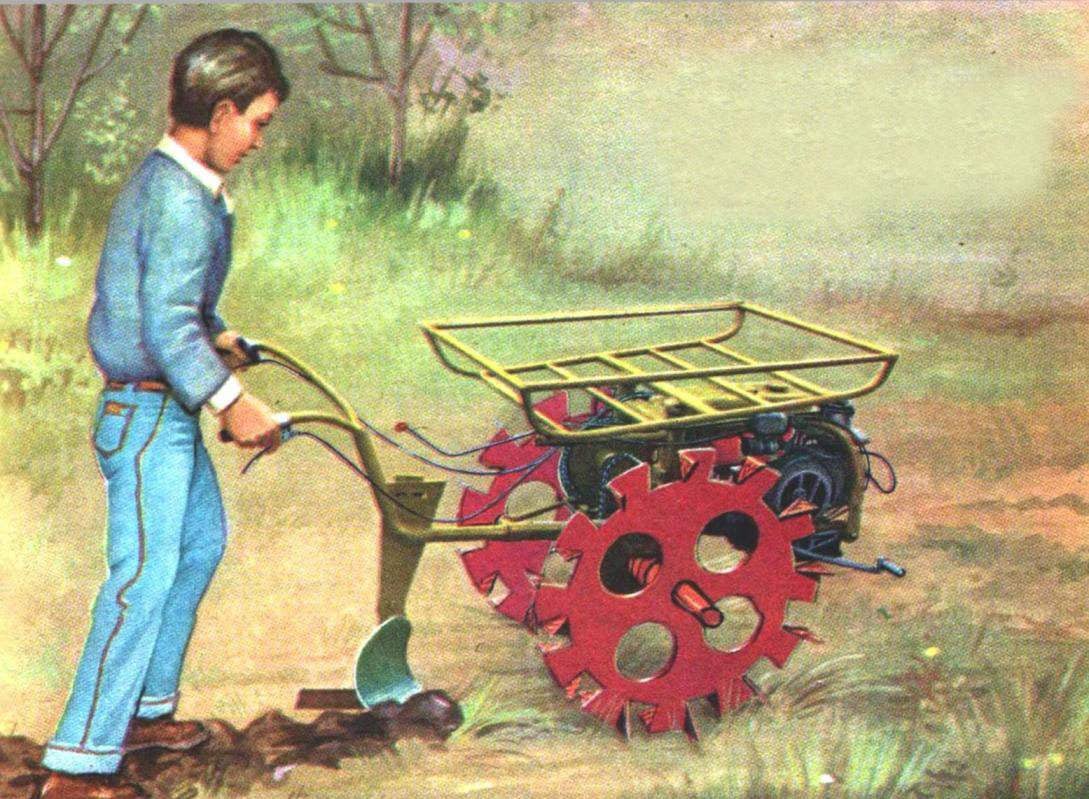

During operation, the plow overcomes the resistance of the soil, often puts also in the side, and the farmer, working with motor-plow rigid structure, have to make considerable efforts to align furrows. Arkhipov such an inconvenience eliminated: the vehicle of the plow located under some angle to the direction of movement. This position is governed by three hinges thrust. Walk-behind tractor during plowing slightly rotated to the left, compensating for the drift.

When carrying out the first furrow (most important moment) to hold a direct direction by the plow because the tiller arm is rigidly connected with him, not with the tillers. When they turn with little effort all the device changes the direction of motion. For example, it is necessary to turn to the right. Plowman rejects… arm in the opposite direction. And as the plow cannot move there — he seems to be pinned to the ground, then thrust, going behind the arms, turns the tillers to the right.

The second and subsequent grooves control is simplified because the right wheel is in a furrow as the copier.

Cultivator, harrow and rake set by the regulatory thrust exactly in the middle of the track. Attach those two bolts, and plow. The brackets of these guns slightly expanded in the vertical plane to compensate for the angle at which was installed the plow. To the harrow bracket welded in the middle vertically. Such a harrow when driving a farmer can manage, omitting, if necessary, one or the other side and smashing large clods.

Fig. 5. Wheel.

Fig. 6. The management node:

1 — connecting axle, 2 — strip, 3 — tube, 4 — arm.

Fig. 7. Connecting elements:

1, the main rod 2 and control rod.

On uneven ground, the harrow does not respond to various inclinations of the tillers. (And in rigid connection with them, it copies them, leaving the blemishes.)

For planting potatoes Arkhipov uses the cultivator is removed from the dumps. Installing it in place of a plow, he spends a furrow in the ground and puts them in the tubers. Then puts in place the blade and plowed the tubers, allowing the cultivator between the furrows. Similarly asociada and germinated planting.

Cultivator Arkhipov and digs — vpahivat — harvest. Grip width changes the dumps.

Tops remaining after harvesting, and missed the potatoes is removed by the harrow or rake. The latter, incidentally, conveniently raking in heaps of mowed grass.

In addition to agricultural work, tillers Arkhipova applies, in particular, for snow removal. In addition, it sets only a small dozer blade. Can and sidewalk sweeping, putting additional sprocket and a roller with a round brush.

Those interested can consult V. N. Arkhipova, by writing to the address: 248025, Kaluga, Tarutinskaya str., 2A, office 1.

As evidenced by the mail, under the heading “Small mechanization” is very popular among people whose work directly or indirectly related to agricultural production. Of particular interest to readers are self-propelled mini-tractors — tillers. After “M-K” has published a description and drawings of “Vyatich” (see No. 7, 1981), built by engineer S. A. Ilyicheva, Amateurs agricultural design write and call the editor with a request to continue the conversation on this topic.

As evidenced by the mail, under the heading “Small mechanization” is very popular among people whose work directly or indirectly related to agricultural production. Of particular interest to readers are self-propelled mini-tractors — tillers. After “M-K” has published a description and drawings of “Vyatich” (see No. 7, 1981), built by engineer S. A. Ilyicheva, Amateurs agricultural design write and call the editor with a request to continue the conversation on this topic.