Deserved popular, for example, centrifugal crumbler (see Fig. 1). The principle of their action, and design in many ways reminiscent of the well-known elektrokofemolke. The grain is destroyed by knives rotating at a high speed, intense it cut occurs at the walls, where the raw material is thrown by centrifugal force. Quick adjustment of grinding is not provided here (see table.); the size of the cut fraction is determined by the mesh, and performance — sharpness of knives, their size and speed.

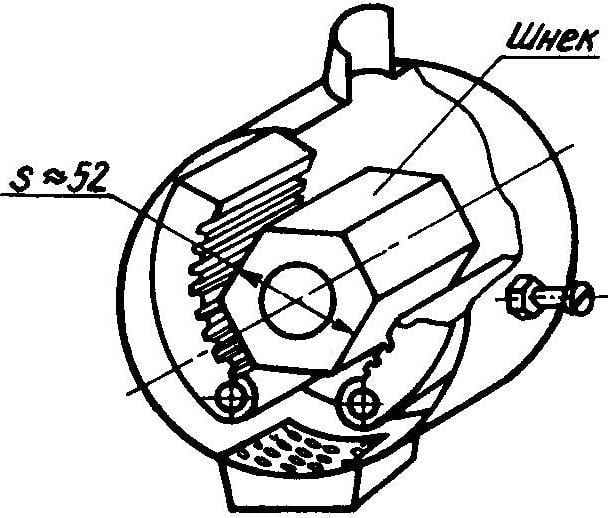

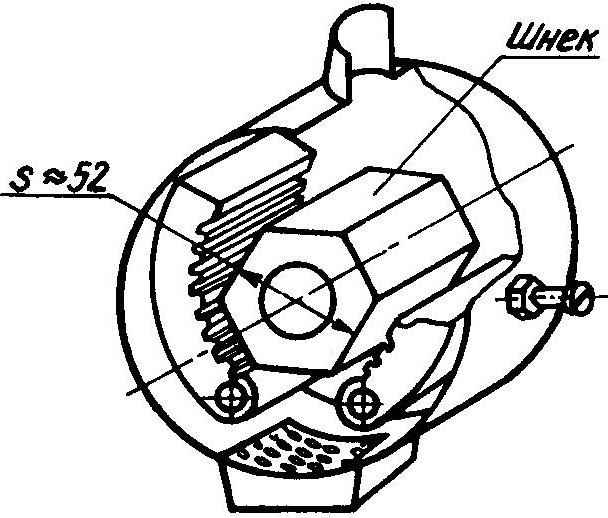

In a screw Shellers is cut, and the grain crushing due to the rotating steel polyhedron (typically a hexagon or in some improvised structures — the splined part of the driveshaft) and pads with hardened splines. Wherein the resulting product is typically moved along the axis, which contributes to the displacement of the exit wound forward relative to the input hopper. Main disadvantages: the dullness of the faces, resulting in poor performance and the lack of a clear gradation of sizes of the obtained fractions due to the release of poorly milled grains in the moments of occurrence of “zero angle” of the working faces. More sophisticated design with a screw (as in food grinder) screw, but they can be attributed to the combined shredders, screw for after here involve a knife.

Grind grain, acorns and other raw materials is not a problem, if you make any of the designs, based on the interaction of centrifugal forces of the rotating blades (a) or screw (b), burrs (C), rollers (g) and any of these combinations

Comparative characteristics of the Shellers common types

At the mill Shellers, perhaps the most ancient pedigree, largely due to the prevalence in nature of the abrasive stone, and most importantly — its hardness. Emery wheel used for millstones, almost all the time is “sharp”, unlike metal working surfaces all other grinders that have to and then sharpen. The main disadvantage of the mills Shellers— the great complexity of adjustment the working air gap L.

Rolling mills grain, acorns and similar raw materials are simple and accurate adjustment of the gap L. As a screw Shellers, profile of teeth can have a variety of shape. However, the working surfaces of rolls eventually lessen, and, if the sharpness of their edges is not restored, the peeling mill works in less economically — crushing.

In the manufacture of Shellers of this type in a home workshop one of the rollers (or even both) replace cylindrical float (see, for example, the second variant of development, published in No. 6 of the journal “modelist-Konstruktor” for 1997), and if it has a calibrated grid, the result is possible to obtain fractions a strictly specified size.

Among Shellers combined with minimal expression of the above-mentioned disadvantages are self-made design “Khadyzhensk”, make which is offered to the readers of the magazine “modelist-Konstruktor”. It is based on abrasive wheel (fixed on a horizontal shaft rotating in a single-row radial ball bearing 80204 with two shields) and set obliquely, at a distance L from it (the working gap), Drachevo file.

The feedstock is fond of spinning sand around in the space between the cylindrical surface of the sandpaper and a file L, where it is crushed to the desired fraction. The required value of L is exposed to a control node formed on the basis of bolting.

