For industrial use trucks doing various capacities. As a General rule, plant as light-duty use, for transshipment of cargo between objects — medium-duty, and long distance (“long-range”) transport— powerful semitrailer tractors.

For industrial use trucks doing various capacities. As a General rule, plant as light-duty use, for transshipment of cargo between objects — medium-duty, and long distance (“long-range”) transport— powerful semitrailer tractors.

All of this is presented in the home farm, but, so to speak, in miniature. For example, for transportation within the economy will fit even car. For the delivery of goods from afar, you can hire the truck. But when transporting heavy loads over medium distances a car is unproductive, and the truck is unprofitable. And because their household, I decided to make a trailer and such that as the tractor it can be to use a walk-behind tractor, and if necessary — and a car.

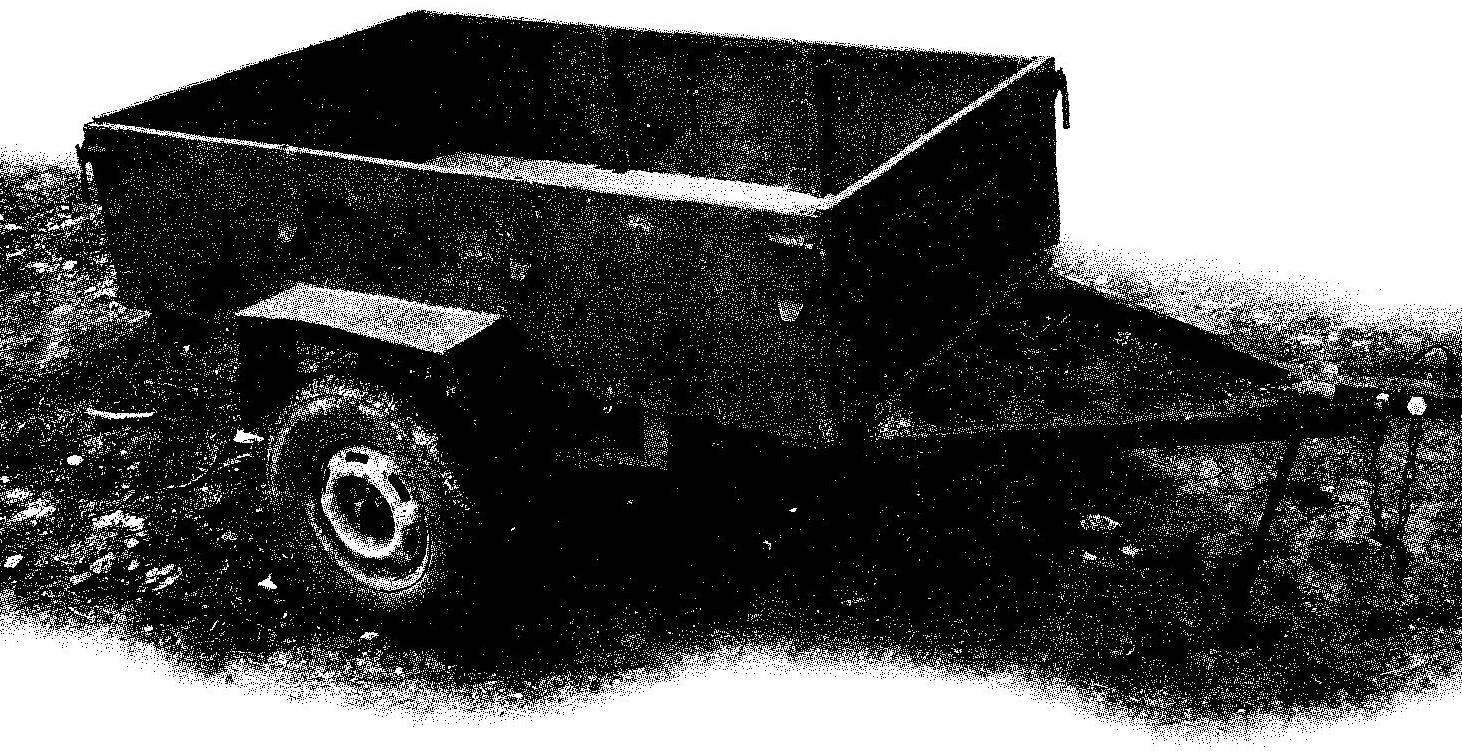

Trailer single-axle (two-wheeled), classic layout and very simple design. In addition, the materials used in the construction of the trailer, that the workman always has in stock.

