Often in business-industrial practice there is a need to transfer thick (and not) liquids from containers of large volume, for example—from the barrel. It’s not necessary to have a special pump, especially in the workshop of homebrew: master himself can assemble from readily available materials simple device, suggested by doctor of technical Sciences V. Artemyev.

Often in business-industrial practice there is a need to transfer thick (and not) liquids from containers of large volume, for example—from the barrel. It’s not necessary to have a special pump, especially in the workshop of homebrew: master himself can assemble from readily available materials simple device, suggested by doctor of technical Sciences V. Artemyev.

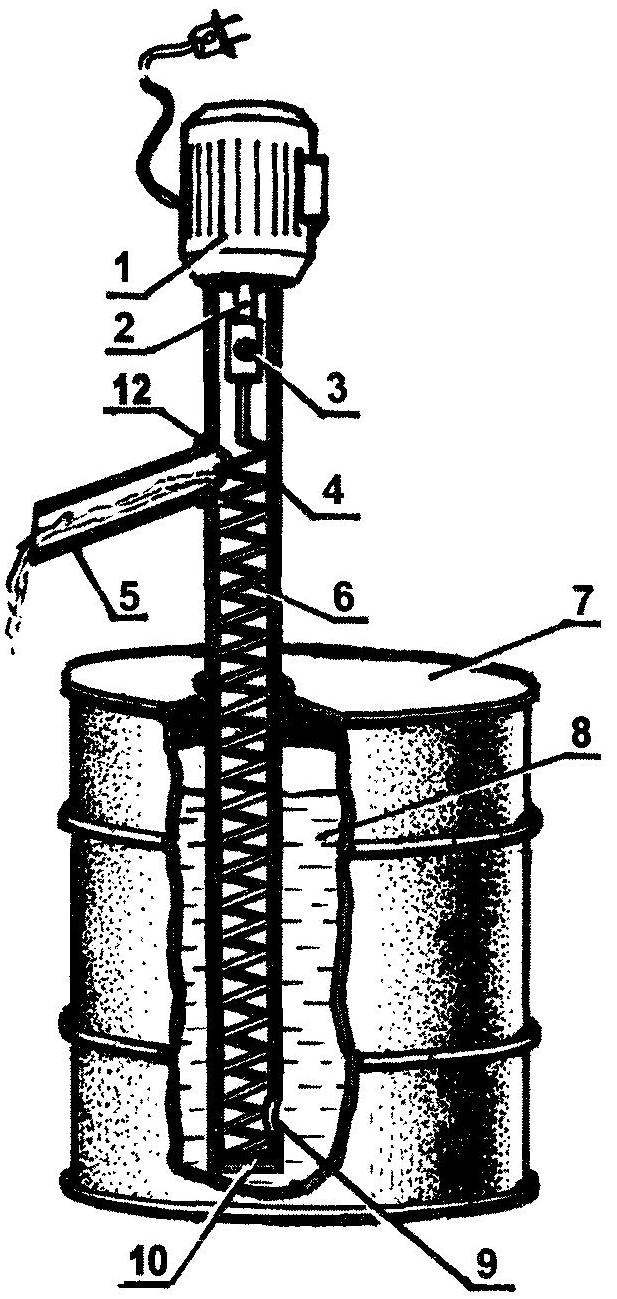

Improvised pumping device consists of three main components: a small motor with power 0.37 kW, powered by a regular wall socket: plastic or metal pipe-casing and a spiral spring. How is interact named to force the liquid from the container to rise and flow into another container?

The originality of the device lies in the fact that the main role here is played by… the spring. It is connected to the motor shaft and enclosed in a tube, in which rotating their turns, like a screw, entrains the liquid and raises it up.

