As the capacity of the homebrew usually offer two hundred liter barrel, and mixing by rotation of either the barrel itself or the blades inside her. Drive— manual or motor through a chain (or belt) transmission and gearbox with a large gear ratio, for example, worm.

Both these methods, along with obvious advantages, have drawbacks. These units are quite heavy; often they move (closer to the mold) there are certain complications. In addition, manual methods of mixing the large mass of the concrete mixture or solution load Builder also considerable.

Motor drive eliminates this problem, but to make such a unit, not everyone has the opportunity-and the gear is nothing to sneeze at, and are expensive.

Want to offer a more simple option. When I needed a large quantity of structural concrete, I analyzed all of the above, began to look for the best option of making it subject to the following conditions: the maximum possible relief (compared to the “billed method”) by mechanization, simple structure and small material costs in manufacturing.

And that’s what happened.

As a working body (mixer) I used the drill mixer and construction equipment with a height 110 and a diameter of 100 mm. Drill a normal household, with a capacity of 400 W at a rotation speed of 600 rpm. Bin I was old linen tank with a capacity of about 30 l For discharge of the prepared solution I made the slipway turning hub.

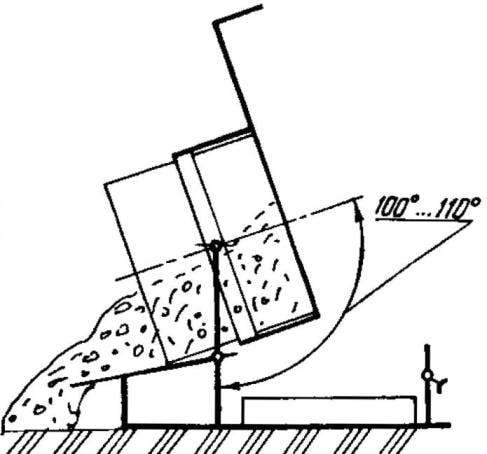

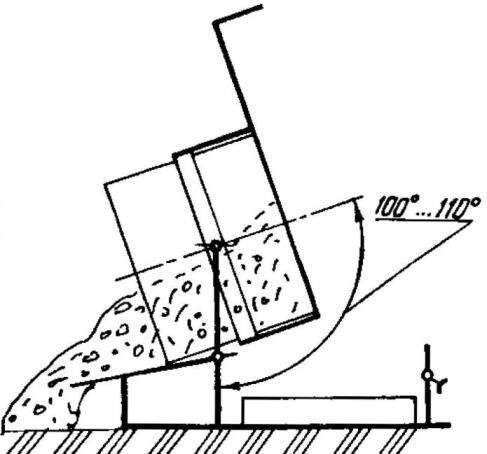

Diagram of plant for production of concrete (mixing, b— upload):

1 —working body of the mixer (construction mixer, purchase the item); 2-hopper (tank underwear); 3 — rotary has taken into account; 4 — bench; 5 — stand; 6 — formwork; 7 — tray; 8 — solution; 9 — drill

Stapel:

1 —front (steel, area 36×36, 2); 2 —bearing tray (strip 20×2, 2); 3 — kosina (strip 30×3, 2); 4—longitudinal element (area 36×36, 2); 5 — crossbar (area 36×36 2 PCs); 6— ring hinged bolt; 7 — emphasis (strip 30×3, L165); 8-the axis of the hinged bolt (bolt M8); 9—bushing (steel, 2 PCs.); 10 —nut-lamb M8; 11 — tilt bolt M8

The slipway consists of a base (two longitudinal steel longitudinal members connected by a pair of cross members), to which are welded two uprights with slots at the top under the semi-axis rotary unit. These details— from the corner 36×36 mm. reinforced Strut slopes from the steel strip. To the rear crossmember of the base welded vertically focusing with the hinge bolt used for fixing the rotary unit in the process of preparation of the solution.

