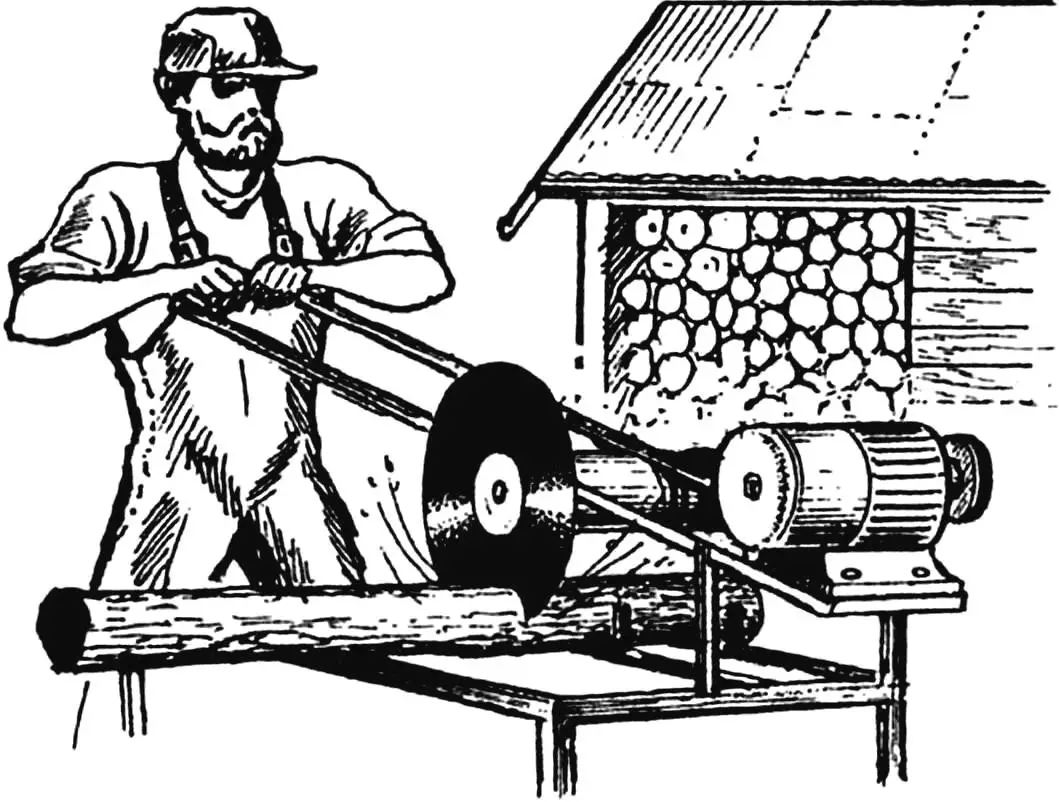

The proposed machine is designed mainly for recycling dilapidated wooden structures into firewood. Due to the many nails sticking out everywhere, this waste material is beyond the capabilities of the “Druzhba” chainsaw, and therefore costs mere pennies. The cheapness, of course, is attractive. What stops you is something else: what and how to cut such a conglomerate of old boards, beams, and logs bristling with “rust”?

An unpretentious circular electric saw with self-sharpening teeth came to the rescue.

It consists of an electric motor unit and two mechanical units: a base frame (with a protective visor-handle) and a pendulum frame with a saw blade. Simplicity is the key to reliability. Over more than 20 years of fairly intensive operation (many of my friends, acquaintances, and neighbors also needed firewood and wood cutting), the compact electric saw has not had a single breakdown!

For those who decide to make such a reliable machine for themselves, the features of this design are probably of interest. The steel saw blade is symmetrical, that is, with equally profiled teeth, each of which is maximally close in shape to an equilateral triangle. The recommended length of the cutting edge is 20 mm.

When meeting a nail at high speed, such a saw undergoes plastic deformation of the tooth tips in the direction opposite to the direction of disk rotation. Acting repeatedly, this deformation gives each tooth the shape of a curved pointed beak. A kind of self-sharpening occurs, which can be used after reinstalling (with flipping) the saw blade. The bends are now directed in the direction of disk rotation. So when sawing wood saturated with nails, the blade has to be flipped repeatedly. A similar situation is observed during prolonged work with freshly cut oak, larch, and logs from other hardwoods.