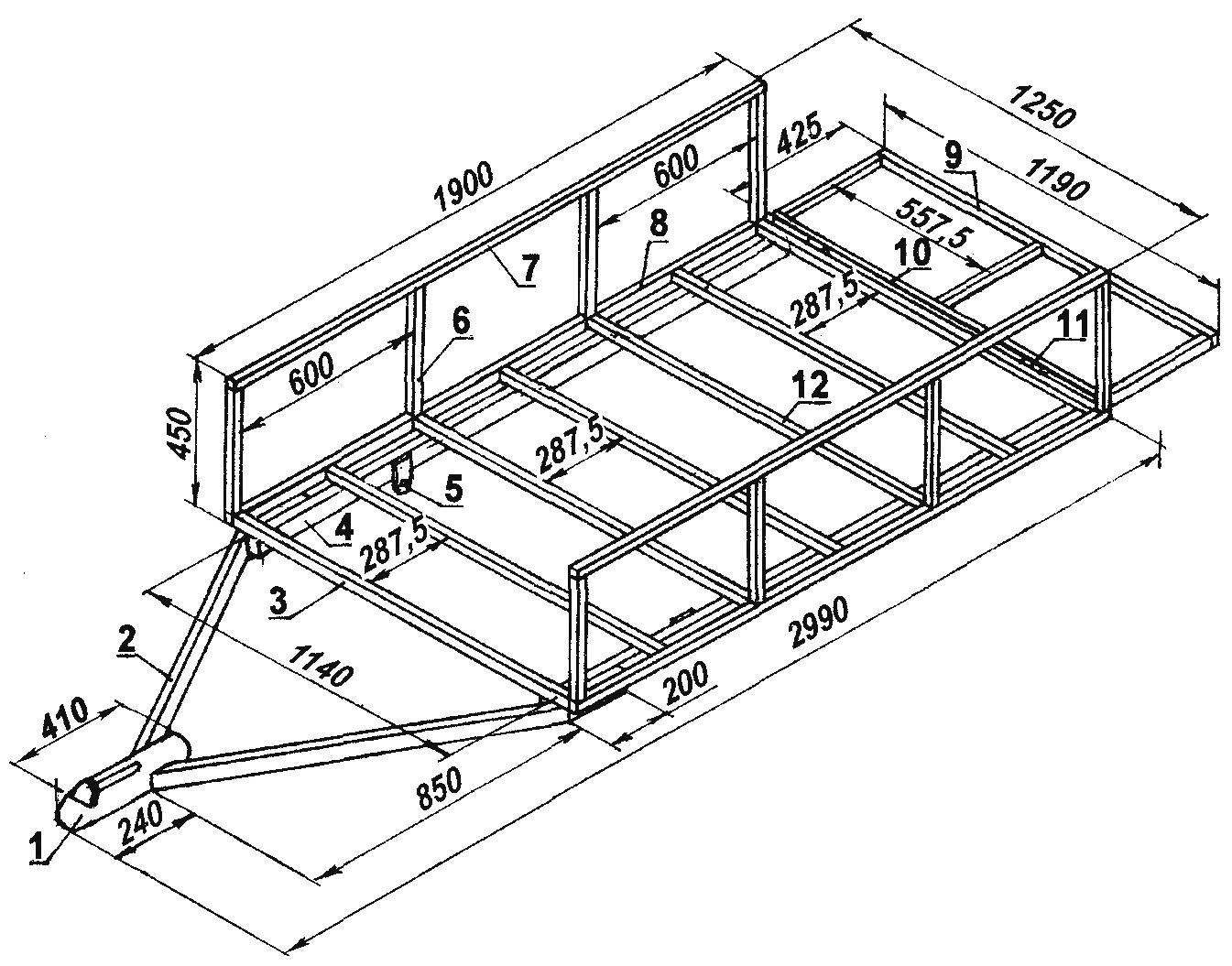

The frame of the trailer combined with the frame bars of the body (think of it as an integral body: to allocate one to another is rather arbitrary). Frame formed by two side members and a pair of traverse (front and rear crossbars). Five cross members located between the traverses can be constructively attributed to the grid