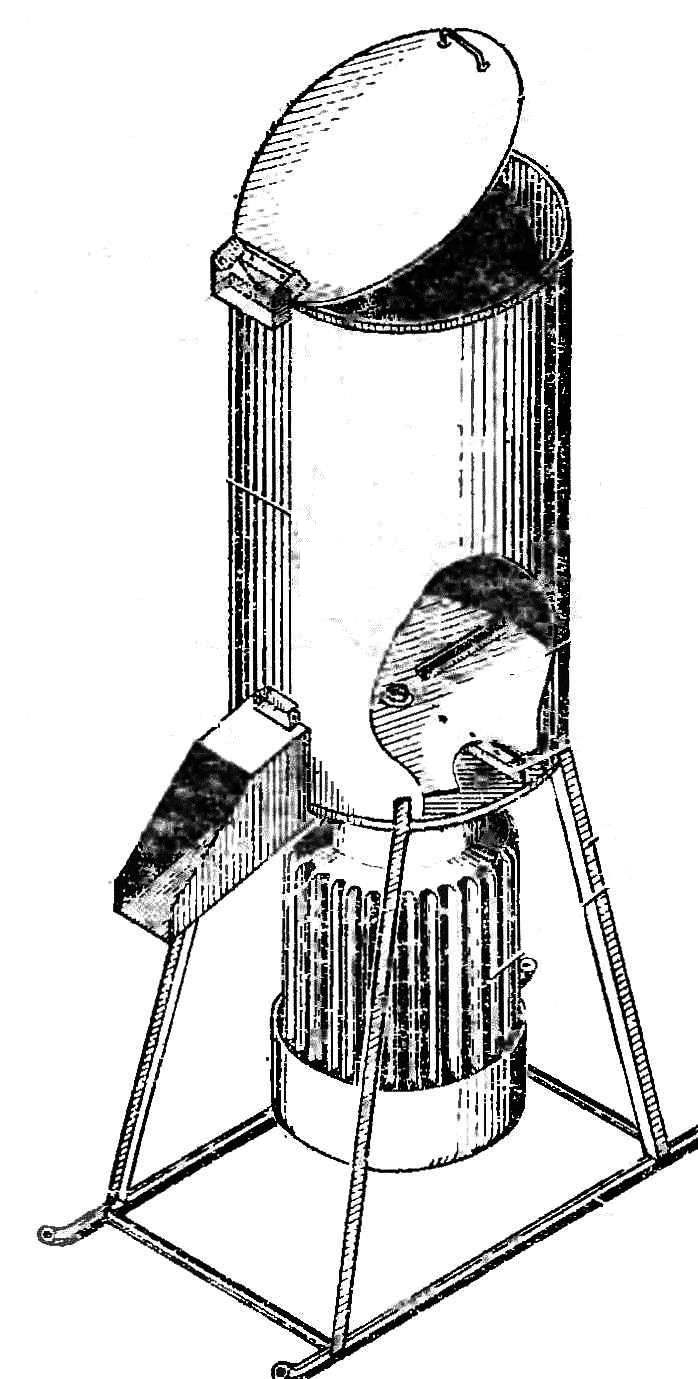

Preparation of feed for Pets will go much faster with electrothermy. Five minutes turns out two buckets of chopped vegetable mass — juicy supplements to straw, the Seine and other dry food. Design float is very simple. Working capacity is a large metal tank — ready or homemade. Roll of steel sheet with thickness of 1.5 mm cylinder ø 300 mm and height 500 mm, the upper part of the bead or turn over cut along the rubber tube. Fasten the hinge flip cover. From the bottom weld to the steel cylinder bottom from a sheet thickness of 4-5 mm. Drill in it five holes — Central, under the motor shaft and four for the mounting bolts. I used a three-phase motor power 1.1 kW at 1400 rpm. Its body with flange performance was very easy to attach to the bottom of the float. The hole in the tank is slotted at the junction of the bottom and side walls. Over it hung on the hinges of the box-shaped discharge tray. Four inclined legs made of steel angles 20 X 20 mm and length 150 mm more dimensions of the motor are welded to the bottom of the tank to the control slide of the segments of water pipes. Working knife grater is made of round steel disc with a thickness of 2-3 mm. in diameter should be 10 mm smaller than the inner diameter of the tank. With a hacksaw or abrasive cutoff wheel in the disk are cut two opposing radial groove width of 10 and length of 120 mm. Edge of each groove, counter to the chosen direction of rotation, bent up and sharpened with a file. Brushes to remove the crushed mass can be done by clamping a strip of thick rubber on a segment of the area. They are mounted on the bottom side of the working knife. Motor shaft is a disk fixed with the help of the hub. The easiest way to find for this purpose, the pulley with an appropriate sized keyway and drill the hub out of it.