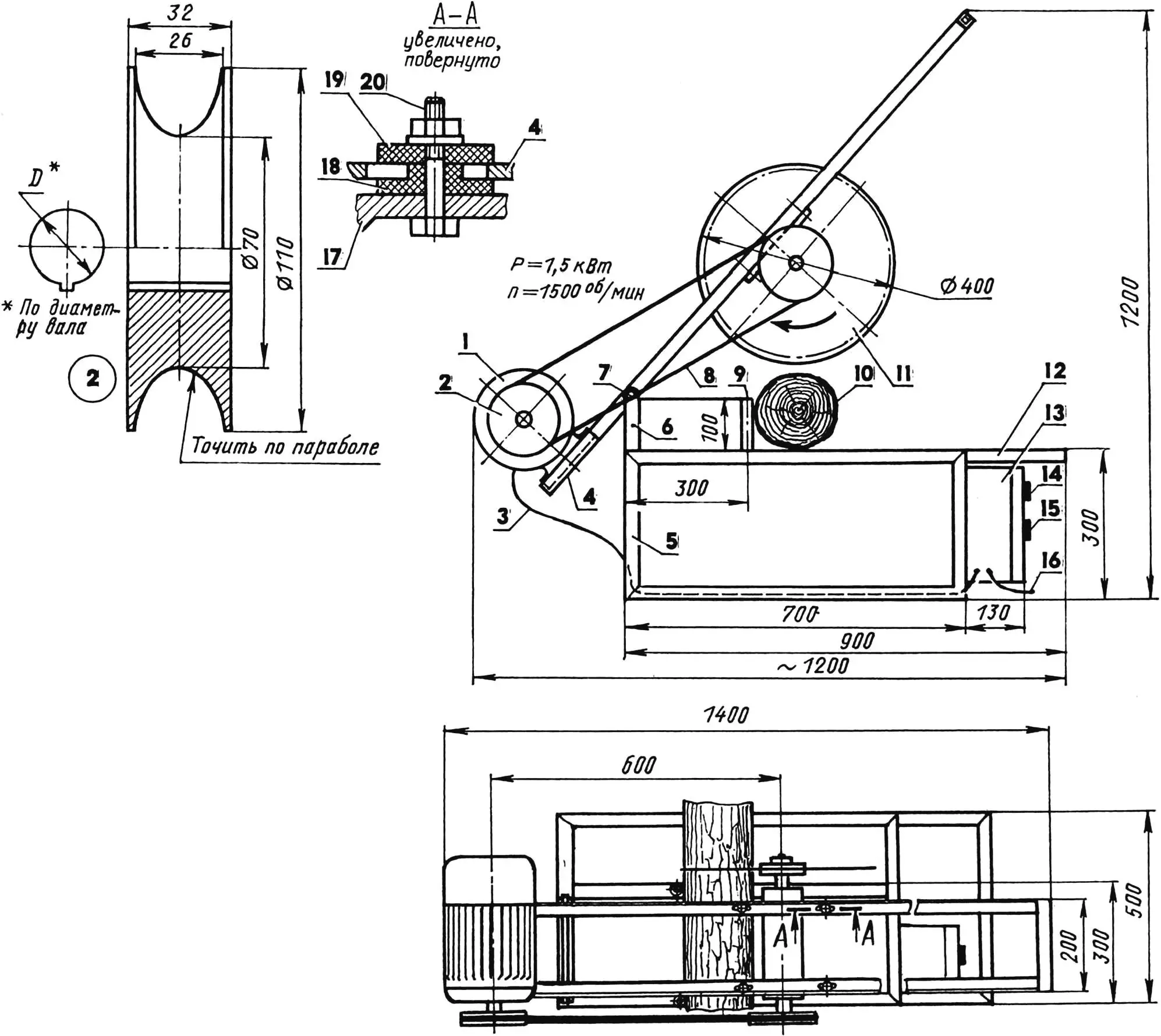

1 — electric motor; 2 — single-groove pulley, parabolic (2 pcs.); 3 — three-core cable with reinforced electrical insulation; 4 — welded pendulum frame (on the top view it is conditionally horizontal); 5 — base frame; 6 — bracket (2 pcs.); 7 — pendulum frame axis (with washers and cotter pins at the ends); 8 — V-belt; 9 — stop (2 pcs.); 10 — log; 11 — saw blade with bearings; 12 — visor-handle; 13 — control unit; 14 — STOP button; 15 — START button; 16 — cable feed; 17 — bearing housing foot; 18 — damping bushing; 19 — damping washer; 20 — M10 bolt.

Like most circular saws, the saw blade of the machine in question is mounted on the driven shaft with two flanges and a nut with left-hand thread. The torque is transmitted to it from the electric motor through a V-belt drive. Belt tension is adjusted by moving the shaft supports along the pendulum frame with subsequent fixation with M10 bolts.

The pulley grooves are turned on a lathe. The working profile of each is a parabola. As practice shows, a V-belt with such pulleys serves without replacement for more than 20 years even in homemade designs where it is difficult to maintain alignment.

Naturally, when performing any sawing work, care should be taken. A protective visor is provided to protect the starter box from impacts. It also serves as a handle when carrying the machine by two people. The free end of the pendulum frame is also made in the form of a handle.

The electric motor installed on the pendulum frame is a three-phase asynchronous motor. With, according to passport data, a power of 1.5 kW and a rotation speed of 1600 rpm, it provides transmission to the saw blade of a torque sufficient for cutting, say, a beam (with identical pulleys and an unworn V-belt) at almost stable 1480 rpm.

My electric saw was initially powered from a single-phase household AC network with a voltage of 220 V according to a circuit published in the magazine “Modelist-Konstruktor” No. 2 for 1996. But then I had the opportunity to connect it to a three-phase network. The operational characteristics of the motor (as well as the saw as a whole) noticeably improved.

In conclusion, a few words about the rest of the electrical equipment. Cables should be highly reliable, with double insulation. Special attention must be paid to the tightness of the box with starter equipment, protecting the latter even from the smallest sawdust. One should not forget about the serviceability of the terminal block on the electric motor and measures to seal with elastic sealant the places where cables pass through metal parts of the structure. And, of course, strictly observe the rules of electrical safety and fire protection. Technology does not forgive carelessness.

«Modelist-Konstruktor» No. 9’2000, V. RADKOV