To fix the sail on the mast provided the so-called mast pocket doubled folded strip of fabric, tutu is to the luff of the sail.

Note that many of the seams on the sail is best done on a machine of type “zigzag” sutures of this type are elastic and do not pull the fabric. However, the seams that connect the individual panels together, sewn with a straight stitch — these stitches the sail to stretch out to anything.

And three absolutely necessary parts of a sail — reinforcing scarves in falavam (top), galava [bottom! and Shkotovo (rear) corners of the sail. They are cut from thicker fabric (thick canvas or tarpaulin) and fixed to the sail with seam “zigzag”. In Shkotovo and gipsowa corners is secured powers brass bushing intended for kertikov — braces of the sail. Instead of powers it is possible to fix some plastic (polyethylene) washers or rings, tightly almetov their thread and then cut the sail and gusset holes.

Mast windroller is a duralumin pipe with a diameter of about 40 mm and a wall thickness of 2 mm. However, it is possible to whittle the mast from quality pine bar out of the package or flat grained boards with a thickness of about 10 millimeters. Wooden mast should be tapered in the upper part of the diameter should be about 30 millimeters, at the bottom — 55 mm.

And the last piece of the mast — hicok-wishbone, resembling two bows put together. Make it the easiest way of duralumin tubes with a diameter of 22 millimetres at the front fixed poluchaut of wood or PCB, which wishbon fit in with the mast and a rear — bolt with washer and wing nut.

