10 years have passed since the moment when on the ice kartodromo countries started regularly played the championship of the Union and the RSFSR. In the winter competition includes two classes of racing and two classes of models-copies of planes with compression engines of 1.5 and 2.5 cm3. Today’s theme is the racing model of the sleigh, their schemes, design features, propellers, etc.

10 years have passed since the moment when on the ice kartodromo countries started regularly played the championship of the Union and the RSFSR. In the winter competition includes two classes of racing and two classes of models-copies of planes with compression engines of 1.5 and 2.5 cm3. Today’s theme is the racing model of the sleigh, their schemes, design features, propellers, etc.

So, kordovye racing model of the sleigh classes 1.5 and 2.5 cm3. They are simple, not costly and complicated equipment and can be made in school workshops in the classroom, in self-similar circles syt and clubs independently.

At the present time, there have been stabilized in two directions — more precisely, the two schemes most progressive layouts racing. After all, the very concept of “race” suggests that from the model it is necessary to obtain speedy result, and if so, the main requirements — reliability, simplicity of design and of course good speed.

Typically materials for these models are plywood thickness 6-8 mm, sheet aluminum with a thickness of 1-2 mm, pine and fir boards, tin plate, lime bars for fairings, hornbeam, beech, birch or deletedrevision for propellers. The choice of materials depends on the design of the model and local features.

