To perform work on the cylinder liner is made mandrel. Its structure is clear from the figure, we focus only on certain details.

The anode — steel stud; one end over a length of 50-60 mm welded lead-antimony (7-8%). Lead eat through the outside diameter of 6 mm (for working sleeves Ø 15 mm). On the other hand threaded studs to secure the wire.

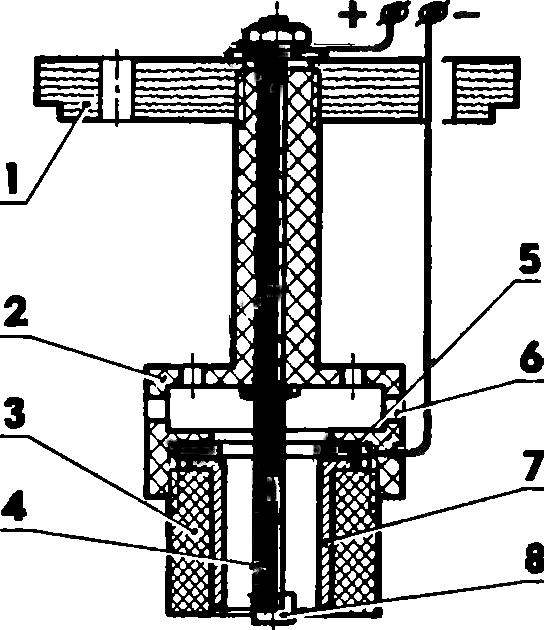

Mandrel for chrome plating of cylinder liner:

1 — cover (vinyl), 2 — top Dolly (fluoropolymer), 3 — the lower part of the mandrel (PTFE), 4 — anode (steel), 5 — cathode, 6 — through window for the passage of the electrolyte, 7 — covered casing, 8 — nozzle insulator.

The cathode is a ring with an inner diameter of 0.5 mm greater than the internal dimension of the sleeve. It chekanitsa cut insulated wire. Copper and brass conductors, it is better not to use — the electrolyte dissolves them, and the contact may be broken. Before installing the plug in the bath is useful to check the reliability of the contact tester.

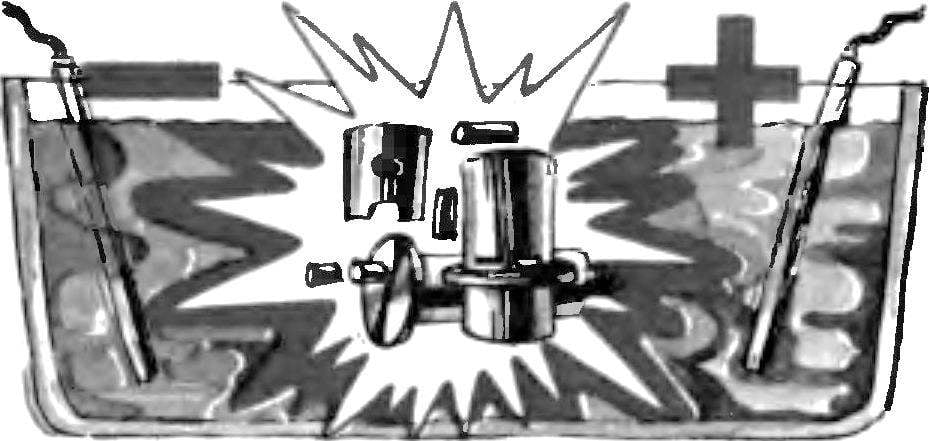

Mandrel for chrome plating of shaft and piston pin:

1 — anode, 2 — cathode, 3 — crankshaft 4 — cone-mandrel, 5 — piston pin.

Chrome plating of steel parts (crankshaft, crank pin, piston pin, bearing races)

Chrome plating of steel parts is conducted according to the following technology:

— remove grease with gasoline,

— rinsing in hot soapy water,

— handling the details of the reverse current within 2-3 min,

— switch to chrome plating with a current 2-2. 5 times as large as estimated, and the gradual reduction of current for 10-15 min.

Rated current is determined by multiplying the square of the chromium coated surface on the current process. To become the latter — 50 A/DM2 . In chrome plating, for example, seats in the main bearing on the crankshaft of the engine KMD-2,5 rated current is equal to 0.03 DM2 X 50 A/DM2 =1.5 A.

The chrome crank pin will need a new mandrel. As in the processing of the crankshaft, all exposed areas of the surface of the closed glue “AGO”. The anode is machined from steel, followed by casting of the lead and bore holes finger. The use of steel parts due to the need to provide reliable contact to the lead screw connections are unreliable. The calculations of currents of the same. Work is carried out in the mandrel shaft via a special nozzle.

Virtually no different chrome bearings. The only — to protect the internal part it is filled with grease or other grease which, after the coating is washed with gasoline.

Bar the chrome outer cage of the bearing:

1 — housing mandrel bearing, 2 — bearing, 3 — decorative nut, 4 — anode (lead), 5 — Central part of the mandrel for chrome, 6 — cathode (steel), 7 — cover, 8 — through window for the passage of electrolyte.

A mandrel for chroming of crank pin:

1 — crankshaft (cathode), 2 — through window for the passage of electrolyte, 3 — anode, 4 — the screw of fastening of a cover, 5 — the details of the mandrel (PTFE).

The concentration of chromic anhydride in the electrolyte is controlled by a hydrometer. The concentration of sulfuric acid is only possible to determine, unfortunately, indirectly, the quality of the coating.

In the chromium plating process is evaporation of the electrolyte. In these cases, water is added to the desired level. This is done without setting the details — you can change the temperature of the electrolyte.

After chrome plating, all products subjected to heat treatment for 2-3 hours to remove the hydrogen at a temperature of 150-170°. All work is carried out under an extractor device, rubber gloves and glasses.

Yu MASSALITIN, master of sports of the USSR

Recommend to read HOUSING BLOCKS OF Sectional block method of construction of the larger vessels have proven their effectiveness. It will be useful to modelers. Normally, the body size wikiepedia on the disc, is assembled... CHEVROLET TAHOE The sale of this American car-SUV began in our country in 2008, and the first presentation of the car took place in the United States two years earlier under the motto All-new for 2007...  To perform work on the cylinder liner is made mandrel. Its structure is clear from the figure, we focus only on certain details.

To perform work on the cylinder liner is made mandrel. Its structure is clear from the figure, we focus only on certain details.