Spring pump:

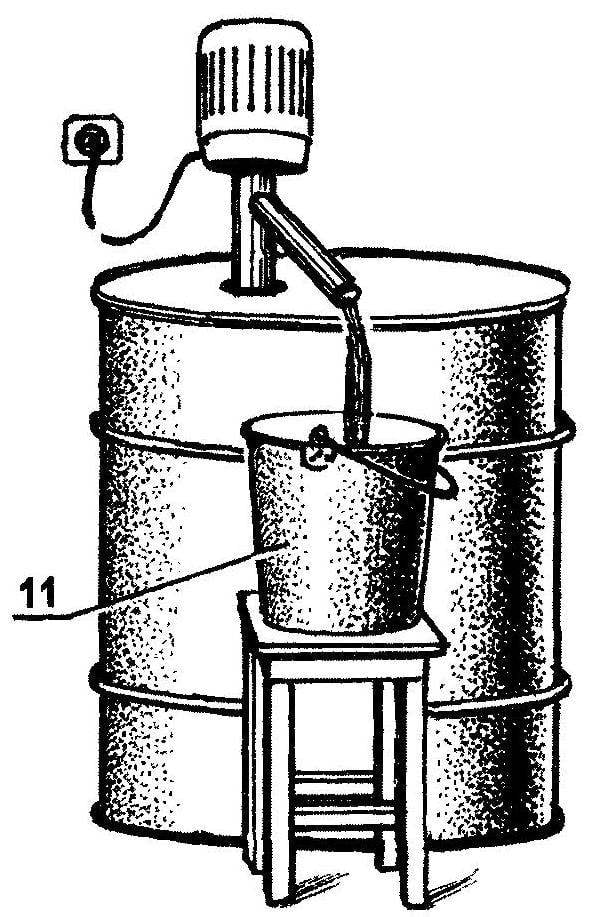

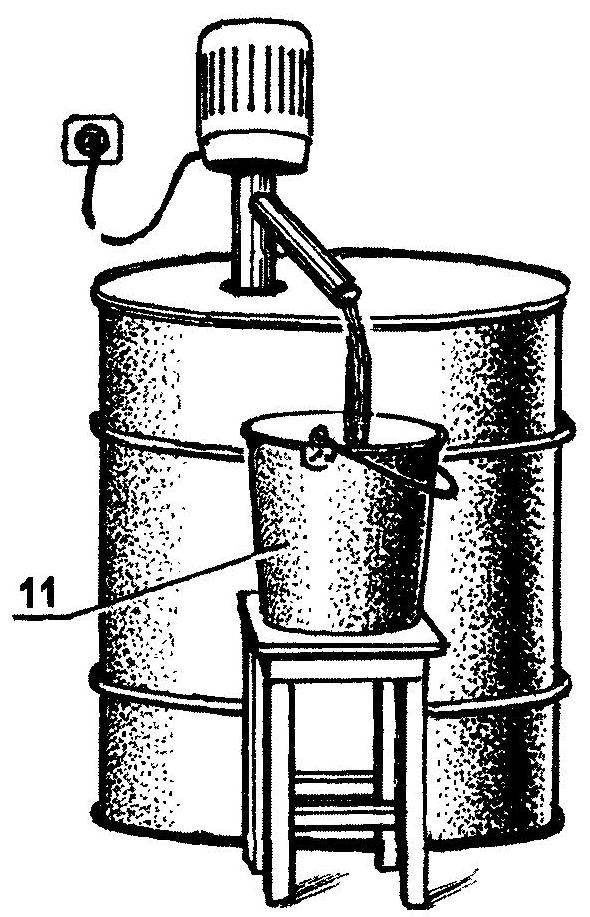

1—motor; 2—motor; 3—transition coupling; 4—the tubular casing; 5—unloading branch pipe; 6—spring; 7—containers; 8—viscous liquid; 9—suction port; 10—plug casing; 11 —reception capacity; 12—unloading window

To work effectively enough to the diameter and pitch of the spring was about 30 mm, and the diameter of the tubular casing — 35 mm. If there are no suitable springs, it is possible navit wire St.65G with a diameter of 4 mm. to the motor shaft spring is connected by means of threaded sleeve or adapter coupling.

Bonnets—plastic pipe with a length of almost five feet. At the bottom it has a suction port, and closer to the top, unloading the box and welded thereto is tilted down a drain pipe.

At speed of about 1400 rpm spring in the pump can pump out almost 400 kg of oily liquid within one hour.