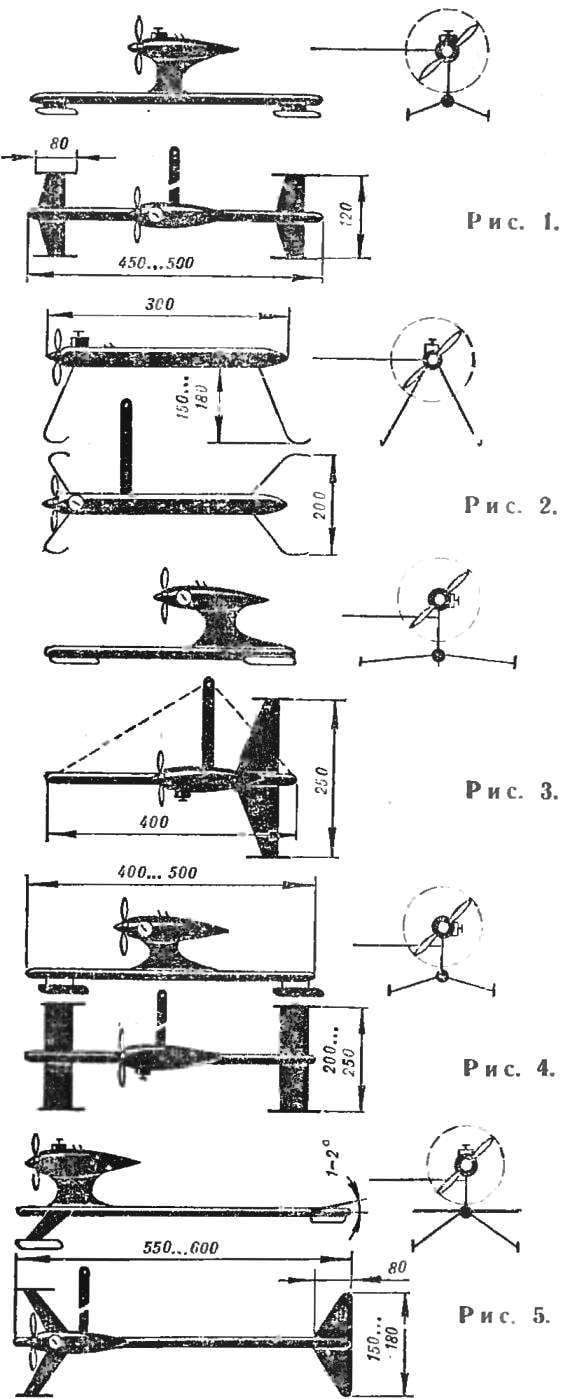

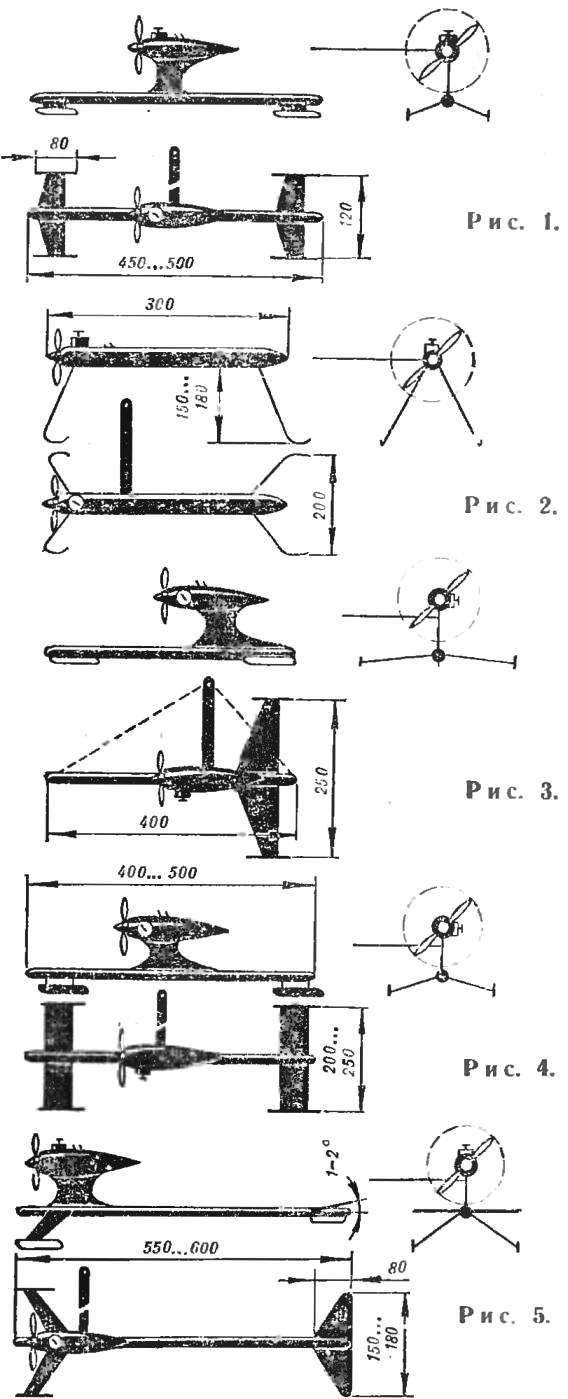

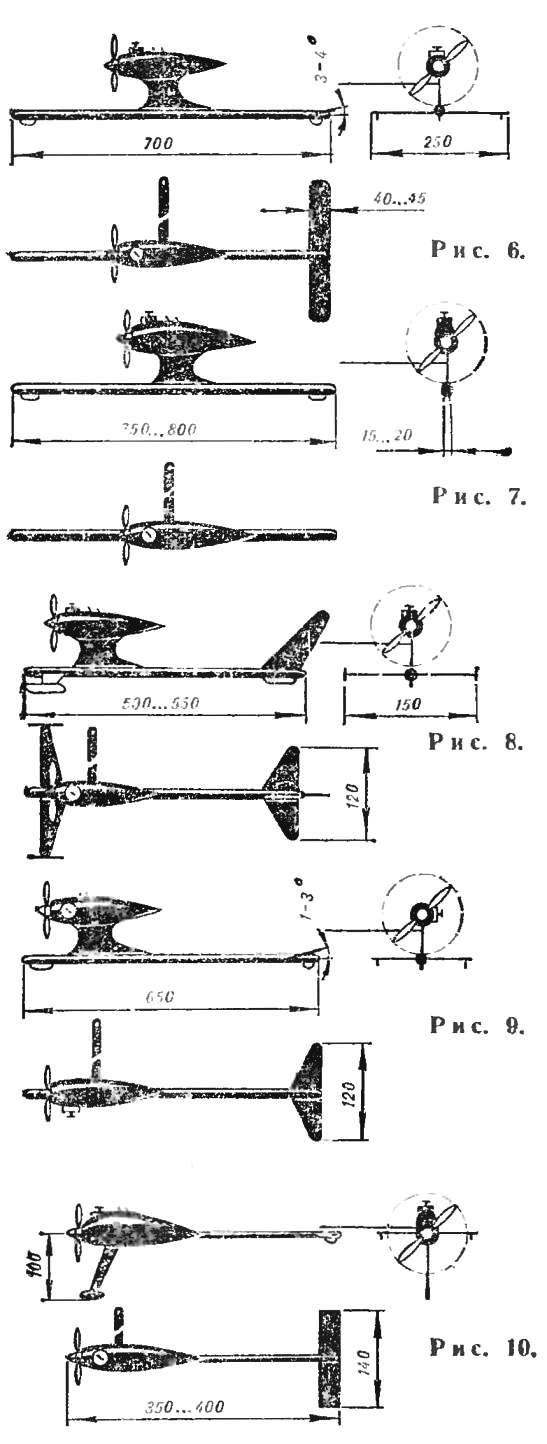

Consider the most common scheme.

Figure 1 shows a diagram of the model with a vertical engine. Its under engine frame is made of plywood, the engine is closed by a fairing (the engine head is open), and the case of pine slats, suspension and skates — sheet duralumin, instead of cord strap previously mounted bridle made of steel wire. Speed engine MK-12B and “Rhythm” — 100-115 km/h. the Model is very unstable on the ice, tends to rise above the track due to suspension.

The model layout is shown in figure 2, was applied by many athletes. Engines “Rhythm” or KMD-2,5 it travels at a speed of 120-130 km/h. Volatile only at the time of launch. The suspension system (wire-skates-spring) does not meet the current rules of the competition.

Figure 3 shows a model, design which on the second all-Union competitions suggested Tyumen athletes, but it is not justified because of low performance: awkward crank and unstable movement (inside the circle) to the start. Speed with the engine “Rhythm” reached 120 km/h.

Many have applied it in the circuit shown in figure 4. Suspension models are made of steel wire, Ø 2-2. 5 mm, skates — from sheet aluminum or steel. The engine is located horizontally with the head on the outside in the course model; it keeps track, with the engine developing “Rhythm” speed of 130-135 km/h. Disadvantage — does not run.

Models in figures 5 and 8 are about the same in its driving qualities. They have three or four points of support, but when entering a restricted speed due to wing off the track in between rear skates that reduces friction on the track. Speed with the engine “Rhythm” up to 145 km/h.