platform. Traverse and cross spars have relatively small console releases. To the ends of these releases on both sides welded to the longitudinal elements, serving both the bottom trim frames of sides: on the elements installed and welded on four racks (one crossbar), and it is the upper trim.

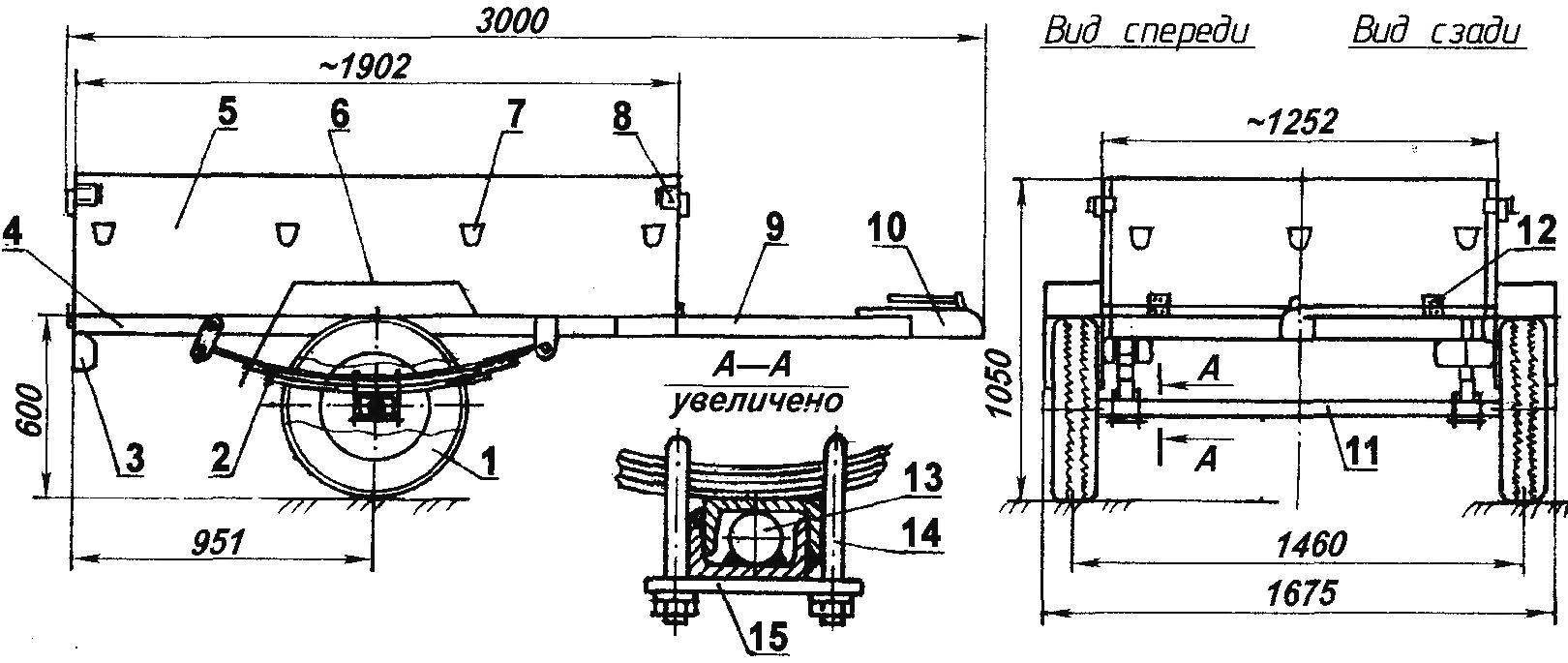

Fig. 1. Single axle trailer:

1 — the wheel (from the car “Moskvich-412”, 2); 2 — spring (from the car “Moskvich-412”, 2); 3 — signal lamp (purchased product, 2); 4 — spar frame (2); 5 — side Board (2 PCs); 6 — wing (sheet s1,5, 2); 7 — hook (sheet s1,5, 14 ). 8 — locking device (4x); 9 — pole; 10 — towing device; 11 — axle beam (channel № 5, 2); 12 loop drop side (4 PCs); 13 — wheel axle (steel 45, range 30, 2); 14— step ladder with lock washers and M12 nuts, 4 sets.); 15 — spacer (steel sheet s5, 2 PCs.)

Fig. 2. The frame and the body frame of the trailer (frame and headboard not shown):

1 — the towing device; 2 — beam beam (tube 60×30, 2); 3 — yoke (tube 25×25, 2); 4 — spar (tube 60×30, 2); 5 — eyelet leaf springs (steel sheet s5, 4x); 6 — front side (tube 25×25, 8 PCs); 7 – upper rail side wall (tube 25×25, 2); 8 – bottom rail side wall (tube 25×25, 2); 9 — top rail rear (front) side (tube 25×25, 2); 10 — bottom rail rear (front) side (tube 25×25, 2); 11 —a hinge (4 PCs); 12 — cross member (tube 25×25, 5 PCs.)

The side members are made of tubes of rectangular cross section 60×30 mm. still other of the above parts of the frame and the body frame (yoke, crossmember, rack, strapping) from a steel pipe square section 25×25 mm.

The front and rear of the bulkhead are the same. They are made by folding (this allows you to carry on the trailer long goods), but because of their framework, although all made from the same square tube 25×25 mm, but is made separate from the frame body. Grid platforms on top of closed 2-mm dural sheet forming the floor of the truck, and boards outside is covered with a thick sheet — steel of 0.8 mm sheet. Paul dragged to the bars with M5 bolts with countersunk heads and trim the sides carefully (points) are welded to the studs and uprights.

Beam axle also has a tubular rectangular cross-section: it is welded from two identical segments of channels No. 5, inserted one into the other. Previously at the ends of one of them welded the two wheel axles. The gaps between them and the channels of the beam ends were closed by plates of sheet steel.

The beam connected with the side members of the frame by means of two leaf springs, used from the old car “Moskvich-412”, from the same machine taken and 13-inch wheels. Mid-spring secured to the beam with step-ladders and to the side members attached to their ends: one put on the axle bracket and the other on the axis of earrings. The shock absorbers in the design of simplified truck trailer deem unnecessary.

Simple roomy trailer with folding front and rear sides

When such a suspension the distance from the ground to the platform was about 600 mm, which, as shown by operation, is quite acceptable.

The trailer hitch dual beam. Made of the same rectangular tube section 60×30 mm and spars. The rear ends of the beams of the drawbar docked and welded to the front ends of the spars with a 200-mm overlap. The front ends of the beams converge on the body of the towing device and is also welded thereto. It is my homemade, but with my trailer I never go on public roads (Yes this is necessary). Technical requirements simply prohibit the use of a homemade trailer hitch.

No trailer brakes — used to stop or slow speed the brakes of the tractor. But signal devices — lights taillamps with turn signals and brake lights set — that my actions were always clear to the partners on the road.

V. KURAKIN, Saransk