To trim and shape one or two bushes in your front garden, to shorten a rapidly grown whip that appeared out of nowhere right in front of the window during the summer, you can use ordinary garden shears. As they say, snip — and it’s gone. Well, what if the volume of “hairdressing” work is immeasurably greater? If, say, you’ve decided to shape your shrub so as to get sculptural compositions from the green plantings: bright ones that give a unique appearance to your entire estate? Then you’ll need a different, mechanized tool instead of shears and pruners.

Getting such a tool during a period of general shortage is a problem. And it’s expensive: the tool itself will cost a pretty penny, as they say, and the work is seasonal.

A long-time subscriber to our magazine, A. Khikmatov, a graduate student at Tashkent State Technical University, solved the problems related to shrub shaping in his own way by crafting an original hedge trimmer attachment for the widely used hand tool — an electric drill.

Quite a few hand tools for mechanized trimming of bushes and other green plantings have been developed. Including by amateur craftsmen (see, for example, the publication “M-K” No. 6 for 1985 about the universal electric mower EKU-1). But in all the designs I’ve encountered, the motors are their own, built-in, which, of course, cannot but affect the cost of the hand tool itself.

In my proposed design, there is no built-in motor. Essentially, it’s just a highly efficient attachment for an electric drill that practically every homeowner has in every house.