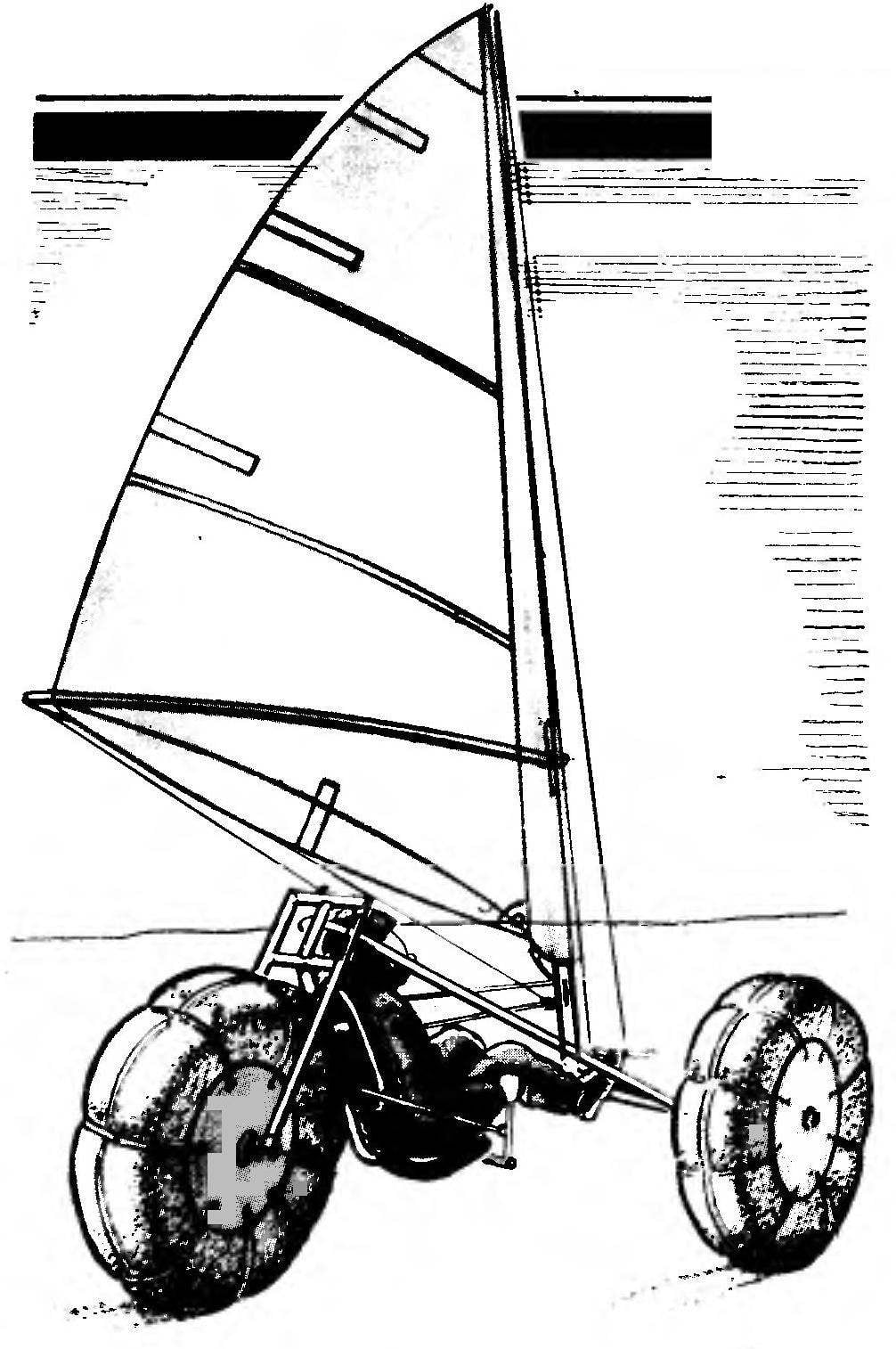

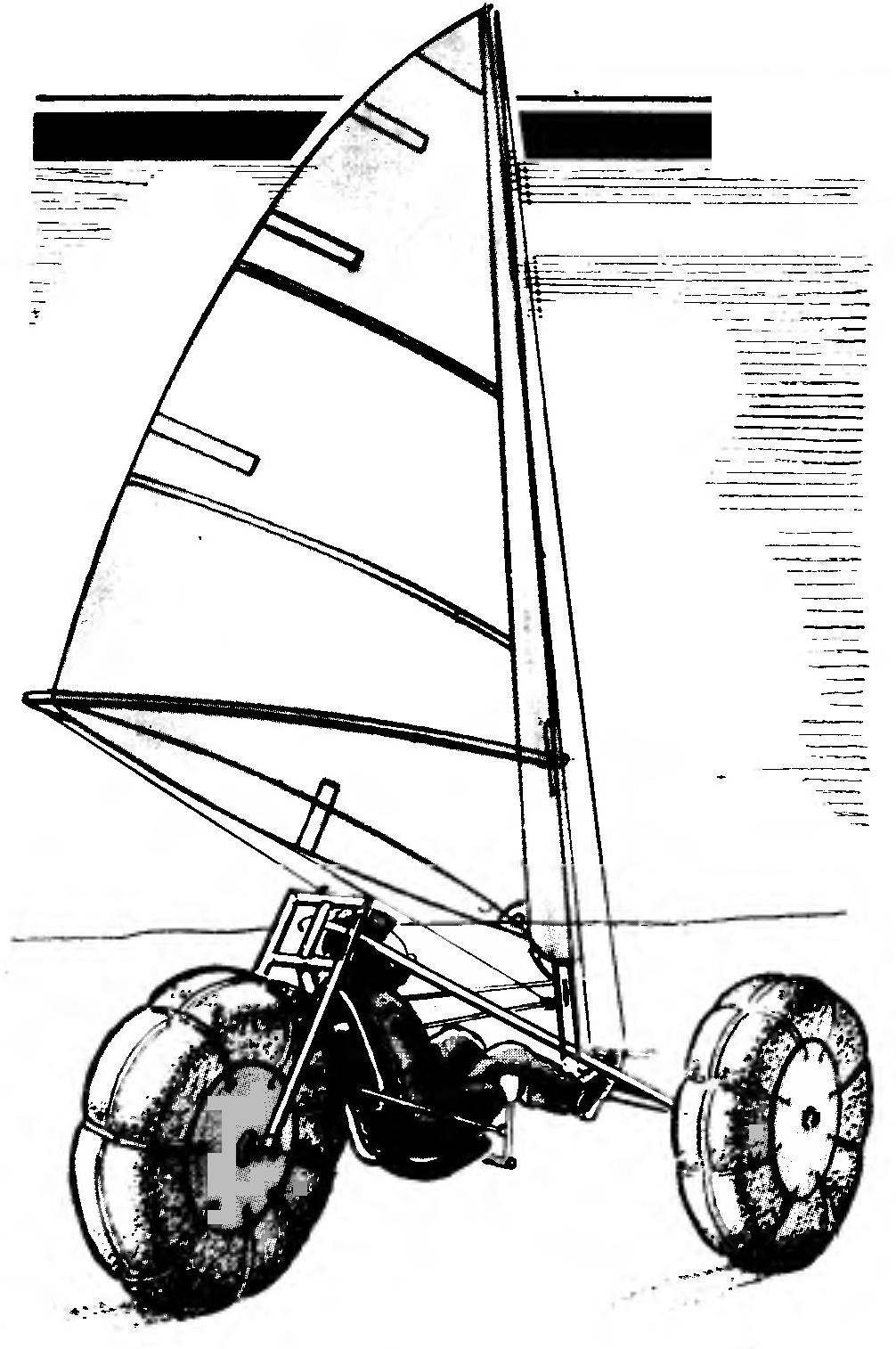

Pneumatic wheels windroller — camera truck. Depending on their geometrical parameters are selected and the sizes of wheel hubs. The basis of each amount of the sleeve — cuts steel pipes with welded thereto flanges and pressed into them with bushings made of bronze or PTFE.

Wheels are cut from plywood with a thickness of about 12 millimeters on the sleeve, they fixed the MB bolts and nuts, and with each other are connected through a long steel threaded rods, nuts and washers. Assembled thus the wheel has an acceptable rigidity and strength. If the size of the hub is chosen correctly, the camera does not mount. However, smooth Pneumatics can not only roll, but also to “drift” — to slide sideways. That is why the tires needed some type of protectors. For this circuit is quite suitable nylon rope, passed through located on the rims hooks or staples covering the camera.

The front wheels rotate on the axle shafts — steel threaded studs mounted on the front beam of the frame using rubber bushings. This bushing is located between the two nuts and washers on the axle shaft, and then is embedded in the pipe, then the remainder of the outside nut is tightened; the rubber sleeve when it “swells” and firmly secures the axle shaft into the beam.

Rear wheel installed in the fork with a long threaded rods, two washers and a couple nuts with lock nuts. Turns windroller carried out using two levers, connected steering rods with controlled fork.

To equip, or, as sailors say, to arm windroller pocket of the sail is stretched on a mast, and then her nylon certicom fixed hicok-wishbone; the same certicom, passed through the eyelet sheet angle the sail is pulled to the rear wishbone.

Thus prepared, the sail (with mast and wishbone) is inserted into the designated glass trolley and nylon certicom, passed through powers the tack angle and the struts, natugo stretched on the mast. The same skertic simultaneously captures the mast in a glass carriage.

Control the sail with nylon rope — the sheet. One end is fixed to the rear of wishbone, and the other sequentially passed through a block mounted on a shoulder strap (bracket) of the steering fork, through the block on the mast Cup, and finally falls into the hands of the steering (the driver).

