Water motorcycles, or scooters, are very popular among water motor sports enthusiasts and athletes. This type of transport has expanded the range of watercraft, contributes to the development of tourism and promotes active recreation, allows you to better explore your region on weekend trips…

But what if there is only a small pond or stream in the garden plot or village? An interesting version of a water scooter with a flipper propulsion system was proposed by the guys from the Young Technicians Club of Kolomna.

The flipper oscillations are carried out using a bicycle handlebar. At the same time, the micro-scooter can move in any direction, demonstrating unique maneuverability. Such capabilities can be fully applied on a small body of water when playing “tag”. Riding a scooter allows you to quickly “pump up” the muscles of the arms, legs and abdominal muscles in a playful way. The micro-scooter has a small weight (18 kg) and is easily carried by the handles fixed on the deck, and its small dimensions allow it to be transported on a car roof rack. The absence of a noisy gasoline engine allows the micro-scooter to be used, practically, on any available body of water.

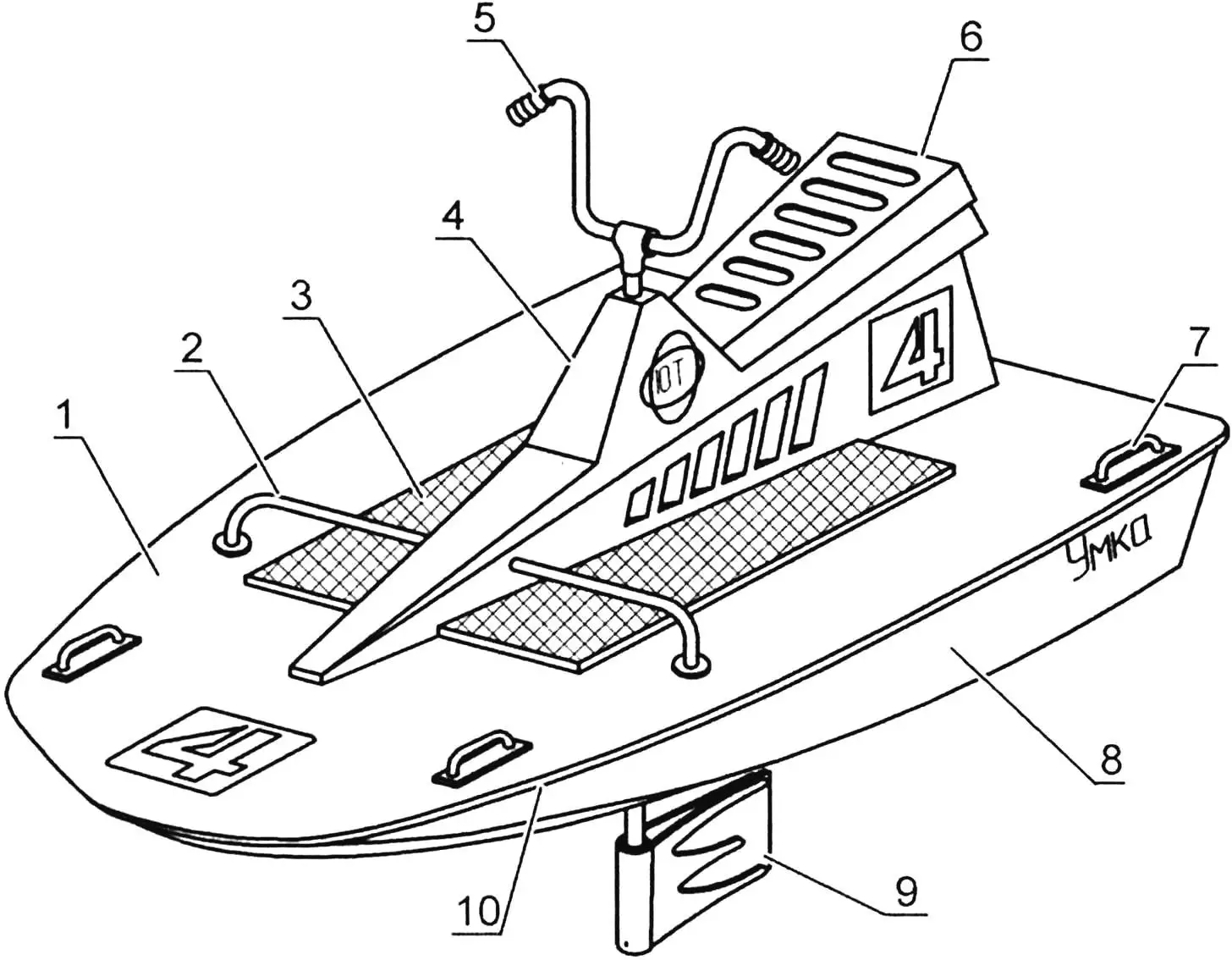

1 – deck; 2 – footrest; 3 – mat; 4 – seat support; 5 – handlebar; 6 – seat platform; 7 – handle; 8 – micro-scooter bottom; 9 – wave propulsion – flipper

