Because of the variety of sprayers are the most promising for farmers, owners of allotments are, in my opinion, disc. The main advantages of these sprayers is that the spray fluid obtained monodisperse (i.e., having predominantly the same diameter) drops into an easily regulated and scientifically sound ranges from 50-100 microns (when spraying) to 3-4 mm (for sprinkling). The flow of the working fluid is optimal. In particular, the portable disk sprayers (PDO) it usually does not exceed 2.5 liters per hectare of cultivated area. Width of 0,7—1,5 m, depending on the fluid flow, the speed of rotation of the motor shaft and therefore resourceful drive itself.

The surface concentration of the droplets on the plants throughout turns out very close to the optimum (small values of its proper effect is not given, and large threat to plants). Loss of chemicals during spraying PDO minor. But they can be reduced by proper selection of the fractional composition of the aerosol. According to the scientists and practices from izmelchennost-year-depend on the degree and uniformity of deposition, the evaporation speed and with drops on the treated plants, as well as the intensity of the penetration of the drug into tissues.

Using disk sprayers and no less famous for their counterparts, also have to consider that with decreasing droplet size, the processing efficiency is improved. However, increasing dispersivity increases the susceptibility of the microparticles to the wind drift.

Adjustable storage node, transport n economical expenditure of the working fluid

Alkaline battery 10НКГЦ-3,5-1 with a homemade block of the electronic controller as a power supply voltage to 12 V, load current up to 0.4 A

Note: the motors listed in the table have been tested and in working with low voltage (12-volt battery). They bury keep high revs, but with high current consumption (0.4 A full load).

Choosing one or the other mode spraying, it is impossible not to take into account that droplets with a diameter of about 80 µm is often evaporate before reaching the workpiece, and 30 micron in the daytime generally do not settle because of atmospheric diffusion, but easily spread through the air outside the treated field. In addition, with the increase in dispersion of the aerosol easily penetrate into the respiratory tract, it becomes very dangerous for staff.

Optimal for PDO should be considered a regime, when the diameter of droplets when spraying is kept in the range of 100-350 microns, and the best — when the droplet diameter of 150 µm. The working fluid was readily available and nonvolatile to significantly reduce the evaporation of the aerosol in the process of deposition and to achieve maximum possible penetration of the drug into the tissues of plants.

Engines for portable disk sprayers it is desirable to take the electricity running on a constant current in the voltage range considered safe for humans. In designs homemade PDO, for example, electric motors work great DSR-14, DSR-22 and PDM-35. They are economical, compact, developing, with 27-volt power shaft rotation speed in the range of 3500-4800 rpm. of Course, it is not forbidden and the use of other DC motors designed for voltages up to 27 V and the rotation speed up to 10,000 Rev/min. However, in any case, the connection to the power source through the voltage regulator.

NOTE: TO ENSURE ELECTRICAL SAFETY IT IS PROHIBITED TO USE 220-VOLT ELECTRIC MOTORS IN CONSTRUCTIONS OF THE DISK SPRAYERS!

Main self-made part in my proposed design is a disc atomizer, for the sake of brevity in the future — ROM. It is machined from aluminum as a sufficiently strong, light and corrosion resistant material, the surface of which has a good wettability maslorobnij substances. The latter is particularly important for the effective work of the whole body. Dural to such an important detail had also increased wettability by water and aqueous solutions, it is required to etch: 60-70% solution of caustic soda, and then in 35% nitric acid. Only after that the disk can be mounted on the motor shaft (e.g. with locking screw).

Of other structural materials for the disc are quite reasonable, for example, plastic “vinizol” that work well in water and mineral-oil environments. It is also possible to use dispensers of ebonite, Perspex, PTFE. The main thing that made the drive should have an easily wetted surface and be durable enough to supply working fluid in a continuous stream of and as close as possible to the axis of rotation (constant speed, no vibration) was provided and the aerosol spray of desired fineness.

The housing that protects the disk atomizer from mechanical damage, comprises two side walls (200-mm plastic plates), bonded to each other by four struts with bolts, and a metal glass-holder. The latter is rigidly fixed on the rod of 15-25 mm duralumin or fiberglass pipe (perfectly acceptable and ski pole with a handle).

