Indeed, for the manufacture of power tillers needed only powertrain “motor—wheel” scooter “Electron” (hence the name “Electronics”), a few water pipes and a few more details. With the powertrain is taken almost without alterations. Therefore, ideally, this option is possible: the gardener comes to his land on a bike with a trailer, which contains frame, additional wheel and lugs; rearranges “the motor wheel” on the frame and processes the resulting the tillers of the ground or landing. In the end, returning to their seats, leaving home again on a bike.

Frame Assembly:

1, 2 —left and right side members (steel pipe 26,8×2,8), 3 — shell clutch cable, 4 — bed fuel tank (strip 20×4,5), 5 — bed fuel tank (rod 0 8), 6 — conduit “gas”, 7 — mounting bracket sheath “gas” (area 30x30x3), 8 — wire throttle, 9 — shift lever bracket transmission, 10 — bolt M8 bracket, 11 — shift lever (rod Ø 16, L150), 12 — pull back (dural tube 14x 1,5), 13 – rocking chair 14 — thrust front (dural tube 17×1,5), 15— lever “gas”, 16 — strut (steel tube 21,3×2,8), 17, 20 — rail control right and left (steel pipe 26,8×2,8), 18 — cross bar (steel pipe 26,8×2.8), 19 — traverse (area 32x32x4), 21 —pull the clutch lever 22, the mounting brackets of the shell of the clutch cable (area 50x32x3), 23 — emphasis (area 35x35x3), 24 — stiffener (steel sheet s), 25 — slide, welded (area 35x35x3).

