The soil on our garden plots is such that during plowing with ordinary plows, clods are formed that require considerable effort and time to prepare the land for sowing. But people don’t give up. Many not only adapt but also involuntarily become innovators.

One of my neighbors, for example, modified the plow body by installing a share for non-moldboard soil loosening on its right side. Having convinced themselves of the advantages of such modernization, others followed, including me.

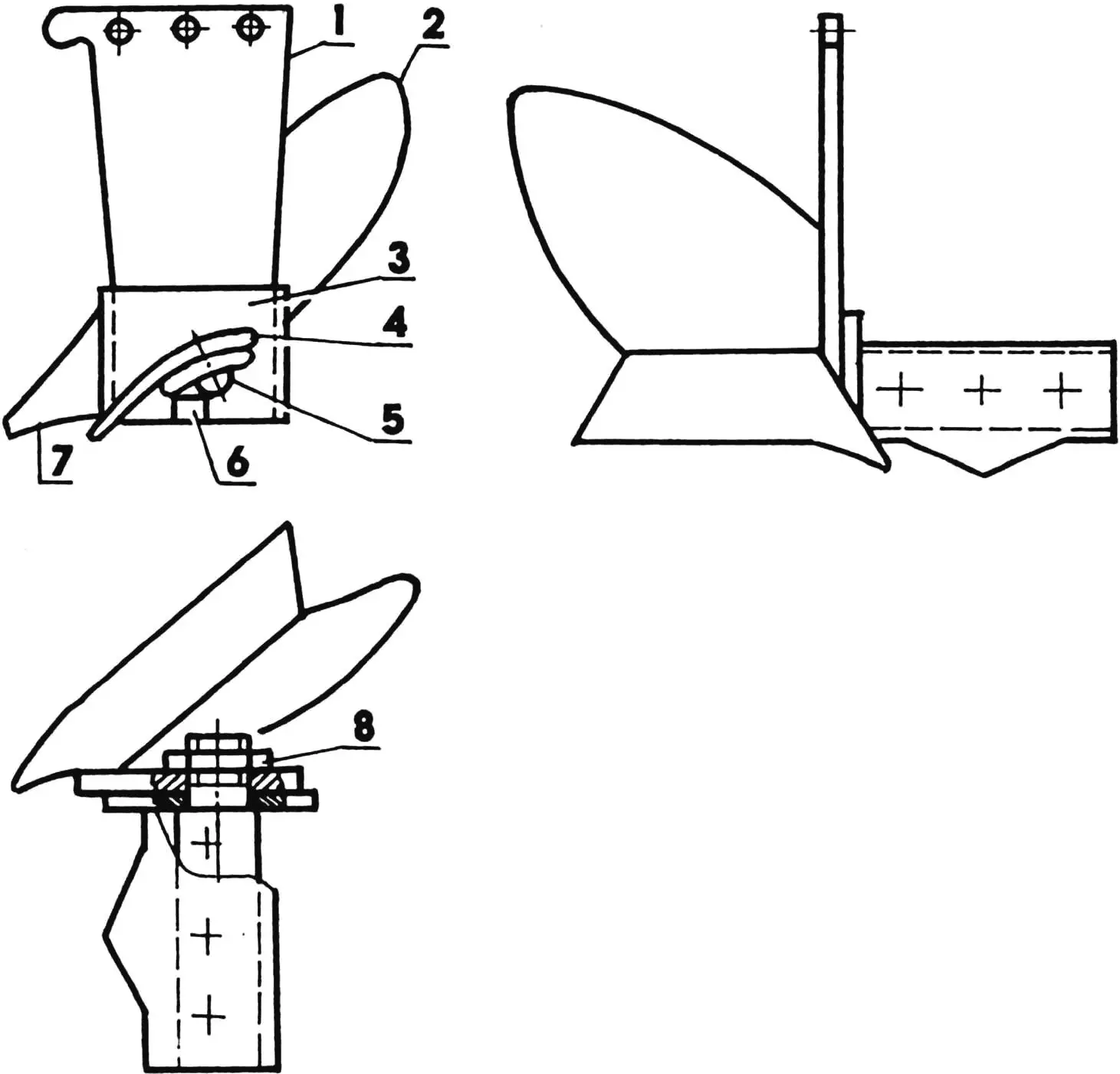

The body of an ordinary plow consists of a stamped stand, a share, a moldboard, and a mounting casting. On the modified one, an additional share is installed with its convexity outward. In its middle working part, there is a penetration toe resembling a triangle.

The additional share is fastened on a support screwed to the casting with a shaped nut. And to eliminate even the slightest rotation here, a stop is provided.

The width of the additional share is 80 percent of the main share’s width at the same depth. The total draft resistance of the plow is reduced by 30-40 percent. As practice shows, the service life of the main share is also significantly increased.

1 — stand; 2 — moldboard; 3 — casting; 4 — additional share; 5 — support; 6 — stop; 7 — main share; 8 — shaped nut, “tacked” by welding.

But the main thing is that the quality of plowing noticeably improves. The soil layer cut by the additional share is loosened. Turning over during the next pass of the plow, the soil becomes fine-structured. The root system of weeds is destroyed, and crop residues are plowed to the bottom of the furrow.

