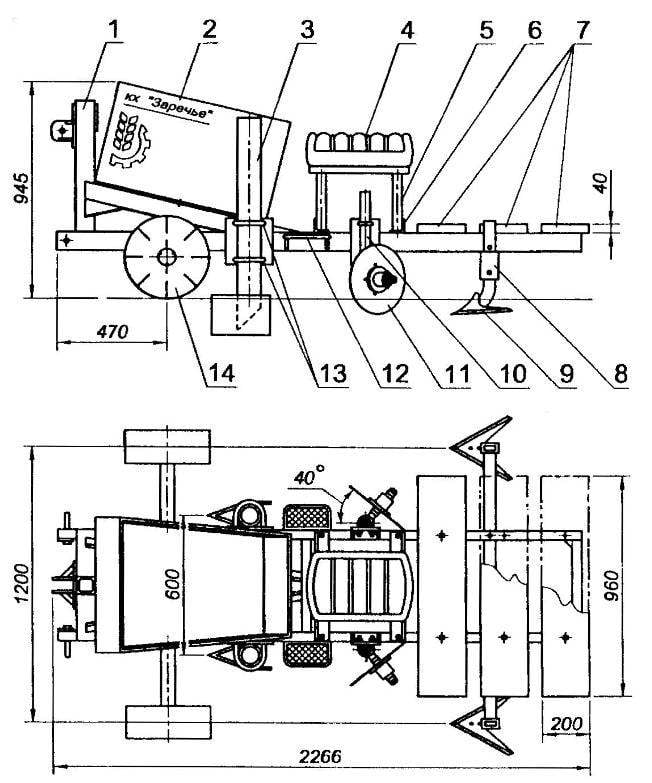

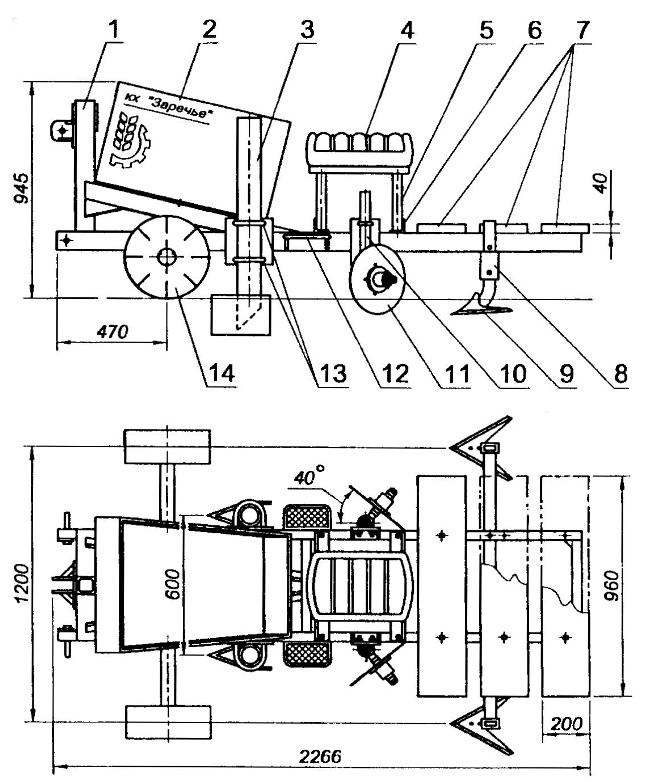

In addition, to the side members secured support of podselenie of angle 50x50x5 mm and footboard of 6-mm steel sheet, whose location on the frame were determined depending on the growth of the sower. For its growth were selected and the height of the legs of podselenie, so their sizes are not given. The seat itself is made of angle 50x50x5 mm (frame), boards (bottom) and foam rubber, covered with leather (cushion).

To the inclined braces welded a plate bracket to which two bolts M10 is attached to the hopper of the planting material (potato tubers) with a volume of 0.17 cubic meters, the Bunker is made of sheets of plywood 12 mm thick, coated with linseed oil, and then water-resistant paint.

From the bottom to the frame by bolts attached to the wheel axle and a holder of rippers.

Wheel axle team. At the heart of it — a thick-walled tube, the ends of which are inserted machined on a lathe axle, or spikes. The steel spikes hold the steel pins that are pressed into the radial holes drilled after Assembly. Head pins welded.

