The electric winch is arranged as follows. In the upper part of the welded corner of the frame, the housings of the ball bearings is the shank of a drive on which is rigidly mounted the sprocket from the motor scooter “Vyatka”. Below is the drum, made of steel pipe with a diameter of 152 mm on both sides to the drum welded steel cheeks. The center hole machined a steel bushing which is pressed a brass sleeve bearings. On one of the cheeks of the drum is fixed a tooth for engagement with a similar element located next to the sprocket z2=60.

At the ends of the drum shaft mounted in corresponding enclosures of bearings 304. And the shells themselves have two holes for attachment: one in the form of a groove, which regulates the tension of the chain, the other with a diameter of 8.2 mm.

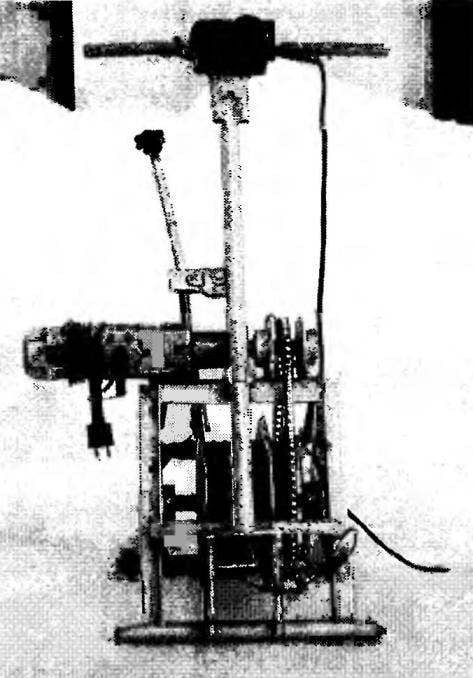

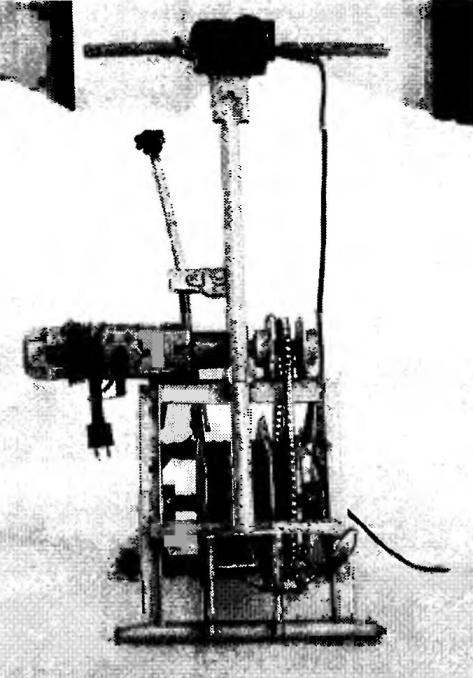

The layout of the tow plow:

1 — reel tow cable, 2 — arc pickup, a 3 — circuit PR-12,7, 4 — bearing housing drive shaft (2 PCs), 5 — node mounting the control Cabinet (rod automotive compressor), 6 — front control (steel pipe 30×2), 7 — a mechanism for connecting the drum 8 — electric drill (600 watts, 250 rpm), 9 — roller clamp (brass pipe 11×2,5, 2 PCs), 10 — electrical junction box with socket, 11 — bracket Crescent (STZ, 2 PCs.), 12 — spring anchor, 13 — anchor Assembly 14 — frame steel (welded construction area 32×32, pipe 32×2,3 and the sheet s2), 15 — crossbar (STZ), 16 —axle-stud M10 (2 PCs), 17 — M10 nut (8 PCs.).

The driveshaft Assembly:

1 — shaft (Ст6), 2 — bearing housing drive shaft (STZ, 2), 3 — bracket Crescent (STZ, 2 PCs.), 4 — sealing washer (STZ, 2), 5 — sprocket z1=22, 6 — bearing 304 (2), 7 — spar frame, 8 — bolt M8 (4 PCs).

Node output shaft Assembly:

1 — sprocket z2=60, 2 — teeth clutch (steel 45), 3 — sleeve-liner (brass pipe 34×3, 2 PCs.), 4 — drum (steel pipe 152×4), 5 — shaft driven (Ст6), 6 — cheek drum (STZ. 2), 7 — the drum hub (STZ, 2 PCs.), 8 sealing washer (STZ, 2), 9 — bearing housing driven shaft (STZ, 2), 10 — bolt M8 (4 PCs), 11 — solitaire frame (STZ, 2 PCs.), 12 — 304 bearing(2 PCs.)