Front to the Stoics attached to the guide tray of a thin sheet of aluminum, but made of tin (for example, from an old bucket), or even plywood. The tray is pivotally attached, to be able to put it on the upper end of the casing with discharging of the solution. Between the uprights and the stop has a small wooden deck — stand.

The main element of the rotary knot — wrap, to which are welded two half-axles (bolts M8 heads out). The Hoop is bent from the strip (but you can use ready-made area, for example, coupling flange round duct ventilation systems). From the bottom to the Hoop is welded (or riveted) U-shaped frame, which serves as a support for the hopper-tank. Mounted on the frame arm works as a lever when unloading, and its bent end is fixed to the focus while stirring the solution.

All the figures of the dimensions due to the dimensions of the tank (the linen tank; this tank has seemed to me most appropriate from the available). If anyone has the volume of one batch seem small, it is possible to use, for example, a shortened 100-liter barrel. The design principle will not change.

If you choose the basic installation options I proceeded from the following considerations. First, the height of the U-shaped frame (L) must provide the location of the axis of rotation at the center of the tank (or slightly below) — this will facilitate overturning during unloading. Secondly, the distance from the base of the pile to the hinge (H) should be sufficient to turn the bottom of the hopper is not ceppaloni for tray, stand and other parts. But to increase this parameter is not necessary, as the higher the bin, the greater the load on the hands during the mixing process, because the mixer will have to keep bent arms. In addition, increases splashing when unloading. Thirdly, the departure of the longitudinal elements of the base of the pile (l) should be minimal to be able to move up closer installation to the formwork (but sufficient to ensure stability of the unit).

Stand:

1 —support (bar 50×50, 2); 2-(Board s20)

Swivel:

1 — pole hopper (strip 30×3); 2 — Hoop (strip 30×3); 4 — the lever (strip 30×3); 5 — bracket axle (area 36x36x4, 2 PCs.)

Technology solution preparation — the usual. To download components, preferably in small portions — a quarter or a third of the total, to get “layer cake”. This will speed up and facilitate the stirring (the linen tank includes 2 buckets of sand and 0.5 buckets of cement).

First, mix dry to mix until uniform dark grey color (it takes 3-4 min), then add water (approximately 6 litres) and stirred with a mixer to obtain a creamy mass (5-6 min). Roll-over hopper, such a solution is discharged almost completely. For extracting residues, you can use a special scraper, like an old shovel, cut it a working edge radius of the bunker.

So, in result I got such a mechanism, which I wanted. First of all, it reduced the labor intensity and physical activity, improved performance of solution preparation (of course, compared to “billed”). The installation turned out easy (not more than 10 kg) and mobile, to move it in whole or in part — how convenient. Manufacturer of the bench with swivel node does not require large material costs (I had 3.3 m area and 3 m strip steel), and welding Assembly did not take much time.

V. USTIN

Recommend to read THE WING ALONG THE FUSELAGE A distinctive feature of this model of rocket plane is turning the wing. It is set along the fuselage, which eliminates any possibility of the appearance of the spiral during takeoff. ... WITH AEROBRIGADA – SPEED CORD Today we offer young modelers rather unusual development of high-speed cord models apropriada. Novelty design in unusual approach to design. Perhaps this is an approach based on the full...

Anyone who self built a house, garage, cottage, etc., knows that the most difficult stage — zero cycle (the Foundation) associated with the preparation of a large number of concrete mix or mortar. Of course, if you have a mixer, then everything is easier and simpler. But to buy such an expensive setup for short-term use is expensive and knead with a shovel in the trough is not very desirable. Way to make the mixer itself. In the “Modeller-designer” there have been several publications on this topic.

Anyone who self built a house, garage, cottage, etc., knows that the most difficult stage — zero cycle (the Foundation) associated with the preparation of a large number of concrete mix or mortar. Of course, if you have a mixer, then everything is easier and simpler. But to buy such an expensive setup for short-term use is expensive and knead with a shovel in the trough is not very desirable. Way to make the mixer itself. In the “Modeller-designer” there have been several publications on this topic.