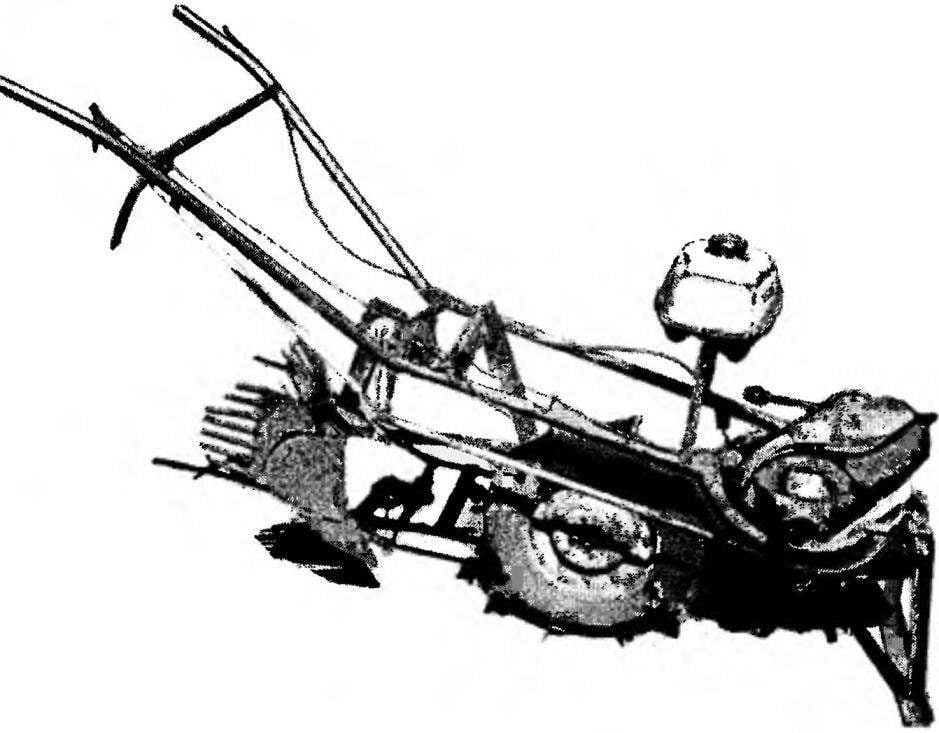

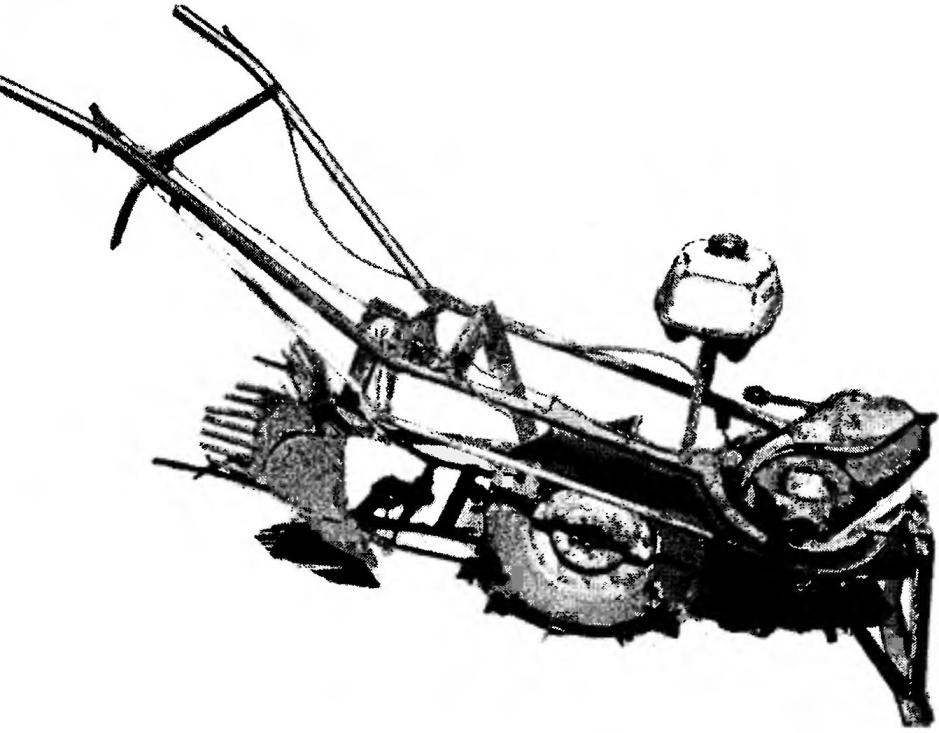

Motoblock “Electronics”:

1 — engine (scooter Elektron), 2 — stand, 3 — resonator exhaust pipe, 4 — arm pendulum power unit (scooter), 5 — star leading (z=8, t=19,05), 6 — circuit power (t=19,05), 7 — grouser, 8 — sprocket driven (z=39, t=19,05), 9 — wheel (scooter), 10 — cultivator, 11 — pole (area 40x40x4,5), 12 — strip curved (strip 25×6,5, Ь450), 13—bracket mounted implements, 14 — болтМ14 attachment of the mounted equipment, 15 — stirrup, 16 — bolt M8 fixing support (2 PCs), 17 — frame, 18 — fuel tank, 19 — filter sump with tap, 20 — air filter (from a motorcycle “Genone”),

Node sprocket:

1 — the output shaft of the engine, 2 — wheel hub slotted (regular stars), 3 — star, leading (ST5, z=8, t=19,05), 4 — screw locking M8 (2 PCs), 5 — shaft (ST5).

The site, driven sprocket (the one-wheeled version of the walk-behind tractor):

1 — sprocket driven (ST5, z=39,t=19,05), 2 corps (ST5), 3 — hub slotted (regular stars).

Node sprocket:

1 — the output shaft of the engine, 2 — wheel hub slotted (regular stars), 3 — star, leading (ST5, z=8, t=19,05), 4 — screw locking M8 (2 PCs), 5 — shaft (ST5).

The site of attachment of the mounted equipment:

1 — bracket (from the farm), 2 — three, 3 — slide, 4 — crossbar tillers, 5 — grip attachment tools, 6 — bolt M14 with nut, 7 — nut and locknut M12, 8 — bolt locking M10.

Upgraded propolis:

1 — grip, 2 — catcher tubers (6 PCs.), 3 — screws “Nosara”, 4, “Nosara”.

Rear axle (two-wheeled walking tractor version):

1 — shaft driven (ST5), 2 — sprocket driven (ST5, z=39, t=19,05), 3 — bushings-plain bearings (bronze), 4 — washers (s2) 5 — spacer (STZ).

The same alterations suffered by the power unit, very low. First cover linkage mechanism was rotated 120° for more convenient accession to the control cable. Second, to the segment gear boxes welded shoulder length 72 mm with lugs under the control arm — it became much easier to enable transmission. Thirdly, straightened the inlet fitting, so that when the inevitable sharp and steep slopes of the carburetor, equipped with Vozduhoflotsky a motorcycle “Panonia”, worked without a hitch.

Since the mode of operation of the cultivator requires other * gear ratios was replaced by a homemade nodes of driving and driven sprockets. The first includes hardened splined hub welded to it with a new drive sprocket and tapered shaft with flat turn key on a 32 mm Conical neck shaft is designed for landing on it the belt pulley that runs to the compressor. The latter (taken from the brake system of the vehicle ZIL-130) can be attached to the front tillers and used for spraying plants or painting any surfaces (not shown). Node driven sprocket has the same hardened hub, bushing-housing and new driven sprockets, welded together.

Altered thus the power unit are connected with the frame made out of water pipes 26,8×2,8 and partially 21,3×2,8 mm. Left side rail made straight, right — curved tracks around the motor housing. Front they both flattened for the formation of endings, in which are drilled four holes: one pair of coaxial holes designed for hanging the unit “motor—wheel”, the other, coupled with angled rests for the folding stand, holding the tillers parked in a vertical position.