The wheels are welded from several sheet metal parts. Their production is quite a laborious process, but it is justified by the fact that a cylindrical surface of the wheel is less soil compaction. However, it is possible to use a suitable rubber wheel from farm machinery.

Wheel axle:

1 — wheel (sheet s4,2); 2 — spar frame potato planter; 3 — axis (pipe 60×8, L1067); 4 — clamp (sheet s8. 2); 5 — bolt M16 (4 piece); 6 — screw М5х0,5 (6 PCs); 7 — hub cap (2); 8 — nut M16 (2); 9 — split washer (2 PCs); 10 — the bearing washer (2 PCs.); 11 — 205 bearing (4 PCs); 12 — hub (2 PCs); 13 — spacer (tube 30×2,5, L55,2); 14 — gasket (felt, 2); 15 — pin (6 pieces); 16 — spike (2 PCs)

Wheels are welded to the hub, each of which rotates on two bearings 205, impaled on spikes. Pollution bearings are protected with covers and felt pads.

The frame of the potato axis is attached with four bolts M16 by means of two clamps made of sheet steel.

Holder of rippers, on the contrary, is quite simple. This is a rod with clips on the ends, which are inserted in a rack of a cul-tivating feet. Square rod welded from two pieces of angle 50x50x5 mm (obtained profile is much better resists twisting — their main workload than normal “square”, although the latter is smarter), and clips from pieces of sheet steel with a thickness of 6 mm. the dimensions of the clips are chosen so that stands of hoes were in them with millimeter clearances.

Did not require special material and labor costs and you severely. Each of them consists of the VAS deferens — tubes with a diameter of 100 mm, bottom which is welded to borosport from 6 mm sheet steel. The thickness of the tube wall is 3 mm (not less thin will bend under the pressure of the resisting soil). The degree of penetration of borosport weakened step ladders is regulated by the vertical movement of the hoses along their supports on the frame. Ladder after adjustment, tighten very firmly, otherwise the seed will unfold around its axis — load on borosport significant.

The sealing disks taken out of the planter WITH at 4.2. They required a slight alteration, because they have only one bearing 203. I bored through the hub of each disk to the required size and pressed to her body, are designed to have two bearings 160503. New bearings have the same housing size as the old one (except a little wider), but closed with one hand seal, so they are preferred. Installing bearings seals out, got a site, completely isolated from dirt and dust.

This planter is a pretty solid car. Mini-tractor with the engine from, say, scooter “Ant” and weighing 300-500 kg, she is probably “too hard”. But the truck is bigger and more powerful — quite on forces. For example, my mini-tractor is equipped with an engine UD-2, together with the driver, ballast loads on the rear wheels and front counterweight weighs about 850 kg, and it operates in conjunction with a planter without any effort. A counterweight is needed in order during lifting of the planters tractor stability, not bullied “nose”. Without counterbalances this happened.

The work is heavy, but grateful. And to make it easier, productive and interesting. Only need not hesitate to undertake the manufacture of various mechanical assistants. Since there are tools, appropriate materials, time and, most importantly, interest in the case — will succeed. If not first time then certainly the second — for sure!

G. LEGOSTAEV, farmer, S. M and W to n o, Bashkortostan

Recommend to read

GARAGE FOR MOTORCYCLE

GARAGE FOR MOTORCYCLE

A good host never gave up his horse under the open sky: proskakal, carefully covered him, flushed, with a blanket, fed-fed and wound up in the stables to rest. The same respect is... DISCRETE CUTTER

DISCRETE CUTTER

Who ever cut on a lathe a series of identical parts of complex shape, he knows how difficult it is to do the same in their configuration. In the secondary school № 2 of Donetsk city...

Many farmers dream of a mini-tractor. It can be purchased in the store or do it yourself. But the benefits of a mechanical assistant would only be the case if it comes with tools that allow to mechanize agricultural work. One of such tools — a homemade trailed two-row potato-planter, which will be discussed.

Many farmers dream of a mini-tractor. It can be purchased in the store or do it yourself. But the benefits of a mechanical assistant would only be the case if it comes with tools that allow to mechanize agricultural work. One of such tools — a homemade trailed two-row potato-planter, which will be discussed.