Vinyl tube with clip, a regulator, a tap and a filter cleaning fluid is a medical drip (transfusion of blood, blood substitutes and infusion solutions). Mount to the bar — the place transparent tape.

A bottle of fluid nearby, in the reference frame, which is the best suited, “holder”bandage for soft milk jugs. Forked this pen, sold in stores household device performs the functions of the bracket for secure attachment named node on the rod body.

As power source it is recommended that the 24 V battery of electrochemical cells that can be replaced with two alkaline (10НКГЦ-3,5-1 or 10НКГЦ-6,0-1) or acidic (ZMT-ZMT or 9-14) battery from the motorcycle, designed for a total voltage of 24 V.

Electronic voltage regulator, used for supplying power to the electric motor, executed according to the design published in the journal “modelist-Konstruktor” No. 12’2002. Acceptable also and analogues with output parameters 0-24 V at currents up to 1.5 A.

The voltage regulator preferably placed directly on the power source, for carrying which you want to provide a belt hanger. Connection with a module — DC motor with a disk atomizer in a protective casing with the aid of the cord, missed, and the vinyl tube with the transported fluid, through the cavity of the rod and the hole in the wall of the glass bracket.

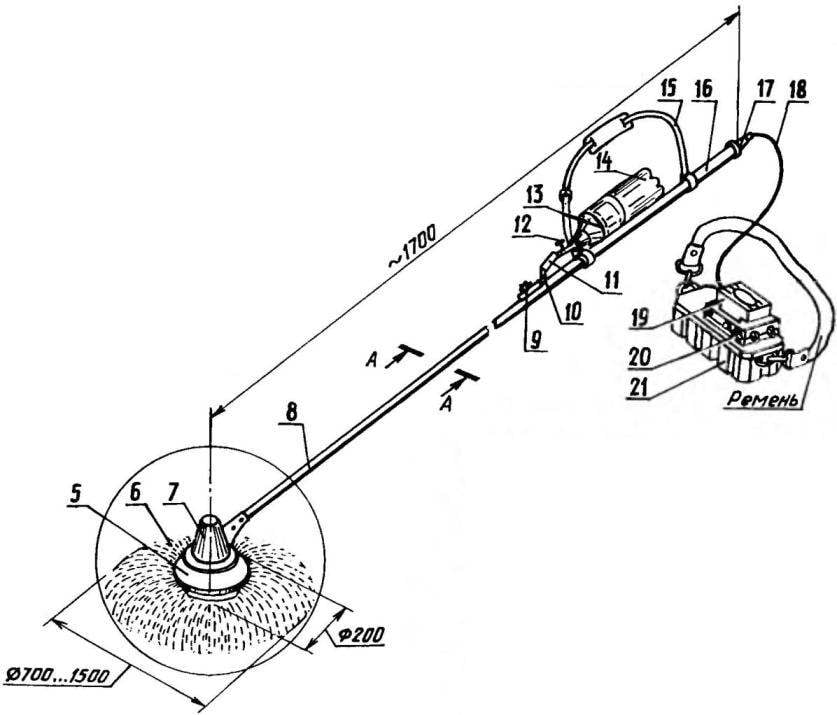

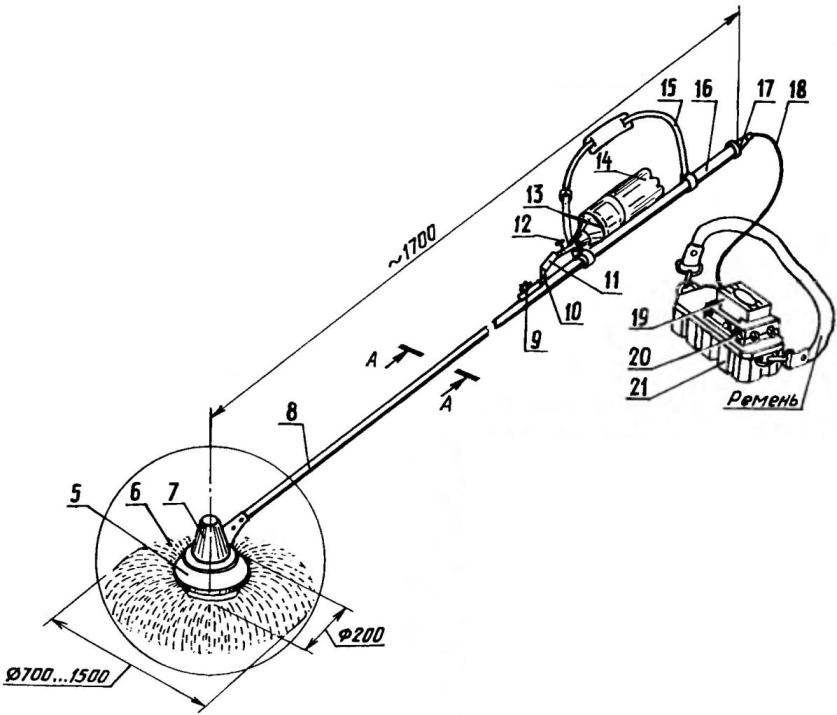

Schematic and design a homemade disc sprayer:

1 —DC motor (27, up to 6 W 3500-4500 rpm); 2 — screw M3; 3 — disc nozzle (aluminum); 4 — spacer (hairpin with six M3 nuts and bushing limiter, 4 sets.); 5 — the sides of the body (plastic plate d200); 6—dispersed spray; 7 — a metal Cup-bracket; 8— rod; 9 — clamp flow regulator of the working fluid; 10—vinyl tube; 11 — filter; 12 — tap; 13 —reference frame; 14 — a plastic bottle with the fluid; 15 — shoulder strap; 16 — an arm; 17 — rubber tube-absorber; 18 — the cord; 19 — voltage regulator; 20 — the switch; 21 — power source (battery of electrochemical cells or batteries, up to 24 V At 0.4 A); items 9-12 — ready, from the medicine dropper

Now a few additional recommendations associated with the operational module. For cost-conscious approach to the solution of economic problems it can be successfully used also in the role of a humidifier in the greenhouse or, after increasing the diameter of the holes on the perimeter of the disk, such as compact sprinkler system. As promising application module for disinsection, disinfection of premises, and upon receipt and effective use of the spray of medicines in livestock farms and poultry houses.