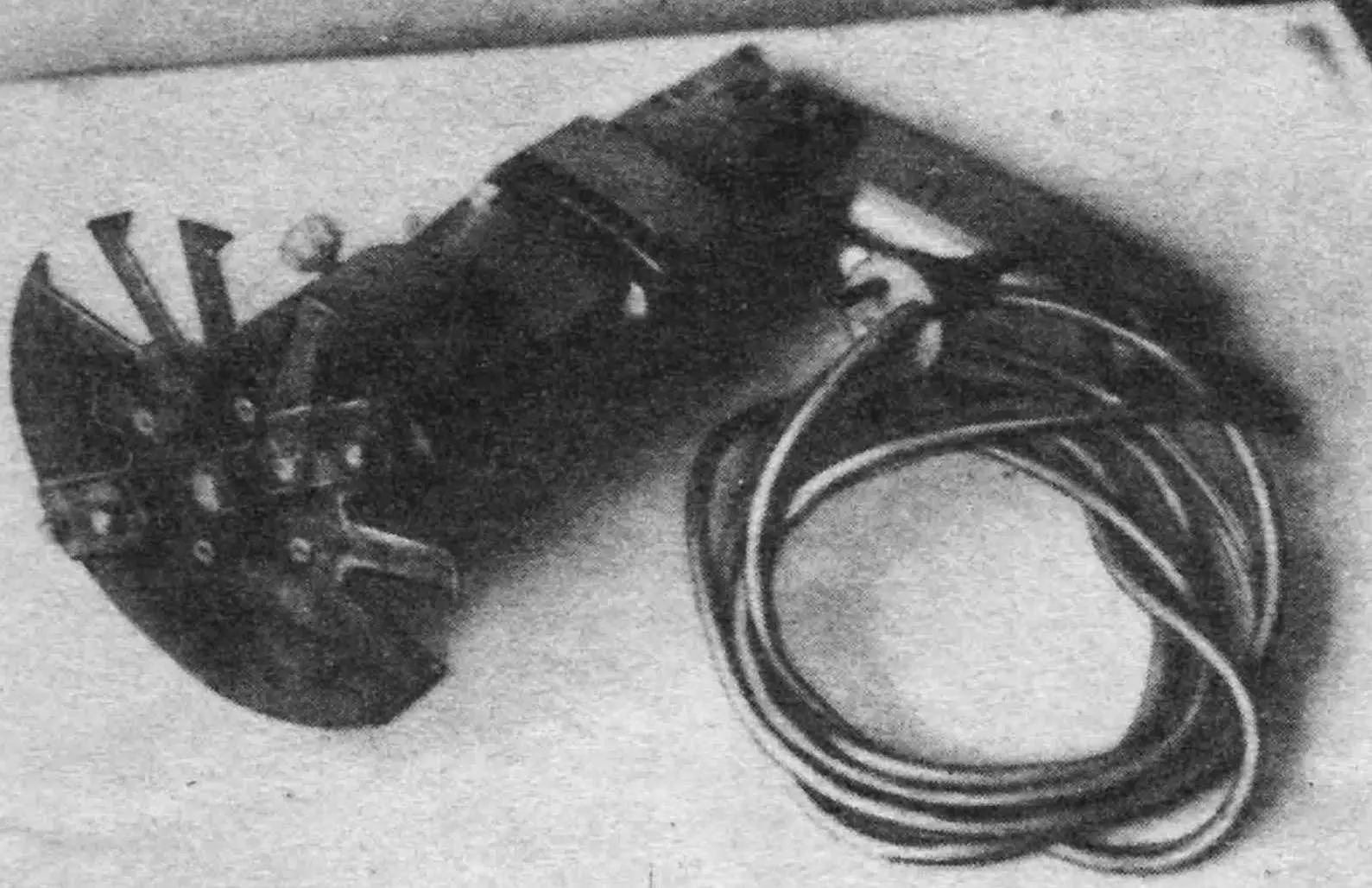

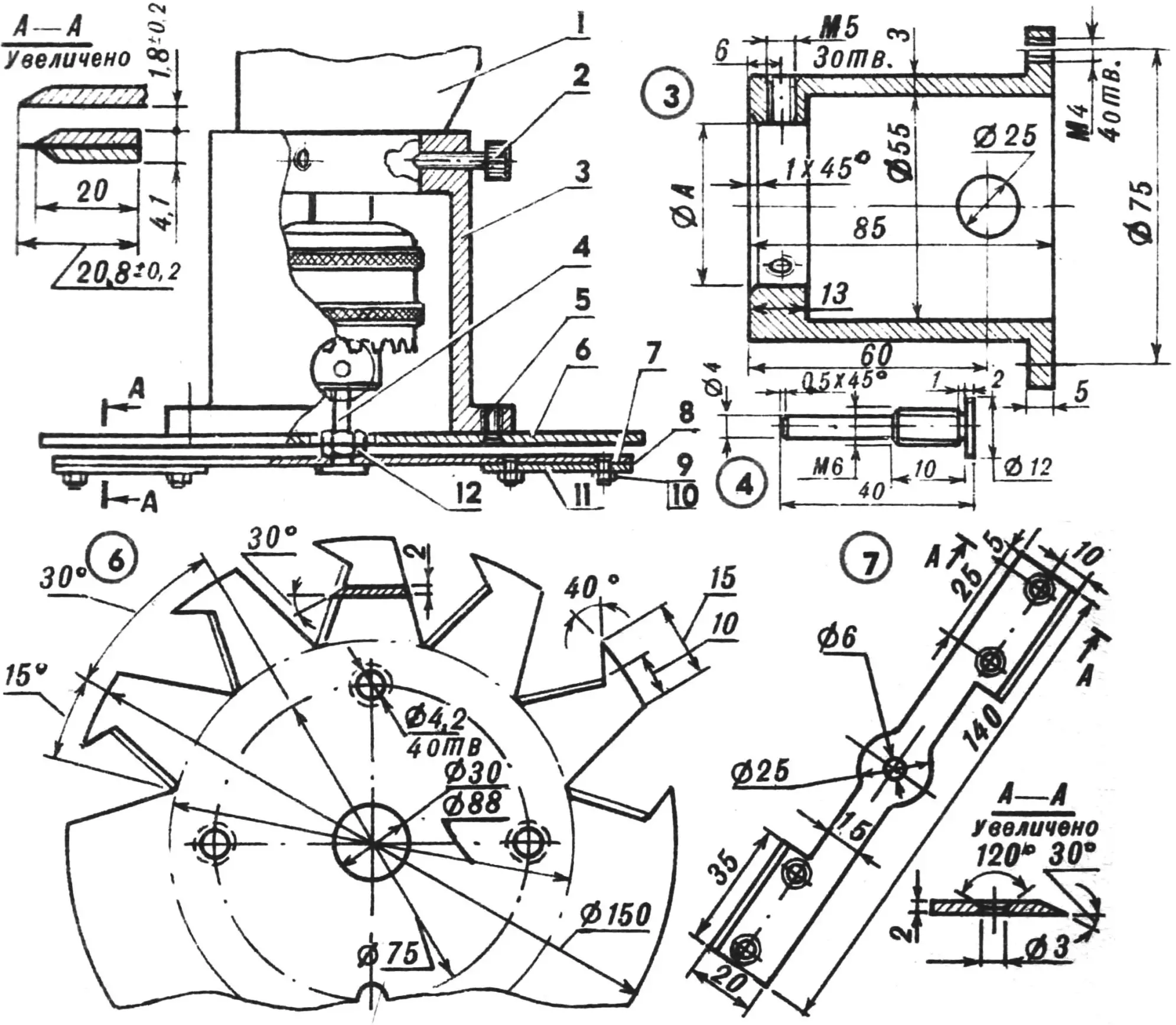

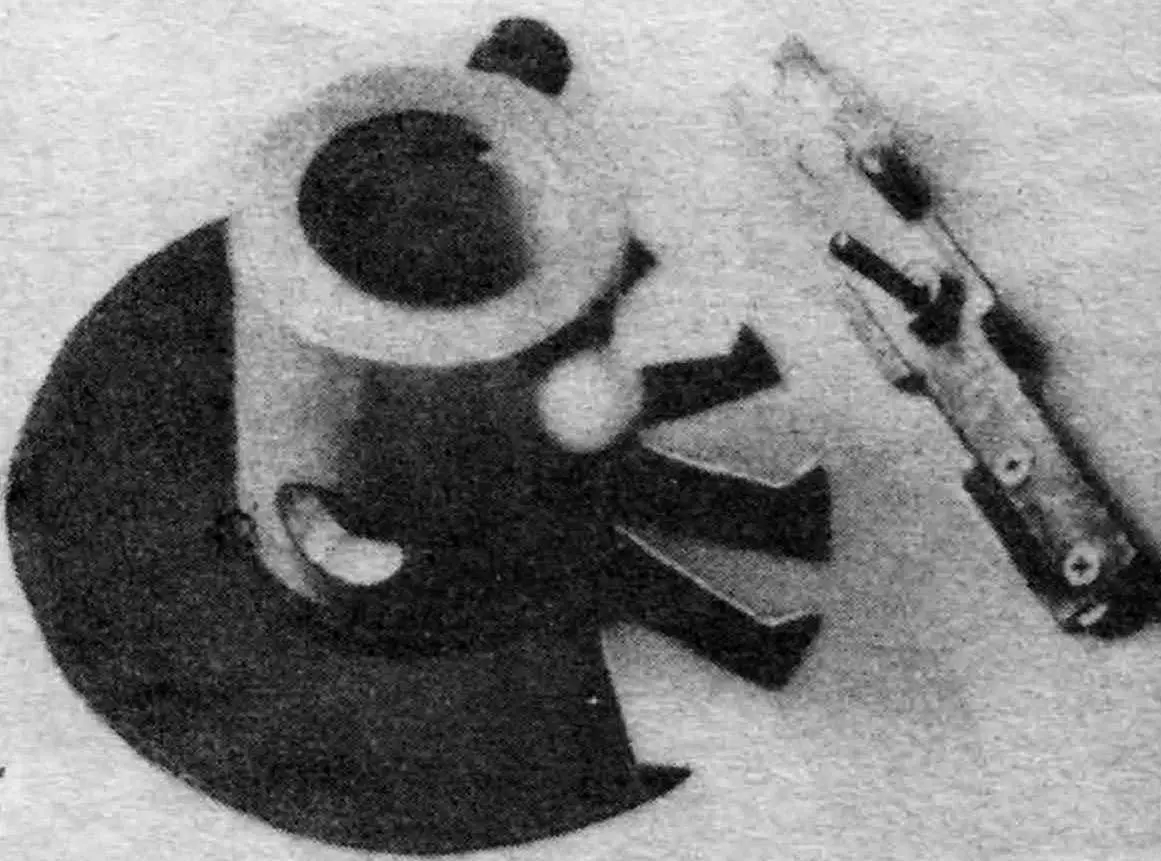

1 — drill body, 2 — M5 screw with knurled head, mounting (3 pcs.), 3 — cup (St3), 4 — axle-shank (St5), 5 — M4 countersunk screw with conical head (4 pcs.), 6 — housing (St3), 7 — blade (St5), 8 — “Neva” razor blade (2 pcs.), 9 — M3 countersunk bolt with conical head (4 pcs.), 10 — M3 nut (4 pcs.), 11 — clamping bar (St3, 2 pcs.), 12 — M6 nut (2 pcs.).

There are no hard-to-find seals, “floating” knives, or self-aligning bearings in my hedge trimmer design. The materials are the most common, the kinematics are the simplest (see illustrations). And the weight is minimal. And for a hand tool — this is far from an unimportant factor. The design of my hedge trimmer can even be lightened a bit more (there’s a reserve of strength and reliability!), by replacing the steel cup, body, blade, and clamping bars with duralumin ones.

The cutting elements are the ends of the blade, on which razor blades clamped by clamping bars are mounted. Moreover, the latter are inserted so that they protrude 0.6—1 mm (in the direction of drill chuck rotation). This prevents breakage of the cutting edge. In addition, using razor blades frees you from the constant need to worry about the sharpness of the cutting element.

During operation, centrifugal force stabilizes the blade with “knives” secured in the drill chuck in the radial direction. The razor blades clamped in the sockets easily cut bushes, trim green plantings, turning the previously monotonous and tiring work into creativity, and the “garden hairdresser” himself into a sculptor, a landscape artist.

The blade with “knives” is covered from above by a protective housing. It has two halves that differ sharply in shape. The solid one performs purely protective functions. The ray-shaped one, while preventing blade breakage, simultaneously serves to capture the branches being cut and direct them right under the “knives.”

The protective body is attached to the cup, which connects to the drill body, with four M4 screws (countersunk, with conical head). The design and mounting of the other parts are clear from the illustrations. The manufacture of my developed hedge trimmer attachment will cause no particular difficulties for anyone (I’m sure!). Nor will there be any during operation: the tool is convenient, simple to use, reliable in operation. Make yourself one — you won’t regret it!

“Modelist-Konstruktor” No. 5’93, A. KHIKMATOV, Tashkent