On the second all-Union competitions in Perm for the first time demonstrated the model presented in figure 6. It was built by the guys from the city of Tchaikovsky, Perm region. She showed the perfect of that time the result: more than 160 km/h. However, the model was equipped with the engine with glow ignition. But at the time, this scheme, despite its apparent progressiveness, they are not widespread. And only after switching to the compression engines, when the search began for options to improve speed of results, again referred to the offer of the Perm modelers. At the fifth all-Union competitions the athlete from Tyumen A. Anicii to model this layout with the “Rhythm” reached a speed of 150 km/h.

Good result showed a model of a compression engine “Super tiger” 2,5 cm3 (Fig. 7). It is built in Penza modeller mi. The length is about 700 mm, engine is located in the middle of the body rail under engine frame is cast, the engine is fully zakoptelova, skates located directly on the body and suspension, the distance between the skates in pairs standing 10-15 mm. Screw pitch 200-220 mm Ø 160 mm, the speed of 170 km/h. a Model of sustainable on-the-go, keeps track if any quality of ice.

Figure 9 shows the schema model of self-similar laboratory of the Tyumen regional syut. Its length is 650 mm, weight 370-400 g front sub-frame of 7-8 mm plywood, the engine KMD-2,5 positioned horizontally (head lap in the course of the model) and fully zakoptelova. The propeller at step 220 km is Ø 160 mm. model Speed of 165 km/h For the engine RITM use screws of the same diameter, but with a pitch of 230 mm, the velocity reaches 150— 155 km/h. the Model runs in the direction of clockwise, stable when running, keeps track even on very bad ice. The movement is only on the front suspension the ridge, which is achieved by a positive setting angle of the stabilizer.