The connection mechanism of the drum:

1 — drum, 2 — a plug of the lever of switching, 3 — axis lever, 4 — spar frame, 5 — a stopper extreme positions of the lever (2 PCs.), 6 — bracket lock, 7 — lever handle switch, 8 — stopper, 9—washer, 10-pin, 11 —tooth clutch, 12 — spring.

Attachment of rope to drum.

Power supply connection:

1 — power cable twisted pair, 2 — box elektrorazpredelenie, 3 — socket plug, 4 — plug cord with plug drills, 5 — front control, 6 — the switch of TV 1, 7 — arm (2 PCs.)

Diagram of the mechanism chain tension:

1 —bearing housing drive shaft, 2 — bracket Crescent, 3 — circuit PR-12,7, 4 — star, z2=60, 5 — bearing housing driven shaft, 6 — frame, 7 —sprocket z1 =22, 8 — groove adjustment.

Docking drill with the drive shaft:

1 — drill (auxiliary arm is conventionally not shown), 2 — the shank of the drive shaft 3 is a bracket-eye, 4 — bolt hollow.

The drum moves freely along the axis of the brass bearings. On the frame of the winch (on its axis), there is a lever with fork, which includes one of the flanges of the drum.

To return the plow to the beginning grooves of the drum is discharged to the lever out of engagement with the sprocket, and the wire unwinds freely. Then the drum was once again introduced into engagement with the sprocket, includes winch and plow makes stroke of the plow.

On the axis of the shift lever is set braking device. It serves to reduce the rotational inertia of the drum when unwinding the cable. As practice shows, the need for it arises as soon as the stroke of the plow is shorter than the cable installed on the drum. On the winch, had initially similar devices, the cable is often confused, sometimes, even came with a drum and threatened to become entangled on the shaft that would lead to the release of the latest failure.

Braking device works perfectly and has not, as it turned out, a significant resistance to return of the plow on.

In the manufacture of the leads of the cable, I decided to abandon the use of bearings and chose a more simple scheme. The gist of it is that two axles with a diameter of 10 mm installed tube-brass runners. To reduce the friction on the axis caused the grease. And now, as they say, goryushko don’t know.

He was convinced when processing land plow, mouldboard my winch with a fairly modest power plant (600 watts, 250 rpm) shows better results than the serial tillers of the type “Beam”, “Neva”. And services a homemade electric Plowman easier, more convenient, more reliable, than a powerful factory metopomancy. For example, to adjust chain tension enough loosening 4 bolts, be slightly offset (up-down guiding groove) both the bearing housings output shaft and re-tightened to tighten the aforementioned bolt connection.

Now a few words about the plow-self-propelled. I have used a variant similar in many ways to analogue, published in the “Modeller-designer”, No. 6’90. I note one detail: the blade of my plough is made of stainless steel. Suggest others, if possible, go to the “stainless steel” — costs will pay off handsomely. There are, I think, is the point to experiment with the design of a plow, to compare with other, published, say, in № 4’94, 2’95, 8’95 log.

And again. In any case, we should not neglect the safety rules. With electricity trifled with, but the winch is on the network with the voltage 220 V, no isolation transformer and equipment electronic security! To use this technique in the ploughing, observing extreme caution. To avoid damp rainy weather, and in dry to proceed with the work only taking care of personal protection from electric shock — rubber footwear and rubber gloves.

ALEXANDER V.

The Ivanovo region.

Recommend to read THE “MACHINE” OF THE SLIDER This simple device will help the baby to take its first steps. We are talking about the well-known "Walker", however in the store they often will not find. So I decided to take up the... ALL-TERRAIN VEHICLE WITH ENHANCED… COMFORT For residents of the Urals, Siberia, the North, and the Far East (that is, most of the country's territory), the need for a vehicle like an all-terrain vehicle is simply a vital necessity....  Having a pretty powerful compact drive, the electric long gone among the leaders of household tools. And with the attachments, all kinds of fixtures are not averse and in agricultural work to become a foremost: already mows, threshes, and other operations performs excellently. The universal becomes! Moreover, with the light hand of the inhabitant of Leningrad region Vladimir Morozov drill successfully “mastering” even the arable business, as regularly informs readers “modelist-Konstruktor”.

Having a pretty powerful compact drive, the electric long gone among the leaders of household tools. And with the attachments, all kinds of fixtures are not averse and in agricultural work to become a foremost: already mows, threshes, and other operations performs excellently. The universal becomes! Moreover, with the light hand of the inhabitant of Leningrad region Vladimir Morozov drill successfully “mastering” even the arable business, as regularly informs readers “modelist-Konstruktor”.