Crushing site homemade crumbler:

1 — emery wheel; 2 — strut pinch-bolt with two M8 nuts and washer Grover (4 set); 3 — mounting-adjustment bolt M8 with nut and washer Grover (5 sets.); 4 — warna the crossbar of the upper articulated — emphasis fastening and adjusting hub (3 mm sheet, St3), 5 — Drachevo file 12×38; 6 — panel (3-mm sheet, St3, 2); 7 and 8 — bottom front and rear spars; 9 — adjusting bolt M12; 10 — (2); 11 — the case of the rear bearing Assembly (steel 35); 12 — bearing 80204 (3 pieces); 13 — M14 nut with washer; 14 — the end latch; 15 is a semicircular setuplocale (aluminum or PCB, 2 PCs); 16 — shaft (steel 40); 17 — a flange (steel 35); 18 — nut M14 (left-hand thread) with a washer; 19 — 4 parallel key,5x5x25; 20 — the case of the front bearing unit (St3); 21 — radial locking of the bearing unit (2); 22 — pressure nut (steel 35); 23 — sidewall casing (2); 24 — screed-MB bolt with nut and washer Grover; 25 — M4 bolt with nut and washer Grover; 26 and 27, respectively, the front and rear spars of the upper half frames;

The power unit is single phase motor 1-1. 5 kW, torque from the shaft of which is passed to the crushing site through V-belt transmission. The size of the pulleys, adapted from scrapped automotive vehicles, based on the ratio of rotational speeds of the driving and driven shafts. Strap kotosonova, reliable, section V. In order to simplify and reduce the cost of construction adjusting its tension is… “slipping” of the power unit downwards, under the influence of its own weight, which frame performed in her slots for the mounting bolts of the motor is set at an angle of 5-15° to the horizon.

(The main materials required for the manufacture of the crumbler “Khadyzhensk”, are angle steel 40×40 mm bolts M4, M6, M8 and M10 with nuts and lock washers, and 3 mm sheet St3. The case is welded. The front and back walls are cut from 3-mm St3, and sidewalls use segments of the aforementioned area. The shaft is machined from steel 40, and bearing, as, indeed, and the clamping nut are made of steel 35.

To the front and rear walls of the housing tightening bolts are installed (followed by fixing by welding) to the side members that form the frame. In the inclined grooves of the walls of the fixed cheeks from the inside-seals insert the pre-assembled shaft unit with sand around. The bearing housings are clamped laterally by respective fastening elements, and the top — side members mounted on racks-bolts M8. Axial displacement of the shaft of the chipper exclude fixing additional stands on the rear frame spar.

Drachevo file is placed on the inclined sidewall (inside the crumbler) so that between his work painting with notches and radial surface grinding withstands the required working gap for this in the design of the grinder provides for fastening and adjusting and adjusting nodes. The flange is mounted by means of prismatic pins on the main shaft, serves to quickly install any of the pulleys, including from automotive engines.

As noted earlier, for “Khadyzhensk” in a household outlet requires a single-phase motor. Connection through an isolating transformer that provides safety in the event of insulation breakdown and other emergency situations. However, in case of necessity scarce in the village “odnofaznye” it is possible to replace a three-phase motor, including — from agricultural equipment, to develop their resources. Convinced of the health “trehfaznika”, it is connected to a household power on the circuit with phase-shifting capacitors, the features of which have been repeatedly described in the journal “modelist-Konstruktor” (see, for example, publications in № 11’90, 12’92, 8’95 and 8’99).

Design “Khadyzhensk” (as its original version presented in the photo) reliable, efficient n simple:

1 — tub bracket; 2— top rails; 3 — emery wheel; 4, a semicircular cheek-sealer (2 PCs); 5 — flange; 6,13 — mounting-adjustment bolts; 7 — file; 8 — body; 9 V drive belt; 10 — a drive pulley; 11 — single-phase motor (220 V, 1 – 1.5 kW); 12 bottom rails; 14 — the driven pulley; 15 and 16 the front and rear bearing units; 17 shaft;

Up the electric crumbler also includes magnetic starter, current relays, repair switch with visible break the chain… in short, it is desirable to have everything to work on this chopper was completely safe.

Easy to manufacture, kruporushka “Khadyzhensk” is simple and its maintenance. Replacement of emery stone, for example, is performed in the following simple sequence.

First of all, the maximum weaken of the adjustment, fastening and adjusting bolts and remove from the structure file. Unscrewing the bottom nut on the tie racks-bolts M8, remove the top semi-frame. Then pulled out of the walls of the housing in the direction of the eyes (of course, removing this nut M12 located at the rear) practically have not disassembled the shaft Assembly of the chipper. Remove the rear bearing Assembly, Unscrew the clamping nut and replace the abrasive wheel. Build updated crumbler is performed in the reverse sequence.

In fact, the duration of life “Khadyzhensk”, that is, not refuse. The fairness of such approval will be able to see everyone, he fashioned himself as reliable, a good kruporushka — benefit, effort and funds it would require quite a bit.

Vladimir ZORIN, the town of Khadyzhensk, Krasnodar Krai

Recommend to read FUSE-“PHOENIX” Overcurrent, short circuit for power supply... To protect against this scourge in the apparatus used old world as the means of fuses. Some are mounted in a special cartridge-holders,... BIKE Morning gymnastics, running, lignite winter and summer Hiking trips, Cycling is an effective means of health promotion. However, the bike largely depends on St of road traffic, the...

Scroll back to top

Have in the farm or on a personal farmstead of a good high-performance kruporushka not a fad, but rather a vital necessity. Especially when you consider the high cost of ready to “purchase” animal feed and often inconsistent quality of the advertised. However, some specific designs of existing diversity of shredders (including home-made developments, published at different times in the journal “modelist-Konstruktor”) to choose?

Have in the farm or on a personal farmstead of a good high-performance kruporushka not a fad, but rather a vital necessity. Especially when you consider the high cost of ready to “purchase” animal feed and often inconsistent quality of the advertised. However, some specific designs of existing diversity of shredders (including home-made developments, published at different times in the journal “modelist-Konstruktor”) to choose?