the Designers often have to choose the right transmission ratio, and in this regard to look for suitable veins. The case is ungrateful, requiring large expenditures of time. It is much easier to do the right sprocket myself. Especially because making them at home is not so difficult.

the Designers often have to choose the right transmission ratio, and in this regard to look for suitable veins. The case is ungrateful, requiring large expenditures of time. It is much easier to do the right sprocket myself. Especially because making them at home is not so difficult.

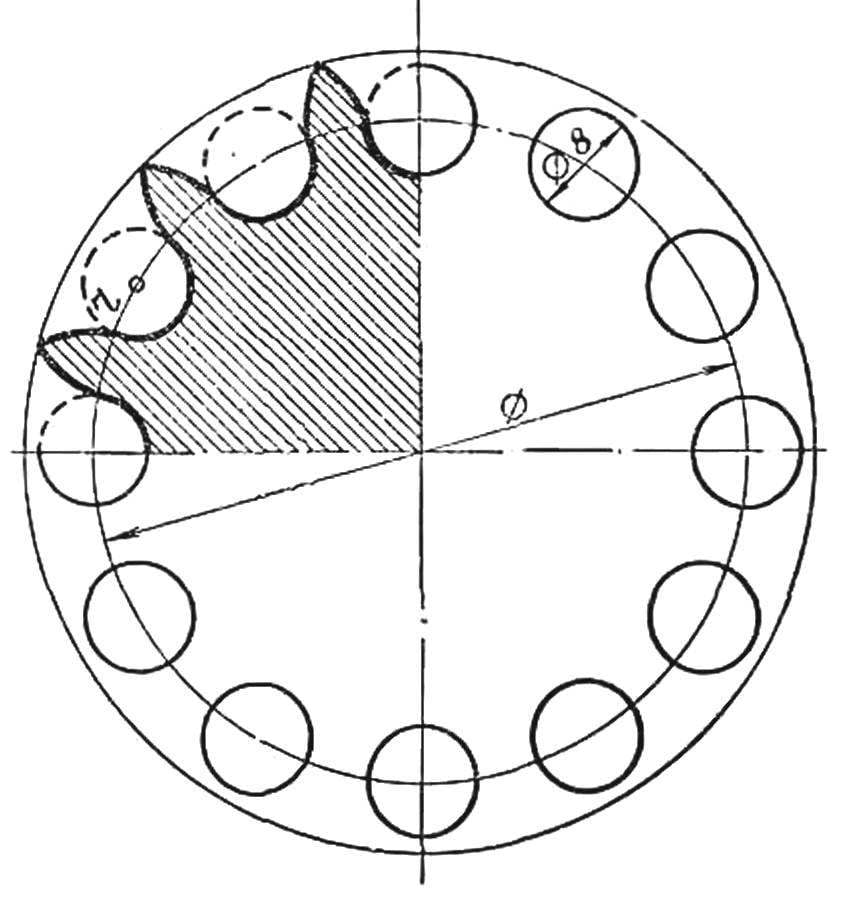

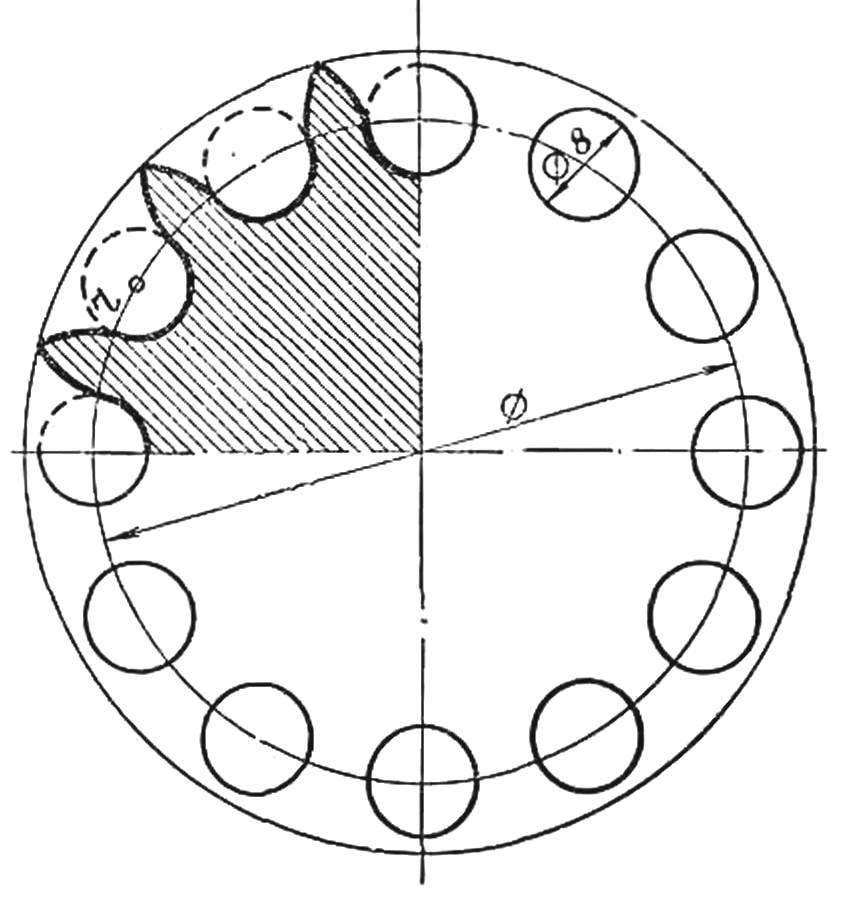

For example, you need to make a sprocket for a Bicycle with 12 teeth. On a steel plate with a thickness of 2.3 — 2.6 mm is plotted as a circle, the diameter of which is calculated according to the formula: (12.7 X n)/3,14 + 0.5 mm, where 12.7 mm — step Bicycle chain, n — number of teeth (n=12 the diameter is 6.0 cm).

At the intersections of the radii and the inner circle, which is taken by 16 mm smaller than the outside, drill a hole ø 8 mm. the Excess metal is removed with a hacksaw, the ends of the teeth are made in a vise with a file.

In the manufacture of sprockets for motorcycle chains need to take the steel with thickness of 5.5 — 6 mm. in the calculation in the formula we need to substitute the value of the step varying the chain.

I. LAGUSA