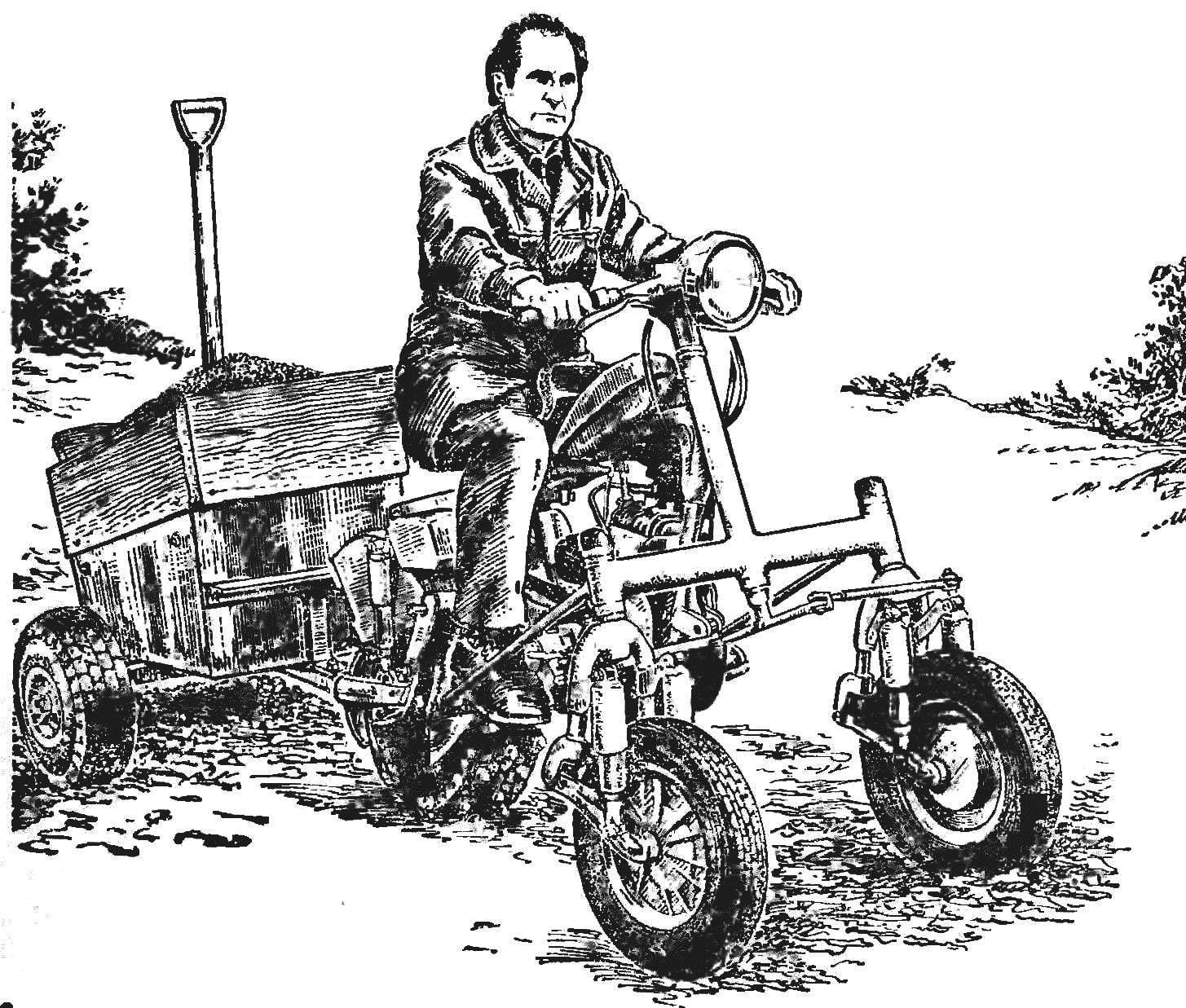

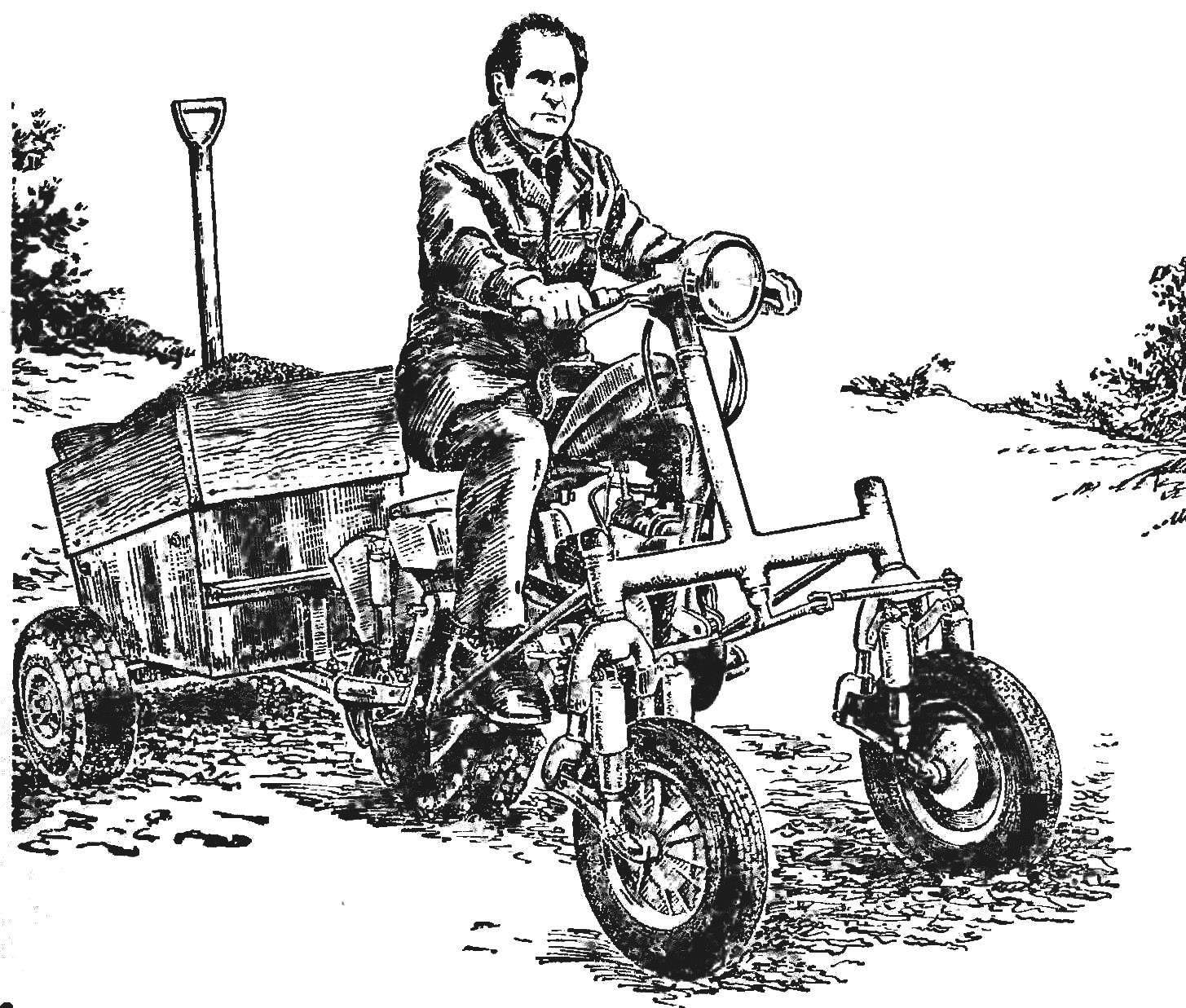

In addition to towing at speeds up to 30 km/h truck with a load of 600 kg, the tractor performs a number of other tasks. For example, working with a forward bulldozer type knife, oblique snehapanam, mechanical forks for wings and moving stacks of hay, a mower with the seizure of 1,200 mm, three-row Hiller-cultivator, plow.

Pulling power of the machine ensures the engine T-200 with forced air cooling. Torque from the output sprocket of the engine (12 teeth) chain is transmitted to the intermediate shaft (30 & 13 teeth) away from the sprocket of a back sprocket (46 teeth), planted on the brake drum scooter.