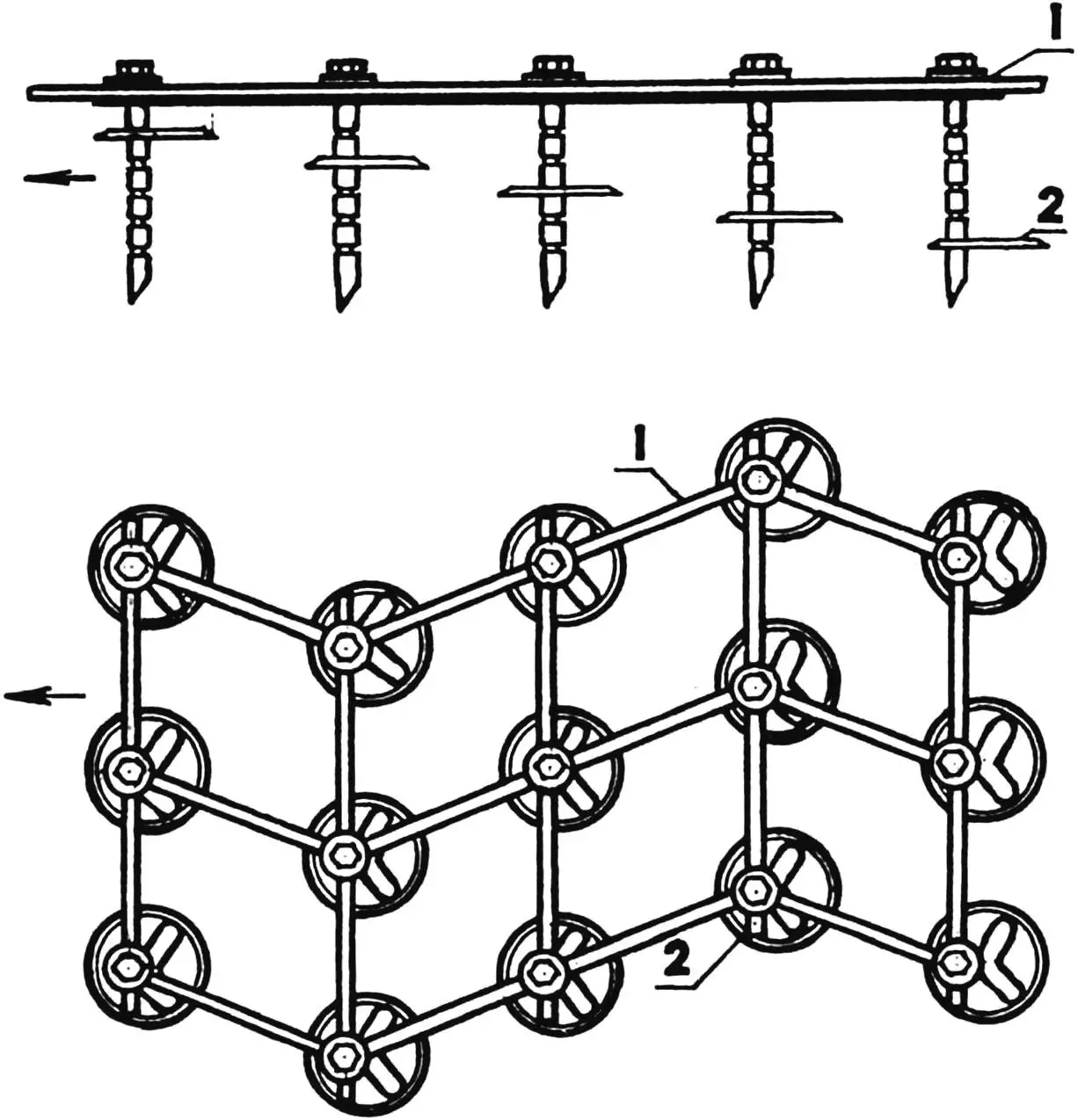

I also adopted another neighbor’s innovation—a harrow with the capabilities of a cultivator and a loosener. For this, five circular grooves are made on each tooth of the harrow (according to the number of teeth in the direction of movement). The grooves are mounting places for additional working organs, each of which is a sharpened steel disc. A hole is made in the center of the disc with a diameter slightly larger than the diameter of the circle described around the cross-section of the tooth.

Three radial slots extend from the center of the disc, with a width slightly larger than the diameter of the grooves on the tooth, but smaller than the diameter of the described circle.

The discs are located in the grooves of each tooth, lowering as they move away from the front edge of the harrow. Such a stepped arrangement of blades is desirable but not mandatory: depending on the agrotechnical requirements for soil preparation, other options are possible.

During the operation of the combined soil-working implement, the teeth perform their usual function. However, unlike a standard harrow, they stably maintain the set depth of soil treatment (this is facilitated by the asymmetric sharpening of the discs).

Simultaneously with harrowing by the teeth, the discs cut the roots of weeds and crush soil clods. This cultivator operation is performed across the entire width of the harrow’s working width thanks to the zigzag arrangement of working organs on the harrow frame.

1 — base harrow with grooves on teeth; 2 — cultivator discs (up to 25 pcs.).

Since the recommended option is five-level, multiple weed cutting and multi-tier cultivation occur, accompanied by soil loosening to the depth of the lowest discs. Moreover, all this is done without bringing moist deep layers to the surface of the earth.

With free—without rigid fastening—placement on the teeth, the discs maintain a horizontal position. Moreover, their breakage is prevented in case of encountering stones and metal objects on the treated area.

Of course, the discs gradually wear out (on the front of interaction with the soil—on the length of the circumference corresponding to a sector of approximately 120°). But they can be reinstalled twice on the teeth using the slots, putting the next sector into operation. This achieves a large resource of work for additional working organs.

As accumulated experience shows, a harrow equipped with blade discs can successfully work in a hitch with other agricultural implements. In our garden cooperative, it is widely used not only for pre-sowing soil treatment but also for fallow raising. And in some cases, it can even replace stubble cultivation and plot cultivation with flat cutters. Get an improved harrow—you won’t regret it!

«Modelist-Konstruktor» No. 5’2000, A. TIMOSHENKO, Feodosia, Ukraine