Closer to the middle spars are welded to the bed stand fuel tank. Stand slightly tilted back relative to the frame so that when the Parking lot or the walk-behind tank (from a moped “Riga”) occupied a horizontal position and the fuel was supplied smoothly.

End the side walls are angled crosspiece and the tubular crossmember. Attached to the crosshead bearing, which gives rigidity tillers, because along with a pendulum arm and the frame, it is the power triangle (the upper rows of holes in the support to fit handrails control the height of the operator). The cross member also serves as a seat for bracket mounted implements (for more details about this node below).

For spars at an angle of 30° thereto, are handrails control, also from the water pipes. They carry on the left and the clutch lever, right lever to adjust the throttle. Between handrails welded tubular strut, which is screwed to the lever, the traction wiring associated with the segment transmission (axial play in the transaction is selected by adjusting the rear traction).

The ends of the handrails “electronics” have arms (the operator holds onto bare metal is not very convenient, especially during plowing when the tillers are the most fractious and volatile; it is better to wear any arms, at least from a motorcycle handlebar).

Now back to the attachment point mounted implements. It consists of a slide bracket connected to the stapes. The latest from bent steel rod with a diameter of 12 mm, at the ends it is threaded M12. The slider is welded from two parts, provided with a locking bolt M10 and put on the cross member of the frame when it is assembled. Bracket taken ready-made (agricultural machines); in his body there is a rectangular hole in which to enter a handle, say, a plow and is held by bolt M14.

Such construction of hanging node gives the gun three degrees of freedom, i.e. it can be adjusted vertically (bolt M14 bracket) and within a narrow range of horizontal and corner along and around the axis of the crossmember (M10 locking bolt of the slider). The last adjustment — angle — step, step it sets the holes at the end of the curved strap, rigidly fixing the implement in a selected position.

Mounted implements for “electronics” three; plow, cultivator and protolytic. The first two are standard, no modifications. Yes, and they are used for their intended purpose. The latter is used more in the role of vicariates potatoes, supplemented with tubers catchers — steel bars of 10 mm diameter, are welded in three rows. For weed control grip propolice re-install it, as expected in such cases — vertically. The legs of his function — cut the roots of weeds, traps tubers it does not work.

To harvest the grip rotates back to the maximum angle that the tabs of propolice stood almost vertically and acted as a shovel, digging up potatoes. The catchers while sifting through earthen clods, capturing the tubers and raked into piles only to collect them in bags.

While working with mounted guns on wheels “electronics” to put on lugs (two sizes), collected from strip rim, angled rungs and cheeks. When plowing, cutting and backfilling of planting furrows, weeding and hilling of landings used with the grouser bars, having a length of 102 mm (one-wheeled version of the tillers). When digging potatoes — lugs with crossbars with a length of 145 mm (two-wheeled version). In this case, the wheel is removed, will be removed and regular axle (with ball bearings 204), and in its place is installed the rear axle, is made of three steel parts (shaft, driven sprocket, spacer) and two bronze sliding bearings. The latter are lubricated using a grease gun, screwed in a specially drilled for it, the threaded hole in the housing of the pendulum arm (between the bearings).

Option two-wheeled walking tractor (with or without grousers) applies and for transportation of a cargo truck that can withstand operator plus six bags of potatoes is about 400 kg (the trolley will be published later).

Since the motor scooter quite unpretentious, its maintenance is reduced to periodic lubrication, cleaning and fuelling. Start it first kick, it was subsequently established tractor magneto.

Finally I must say that the soil on the banks of the river Big Zelenchuk heavy, replete with stones of various sizes — from small pebbles to boulders. The stones, as they do not move like the people in the ground every year. Nevertheless, “Electronics” is not blunted them on your plow working properly, and, no doubt, still serve their Creator.

A. TIMCHENKO

Recommend to read ON THE HANGER — STRAPS Even if the door to the closet (the wardrobe) a rod hanger — it is more suitable for shawls, scarves, and even ties, but not for belts: they always slip off because the buckle like the... SAVED THE VEST FROM MATTRESS If you have an old inflatable mattress, consisting of several independent sections, it is easy to adapt as life jacket for boating. You will have to sacrifice one of the middle sections,...  The story of all machines and mechanisms created by Amateur designer from the village of Zelenchukskaya, Karachayevo-Cherkess Republic, Vasily Alekseevich VERBELEN, one post could not contain. Better to talk about them in turn. And we will begin, perhaps, with the most simple what built the craftsman —tillers “Electronics”.

The story of all machines and mechanisms created by Amateur designer from the village of Zelenchukskaya, Karachayevo-Cherkess Republic, Vasily Alekseevich VERBELEN, one post could not contain. Better to talk about them in turn. And we will begin, perhaps, with the most simple what built the craftsman —tillers “Electronics”.