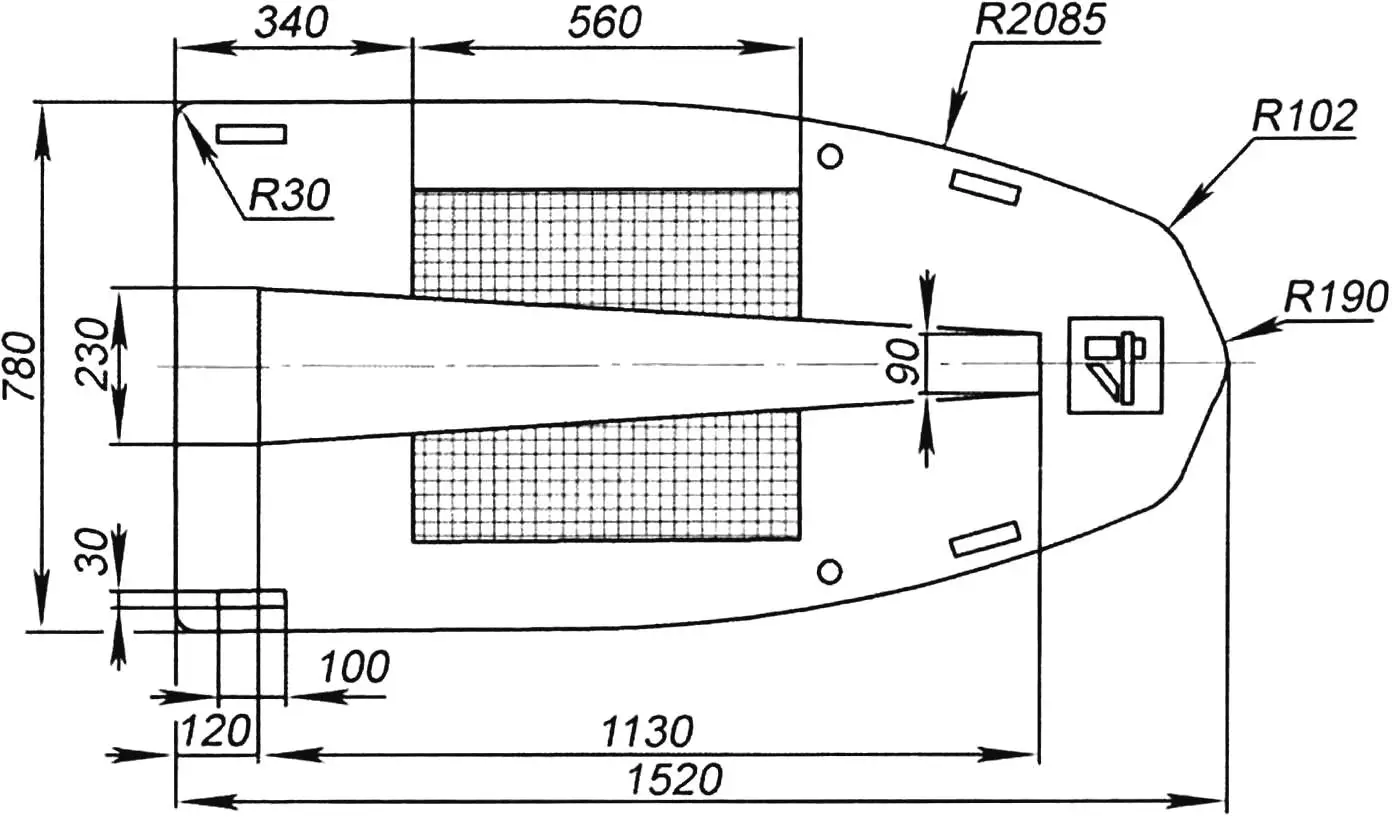

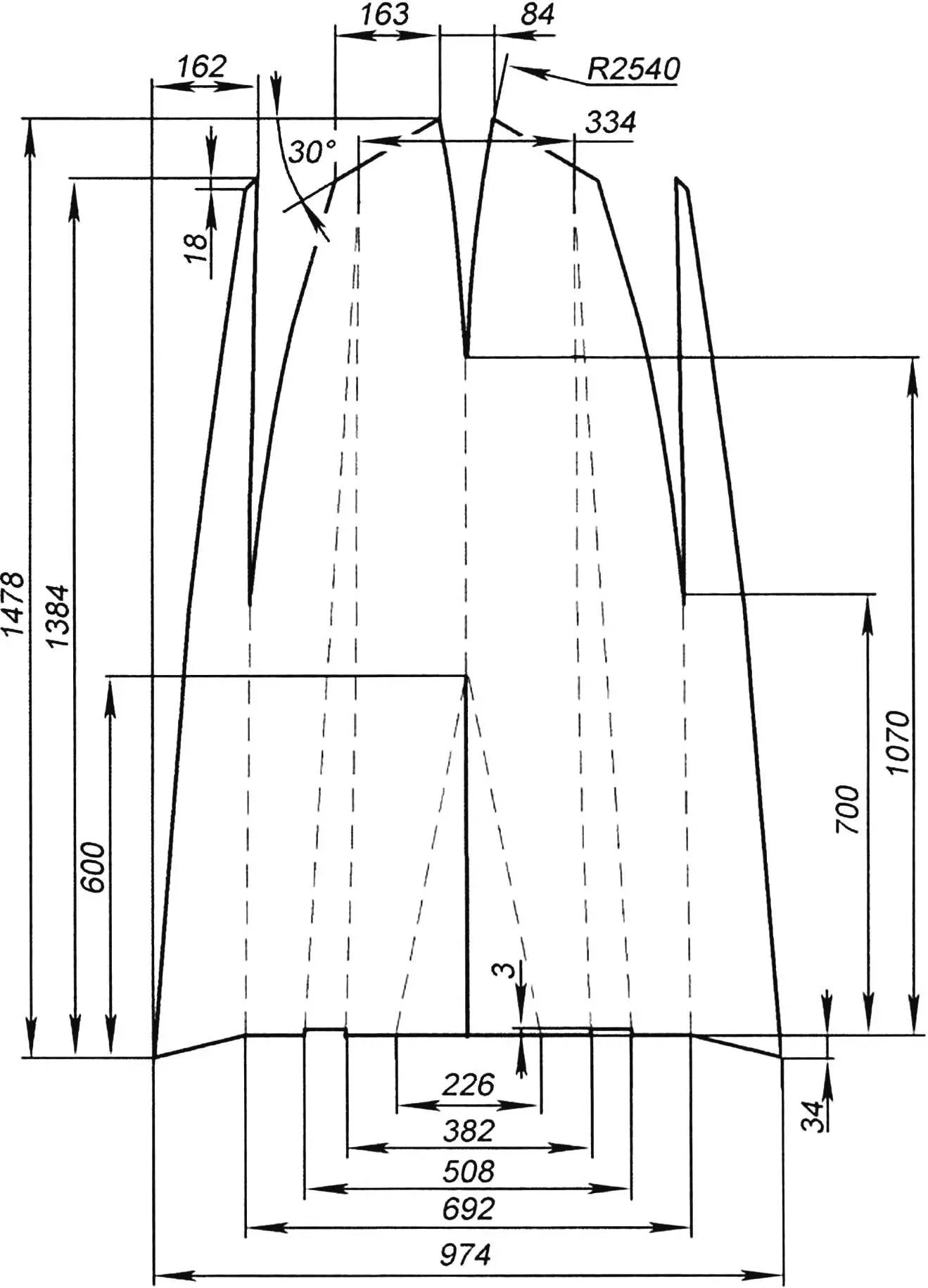

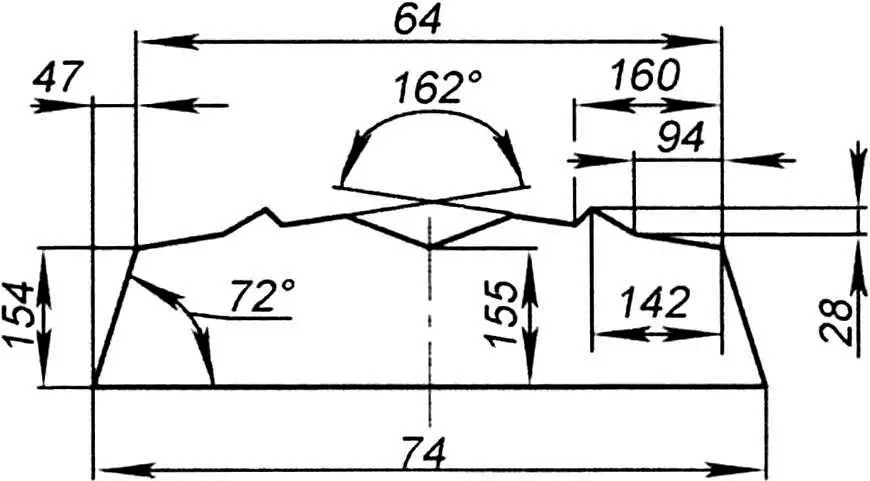

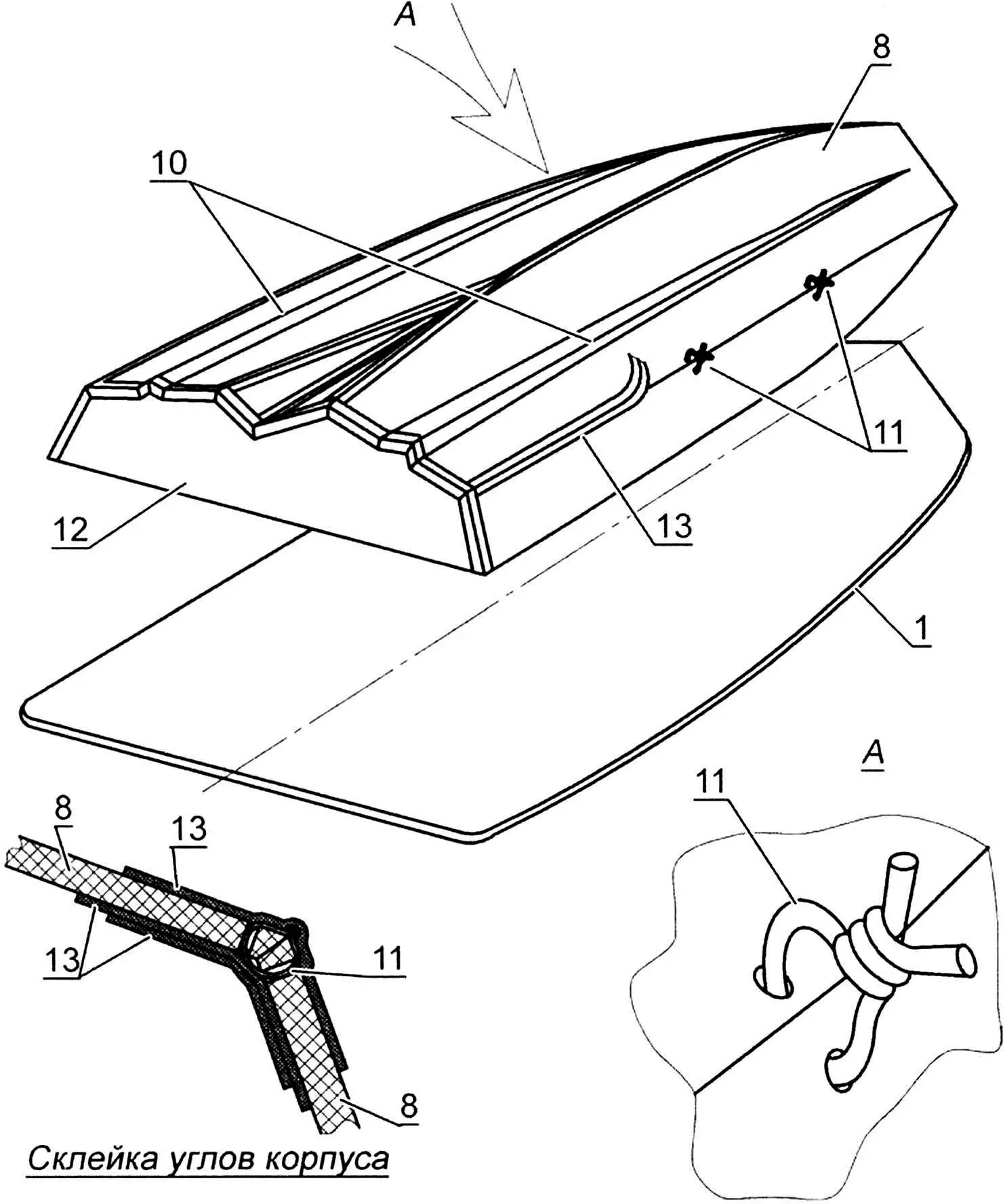

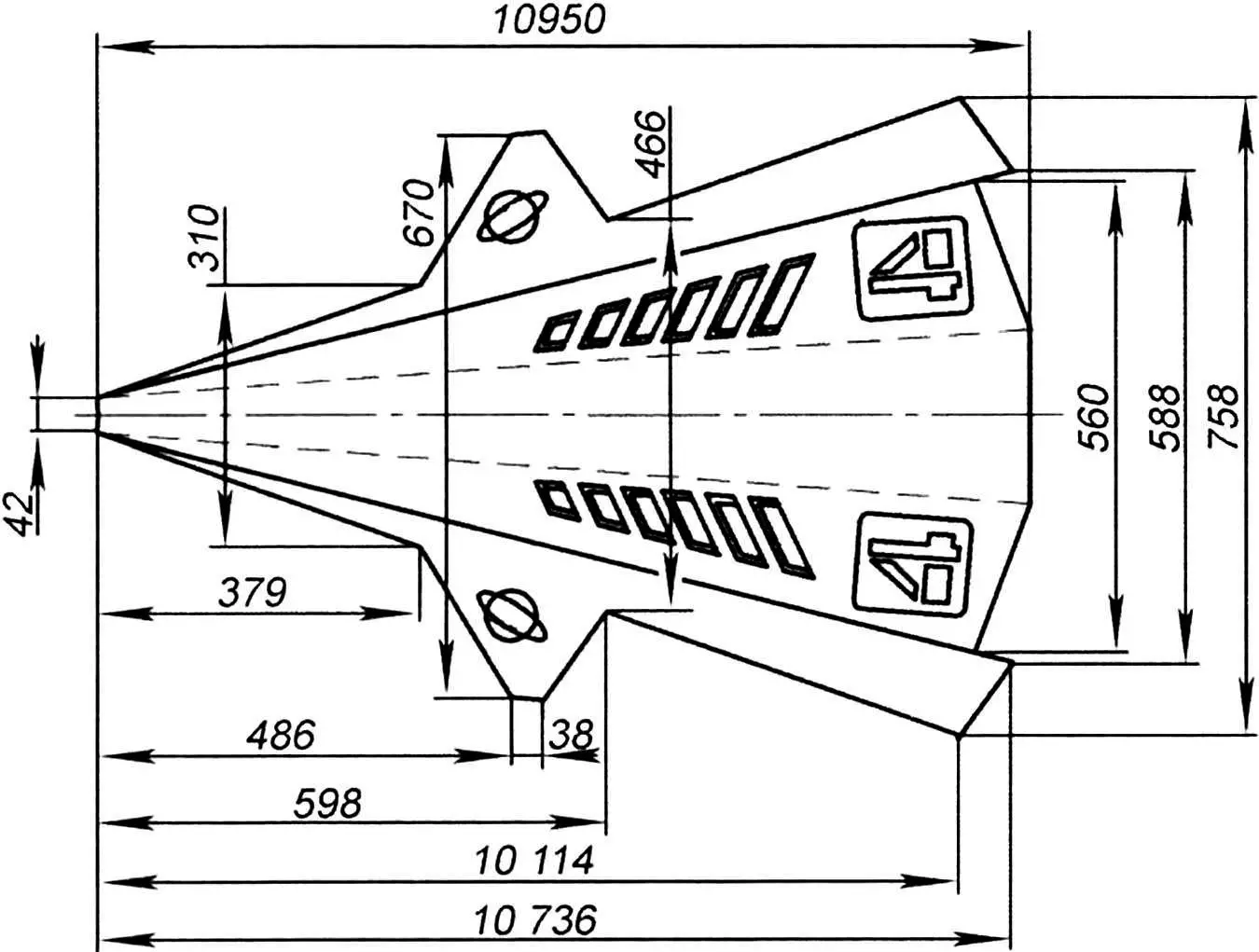

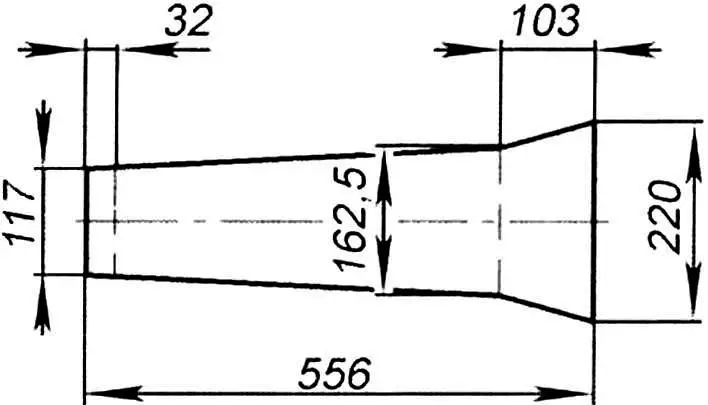

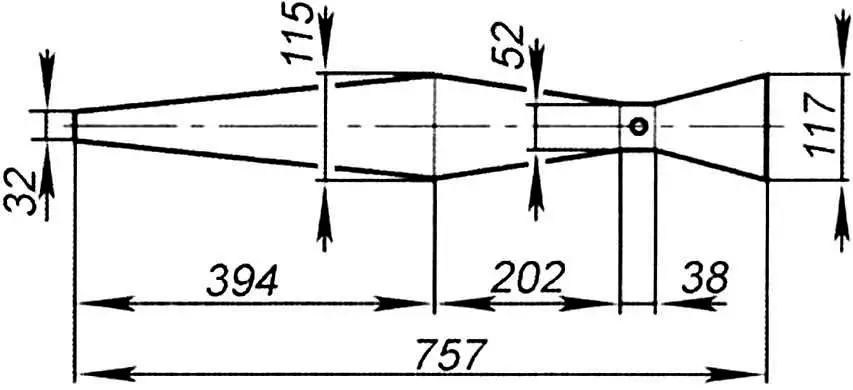

If someone wants to make a similar scooter (fig. 1), start its manufacture with the deck (1), the dimensions of which are given in figure 2. We recommend cutting the deck from 3-mm plywood according to the drawing we propose. The bottom (8) can also be