In order to stabilize the generator voltage (and it should be stable for any load change) in the supply circuit of the winding introduced by the relay-regulator, made on the basis of common РР362Б. But as a serial device designed for connection to a 14 In, and work it is now necessary when other, much larger par, then had to adjust the schema to include in series with the relay coil K2 “damping” resistor Я7 type MLT-0.5 resistance 25 Ω (Fig. 2). Working the currents and voltages at the test points could be maintained at the level of the acceptable values, which ensured high reliability of the whole frequency Converter.

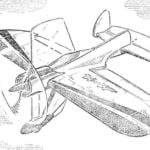

Fig. 2. Kinematics and electrical diagram of the power Converter to supply three-phase motor shearing machines or other devices (200 Hz, 36 V, 100 W, 12, OOO rpm) from domestic single-phase network:

I — ballast type (magnetic starter with svetosistem “Network” and “Work”); II — the engine of the electric drive (50 Hz, 220 V, 500 W, 2850 rpm; single or three phase, the latter is necessary for the phase-shifting capacitors); III — V-belt drive (1 = 1,38); IV — improved generator Г273А; V — a modified relay-regulatory-tor РР362Б;

1 — the winding coils of the stator 2 — stator; 3 — rotor; 4 — field winding; 5 — brush (2 PCs.), 6 — pin ring (2); 7 — detachable diode reverse polarity (3 pieces); 8 — yoke; 9 — spring; 10 — thermobimetallic plate; 11 — core; 12 — anchors

As before the modification, the modified РР362Б contains a voltage regulator PH (Fig. 2 with continuous numbering of components and nodes is — K2) and protection relay RZ (K1), the transistor /T 1, which is located on the heat sink, two semiconductor diode (locking — /07 and the dampening—VD8), and resistors: base — R1, accelerating — R2, additional — RZ, temperature compensation — R4, seasonal adjustment, “Summer”-“Winter” — R5, feedback — R6. Moreover, PH and PS are placed on the panel in the seal compartment of the device, all the resistors under the dash, and the transistor — diodes in a ventilated compartment. The air for cooling passes through the slit in the cover.

Electromagnetic vibrating PH — sensitive element, responsive to the generator voltage rise. The contacts of the controller open or close the transistor VT 1, which conducts or does not conduct current in the excitation winding of the mating Г273А. Is the PH of the yoke core with the winding, anchor with spring and thermobimetallic plate, normally closed K2.1 and the normally open K2.2 contacts. The protection relay is, in fact, has a similar structure. Perhaps, the only difference here is the number of working contacts. They have a RZ one pair (K1.1).

Winding PH and RZ contain at 1224 loop of wire PETV-0,27. The resistance of each DC

Of 17.1 Ohms. The gap between the contacts of the voltage regulator should be 0.2—0.3 mm. the relay protection this parameter from 0.7 to 0.8 mm. the adjustment is made by moving the holder contacts and the restraining anchor.

To drive the generator of the 500 W single phase motor. Failing this, you can use the more common three phase motor a little more power. To work in a household electrical outlet it is connected with the starting and working condensers (see “modelist-Konstruktor” № 2’86, 11’90, 12’91, 8’99).

The size of the pulley to obtain the desired 200 Hz from the above generator, the rotor of which (relative to the motor shaft) is driven according to precise proportions:

(n1/n2)=(D2/D1); where n1 is the frequency of rotation of the rotor of the electric motor, rpm; n2— rotational speed of the generator rotor, rpm; D1 — diameter of motor pulley, mm; D2 —diameter of the generator pulley, mm.

In particular, if nominal D2 = 105 mm, n2 – 2000 rpm and n1= 2850 rpm D1 is the leading should be 74 mm. Drive belt it is better to take a wedge (for example, from the washing machine).

As rigid bases for Assembly of the entire kinematics is desirable to use a box frame of steel angle 25×25 mm dimensions, and other parameters of such a unit largely depends on the engine.

The enclosure must be closed, to prevent accidental touching V-belt transmission and current-carrying parts of the structure. Wall mesh, for better ventilation of the Converter. A cover is executed of solid insulating material (e.g., PCB thickness 3 mm), serves as both a switchboard with located on it the ballast device type magnetic starter, three-phase ashema “Load”, shotokutaishi “Network” and “Work.”

To extinguish all types of vibrations, the transducer should be mounted on small rubber shock absorbers and electrical safety — also securely grounded.

A. ROGOZHIN, S. Krasnokumskoye, Stavropol Krai

Recommend to read

ELECTROMILITARY

ELECTROMILITARY

It is not easy to be "protanium"! As in any other class of modeling, the success of his performance depends on the number of workouts. And how to look forward to the end of the long... “PIRATE”IS A LOSER

“PIRATE”IS A LOSER

Fighter VOUGHT F6U PIRAT. The appearance at the end of the war, military jet aircraft in Germany and Japan forced the command of the naval forces of the United States to start a program...