Fig. 4. The scheme of installation of the seat :

1 — seat 2 — upper beam of the frame, 3— tube-bracket, 4 — absorber, 5 — a bracket of fastening of the shock absorber and the engine.

The frame of the tractor is made of tubes of rectangular cross section and of metal strips, are widely used in ready-made components and parts. Its design at first glance seems complicated. But it is not. The front suspension of the scooter taken from “Electron”. The only addition to it welded to the steering blocks with a length of 140 mm suspension fork to right — back in the course of the trailer, to the left — forward. The levers are connected by rods with a rocking chair attached to the steering shaft. The latter rotates in the column on thrust bearings. Steering wheel with controls, lighting and monitoring devices is taken entirely from the scooter.

The engine is located on the lower beam of the frame on three brackets with slotted holes that allow you to slightly move it and thereby to change the tension of the drive chain. Power is supplied from moped fuel tank, hosted a “motorcycle” on the upper beam of the frame.

Fig. 5. Conical spike :

1 — stud,2 — screw M10, 3 — lid,4 — washers.

Stanan intermediate shaft will prepareda bearing No. 206; he is wearing a block sprocket (keyed) and eyes (bronze bushings) pendulum fork. Pulled the last pin M12. The second pin M12 going the rest of the pendulous fork, make the welding of bushings-spacers and two pieces of a steel strip 50X15 mm, to which the bolts of the towing bracket. The weld needs to be very reliable, as they have large loads.

The axis of the rear wheel is fixed in the eyes of the pendulous fork, allowing you to adjust the tension of the driven chain. It remains unchanged when vertical vibrations of the wheel because the axis of swing of the fork and the rotation of the intermediate shaft are the same.

The towing bracket is an arc of steel band reinforced at the sides with two fatty pads. Back in its thickened part, pressed on steel pin 14 mm. d him hooked drove a replaceable working bodies, including bogies.

R and S. 6. Ball spike ;

1 — ball d 20 mm, 2 — bolt M8, 3 — ring ball bearing,4 — tire .

The Dolly consists of a T-shaped frame, welded from a steel profile 50X50 mm, the ends of which is provided with a bracket carrier and axles; two of the tires (they can be replaced by dual motorcycle wheels) and bodywork from sheet metal. The latter is installed on the frame so that the center of gravity located ahead of the wheels. Thus several loads in addition the rear wheel of the tractor, which improves its adhesion to the soil.

It remains to add that the conical spines, which are provided to the rear wheel of the tractor, good especially for soft soil. When driving on rocky surfaces it is better to use the spikes made of branovan ball bearings: they have a good hardened steel, and the spikes will serve reliably for a long time.

0. OSTAPENKO, Vinnitsa

Recommend to read TIMER MODEL HELICOPTER In aeromodelling clubs of the pioneer of the Kominternovsky area, obsut and Kharkiv high school № 112 in a few years, work is underway on the co-axial model helicopters. Their designs... SHOWER FOR CAM Engine classic Vase (2101 -2107) is very reliable and durable unit, easy to operate and easy to maintain. However, he has his own "Achilles heel" — the camshaft, it is highly...  Original and practical design vinnichina Oleg Ostapenko A. obviously liking the readers of our magazine. After the transfer of the Central television “you can” in which the editorial Board takes an active part, and the publication of “Panorama” some of the technologies that Amateur constructor in our mailroom received many queries about the features of these machines. That is why in number 4 of the journal for this year, we have placed the description and drawings of two-wheel tractor-tug, and now provide page numbers for story of a three-wheeled tractor-wagon, adapted for operation in complex terrain.

Original and practical design vinnichina Oleg Ostapenko A. obviously liking the readers of our magazine. After the transfer of the Central television “you can” in which the editorial Board takes an active part, and the publication of “Panorama” some of the technologies that Amateur constructor in our mailroom received many queries about the features of these machines. That is why in number 4 of the journal for this year, we have placed the description and drawings of two-wheel tractor-tug, and now provide page numbers for story of a three-wheeled tractor-wagon, adapted for operation in complex terrain.