made from thin plywood. Do this: transfer the development outline (fig. 3) to thin plywood or hardboard and cut it out. Along the dotted lines, cut the blank to half the thickness of the plywood. Bend the sides along the transom contour (fig. 4). Only note that the dotted lines (fig. 3) on the bottom planes (in the form of triangles) serve as a guide for gluing triangular strips (10) – stiffening ribs (fig. 5). Along the edge of the connecting planes at a distance from the edge, drill pairs of holes with a diameter of 1 mm for wire twists (11), as shown in figure 5 (view A) with a pitch of 150 – 200 mm. After twisting the hull sheet blanks with wire, carefully glue the corners from the inside and outside with strips of fabric on waterproof glue. The triangular groove in the center of the stern part of the hull serves to increase the stability of the small vessel – the stern of the hull splits and acquires catamaran qualities.

Then secure the transom (12) with glue.

A lighter hull can be made from thin sheets of construction foam, glued with overlap. Process the foam with an ordinary grater. In any case, the corners of the hull should be covered with thin fabric (13), as shown in figure 5. Glue any version of the hull to the deck.

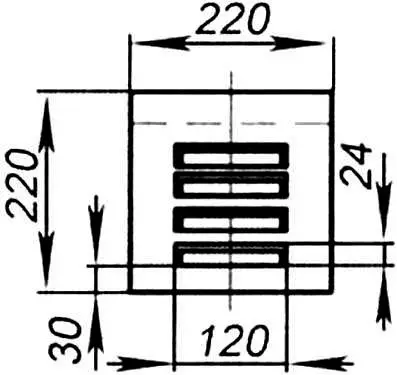

Next, make the seat support in the form of a box or crate. To do this, cut out the side panels of the seat support from thin hardboard or plywood and glue wooden strips with a cross-section of 20×20 mm along the profile contour. To facilitate installation, we recommend using small nails.

Now you can cut out and glue the front (fig. 9) and rear (fig. 10) overlays onto the seat sides. After the glue has completely dried, impregnate all internal and external surfaces once or twice with synthetic drying oil. Paint the external surface to your taste with bright PF series enamels. Using furniture corners located on the outside, attach the seat support to the micro-scooter hull. Use screws as fasteners.

Using a feather drill (“perka”) for wood, drill a vertical through hole with a diameter of 30 mm in the seat support and according to the marking in the hull – for the handlebar stock.