A little about the technology driving windroller. Start moving it is best when quite fresh wind, whose direction — side or side-rear (sailors call these the direction of the wind relative to the course of the sailing ship “galfvind”). The first phase (acceleration) is performed on flat ground. Sailboat to start is oriented relative to the wind (sheet in this case must be fully restrain). The helmsman sits in the driver’s seat, and selects the sheet until, until zapalskiene sails. At the same time, the assistant starts to disperse windroller; if the sail starts to zaprashivat, the driver picks up the sheet a little. Reaching a certain speed, the sailing ship continues to move by themselves, and the pull of the sail will allow you to move and not too flat terrain and not too deep snow.

Be especially careful when cornering. As is well known to yachtsmen, they are of two types — tacking when sailing in the process of turning the bow crosses the wind and achieve, and turn before the wind, wherein the wind line crosses the feed of a sailing vessel. I must say that the first is significantly safer, although sometimes causes some hitch in the movement. More rapid rotation of the wind, although fraught with the overturning of a sailboat through the nasal part with a sharp transfer of the sails from one side to the other.

Note, windroller brake has not. Finishing the movement, we should dramatically expand it against the wind and completely upset the sheet — it causes almost instantaneous stopping of the sailing ship.

We wish you success in the manufacture and development of windroller; hope that this land sailboat will help you in the shortest time to acquire the quality mentioned in the beginning.

Sailing has always been considered a true male. And not by accident: this sailor has the necessary power and speed of reaction, physical endurance, ability to keep calm in even the most difficult circumstances. However, sailing there are two significant negative First — seasonality in our mid-latitudes means to do it can be no more than five months in a year. And second, the need fairly large areas.

Sailing has always been considered a true male. And not by accident: this sailor has the necessary power and speed of reaction, physical endurance, ability to keep calm in even the most difficult circumstances. However, sailing there are two significant negative First — seasonality in our mid-latitudes means to do it can be no more than five months in a year. And second, the need fairly large areas.