Even more can be expected by installing the modular unit for automatically moving the platform in reverse and vertical lift. I am convinced that this modernization will allow agricultural work related to the spraying, sprinkling, wetting, and handling of plants and soil, any chemicals, in the category of less time-consuming, taking place without the presence of the operator in the danger zone.

The owner of the modern greenhouse or even a small garden plot enough, apparently, to get one or two such modular units. Large-scale farmers, of course, this is not limited. It is possible that he will have to take care not only about the installation of multiple modular units on a tractor trailer rod, the improvement of the working fluid, its automatic shutdown, but also the more powerful the power source of the engines a constant regulated current.

A. NORVATOV, In o l s s K

Recommend to read ORBITA STUDENTS The Moscow Lenin order aviation Institute named after Sergo Ordzhonikidze at the faculty of aircraft engines has a student design Bureau (SKB-2), which is headed by candidate of... DRILLS VIDEO Do you know. the drill bit in cutting the hole in the glass can be done in just half an hour. It will be based on the movie glass cutter fixed in the slot on the end of the steel rod....

For chemical protection of agricultural crops from pests and diseases, and in making micronutrients during weeding chemicals are usually converted into coarse aerosol, which is directed to plants or soil. At the same time seeking to labor costs were minimal, and spraying the preparations were used, if possible, without losses. And fractional composition of the droplets, the content of active substances try to make optimal.

For chemical protection of agricultural crops from pests and diseases, and in making micronutrients during weeding chemicals are usually converted into coarse aerosol, which is directed to plants or soil. At the same time seeking to labor costs were minimal, and spraying the preparations were used, if possible, without losses. And fractional composition of the droplets, the content of active substances try to make optimal.