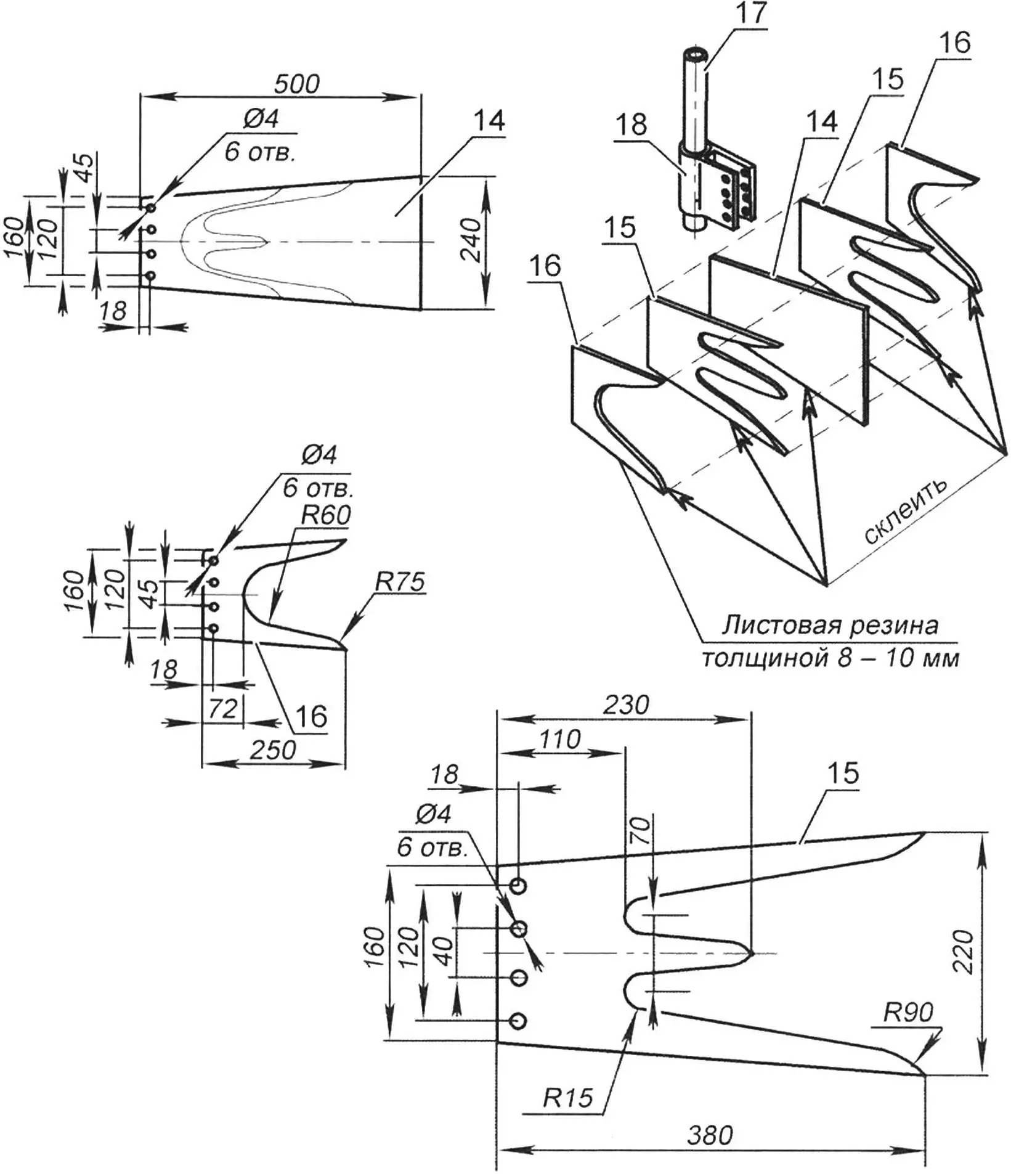

To prevent water from entering the hull, you need to glue in a vertical plastic tube that serves as a stern tube device (fig. 10), which also ensures easy oscillatory rotation of the propulsion system. Make the stern tube device as follows: take a bicycle handlebar (5) and extend its vertical tube – the stock (17) to 800 mm. Lubricate the stock with grease and wrap five to six layers of fiberglass on epoxy resin around it. You can use regular fabric. It is desirable to obtain an outer diameter of the plastic tube (20) of about 30 mm – according to the size of the holes in the hull and seat support. Glue the resulting blank into the hull. Thoroughly coat all seams with a “mash” of epoxy resin and wood sawdust. After gluing, cut off the excess material of the vertical tube so that the upper part protrudes by 150 mm, and the lower part – by almost 60 mm. The size is determined by the available flipper in order to ensure its circular rotation.