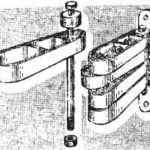

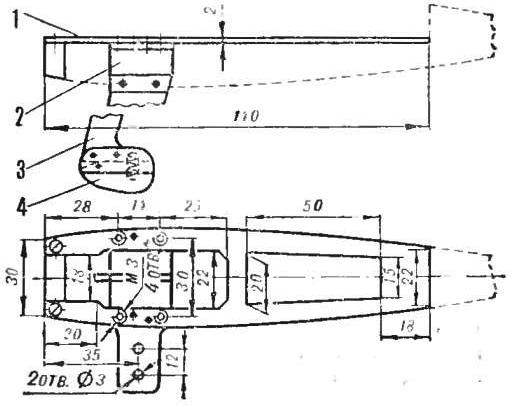

Fig. 11. Chassis racing model sleigh with engine MK-17:

1 — motor, 2 — bracket, 3 — strut, 4 — skate.

Excellent speed quality show models made according to the scheme shown in figure 10. For the first time this arrangement was chosen Omsk modelers. At the all-Union competition, held in 1977 in Zelenograd, an athlete from the town of Zavodoukovsk, Tyumen region, Yuri and Kosintsev on the model of such scheme, equipped with compression engine “meteor”, the result showed 183 km/h. Sub frame, make a cast or sheet aluminum with a thickness of 2-2,5 mm, length about 400 mm, weight 370 g.

The engine is usually placed vertically, but it can be put horizontally (head lap in the course of the model). The movement is only in a counterclockwise direction, as when running the model lies on his left side due to the reaction of the screw, and in this case, cord strap plays a role of additional support. A compression engine MK-17 the speed of such models is 135 km/h.

It should be noted that on bad ice, they do not keep track, often looking up from the surface. This can be avoided by applying a simple system podruzamevaet front of the skate, the construction of which will be described below.

THE MODEL OF A SLEIGH SMK-17: MOTOR MOUNT AND SUSPENSION

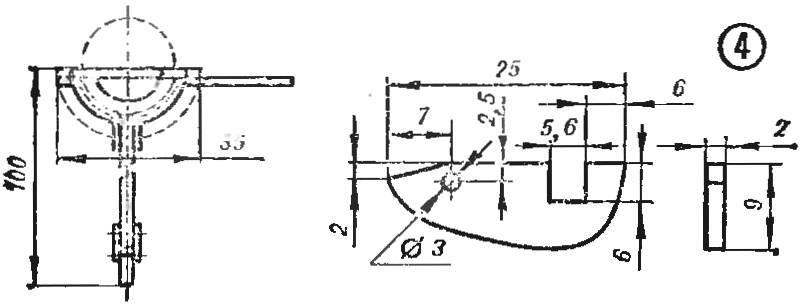

Rational design of sub-frame and suspension proposed by the modelers of the Tyumen regional station of young technicians.

The frame is made of sheet duralumin with a thickness of 1,5—2 mm with riveted it with aluminum rivets, two steel bracket, bent in accordance with figure 11. They also have three roles are the basis of the sub-frame, are the elements of the mounting upright and a cord strap.

Marked out and drilled holes in motorhome, cut them in threads M3 for fixing the legs of the engine. Made of aluminum with a thickness of 3 mm manufactured rack support front of the skate and attach it to the bent parts of the brackets of the frame. On the bottom, pre-processed part of the support riveted the two pads. In the groove to the ridge insert the dural plate-mandrel with the thickness of 3 mm and through her nasverliv holes, Ø 5.5 mm for the coil spring suspension. After that plate is removed. Of steel sheet of thickness 1,5—2 mm produced the skate and insert it into the groove of the support. Then drill a hole Ø 3 mm under the axle of the skate. The front part cut down so that moving contact point was in the range of 3-4 mm.

Spring front suspension compression, its outer diameter is 5 mm. Length and spring stiffness are chosen so that under the weight of the model is almost fully compressed. In the spring, lay a piece of rubber from the vacuum hose that serves as a damper. Under engine frame-side projecting mount is closed fixed fairing, fixed with epoxy glue. To increase the strength of the connection under engine frame savelives over the entire area of the drill bit, Ø 2-3 mm, followed by razzenkovkoj from the engine mounts.

Review of designs of sleigh racing has produced a V. Ogibenin