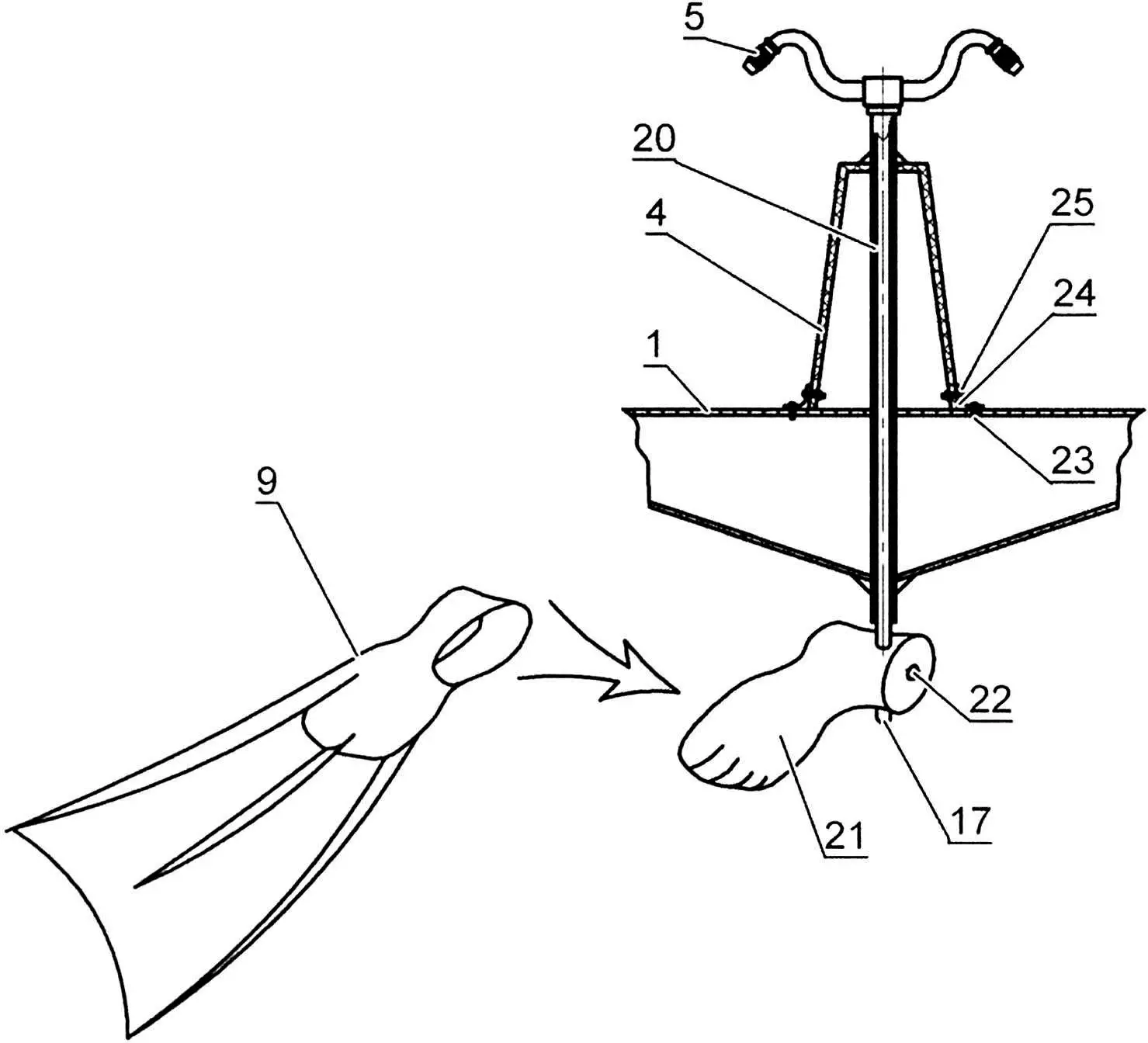

Insert the handlebar stock into the stern tube device and secure a wooden blank (21) from below with a screw (22), imitating a swimmer’s foot. The blank serves for quick putting on of a rubber flipper (9), purchased in a store, as shown in figure 11, and a homemade one (fig. 7).

The flipper can be made from thick rubber by gluing it as shown in figure 7. Cut out the central part of the flipper (14) and glue two side overlays (15 and 16) on both sides with rubber glue. Secure the resulting rubber flipper (9), as shown in figures 1 and 7, on the handlebar stock (17) using an overlay (18).

For carrying the micro-scooter, secure four door handles (7) on the deck using screws.

To prevent feet from slipping on the deck, install, as shown in figure 1, a footrest (2) and mesh overlays – mats (3). Make the footrest from a tube from an old folding bed. From foam rubber 50 mm thick, make a soft seat (6) and cover it with leatherette. Attach the cushion to the seat support using small screws.

Now you can test the scooter on the water and once again be convinced of its unique maneuverability. Try moving forward and backward, as well as mooring while moving sideways, sharply changing the direction of movement. If you and your friends make several such machines, you can play the popular game “Tag”, as well as arrange a short trip along the river.

In conclusion, we recommend wearing a life jacket before each game. If your scooter accidentally capsizes, don’t panic – with a sealed seat support and the same hull, it returns to normal position on its own. It is best to get on the scooter from the water from the stern, resting your feet on a rope tied to the rear door handles. We wish you happy sailing!

“Modelist-Konstruktor” No. 10’2016, V. GORIN, A. EGOROV