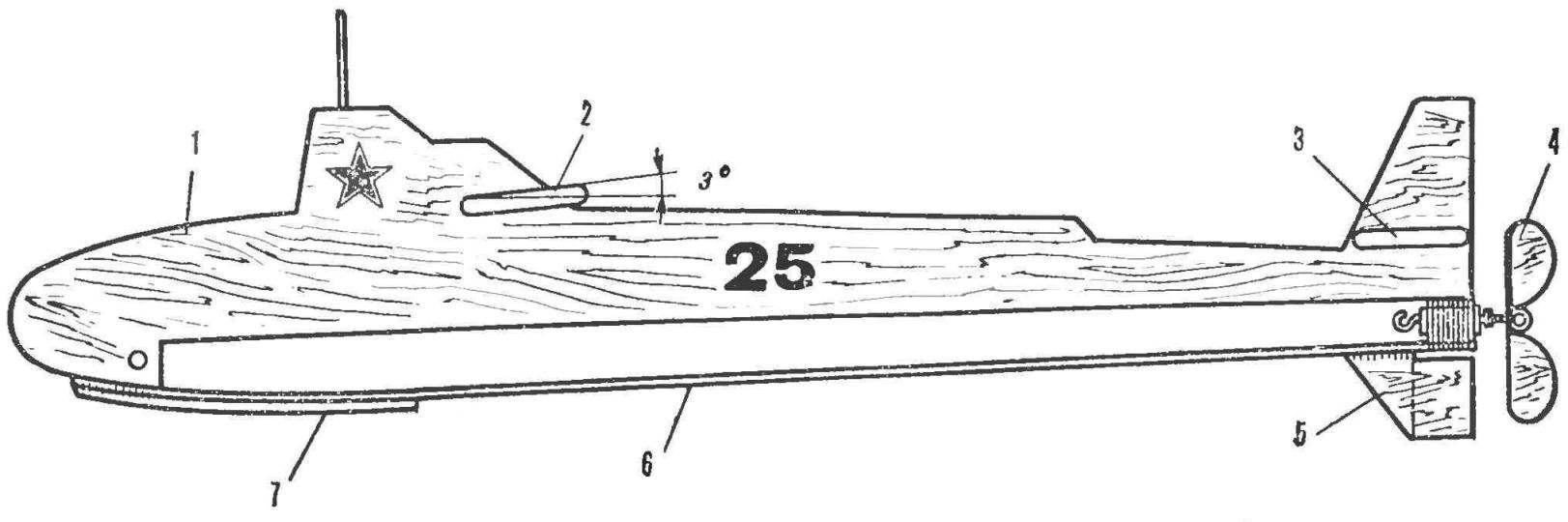

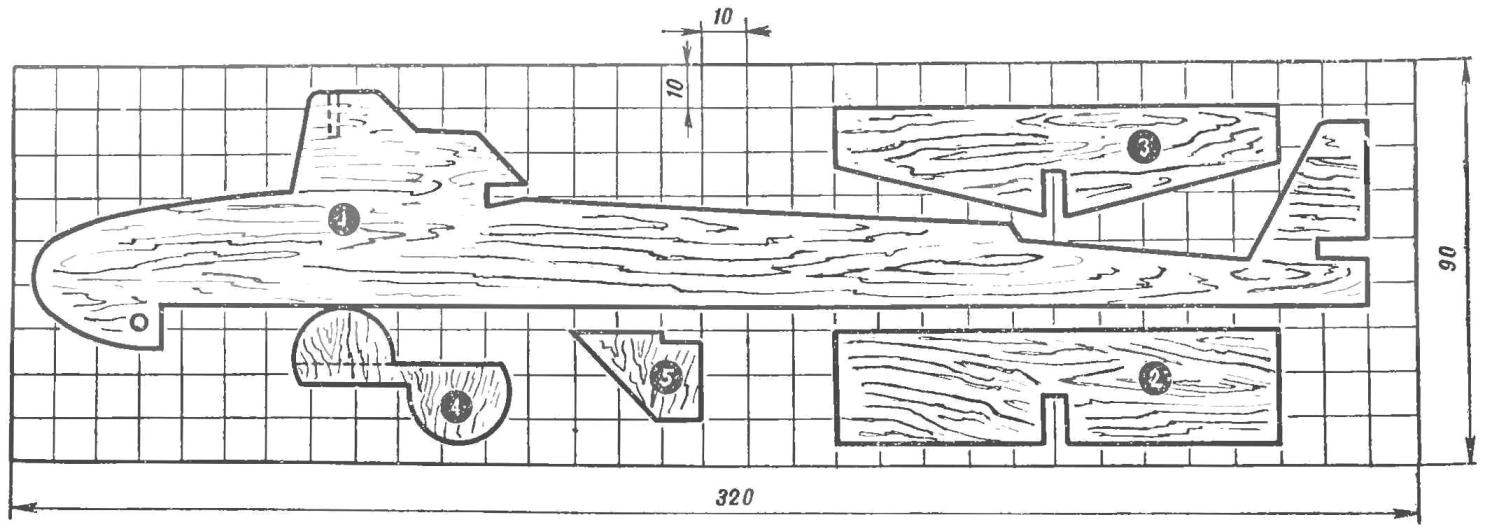

Do you want to build a model submarine? Start here with this most simple contour (see figure). She has much to teach the young shipwright: and how to manage the course of horizontal and vertical rudders, and acts like ballast, and how it works screw.

Do you want to build a model submarine? Start here with this most simple contour (see figure). She has much to teach the young shipwright: and how to manage the course of horizontal and vertical rudders, and acts like ballast, and how it works screw.

The model is cut with a jigsaw from plywood with thickness 3 — 5 mm, or from plates of the same thickness.

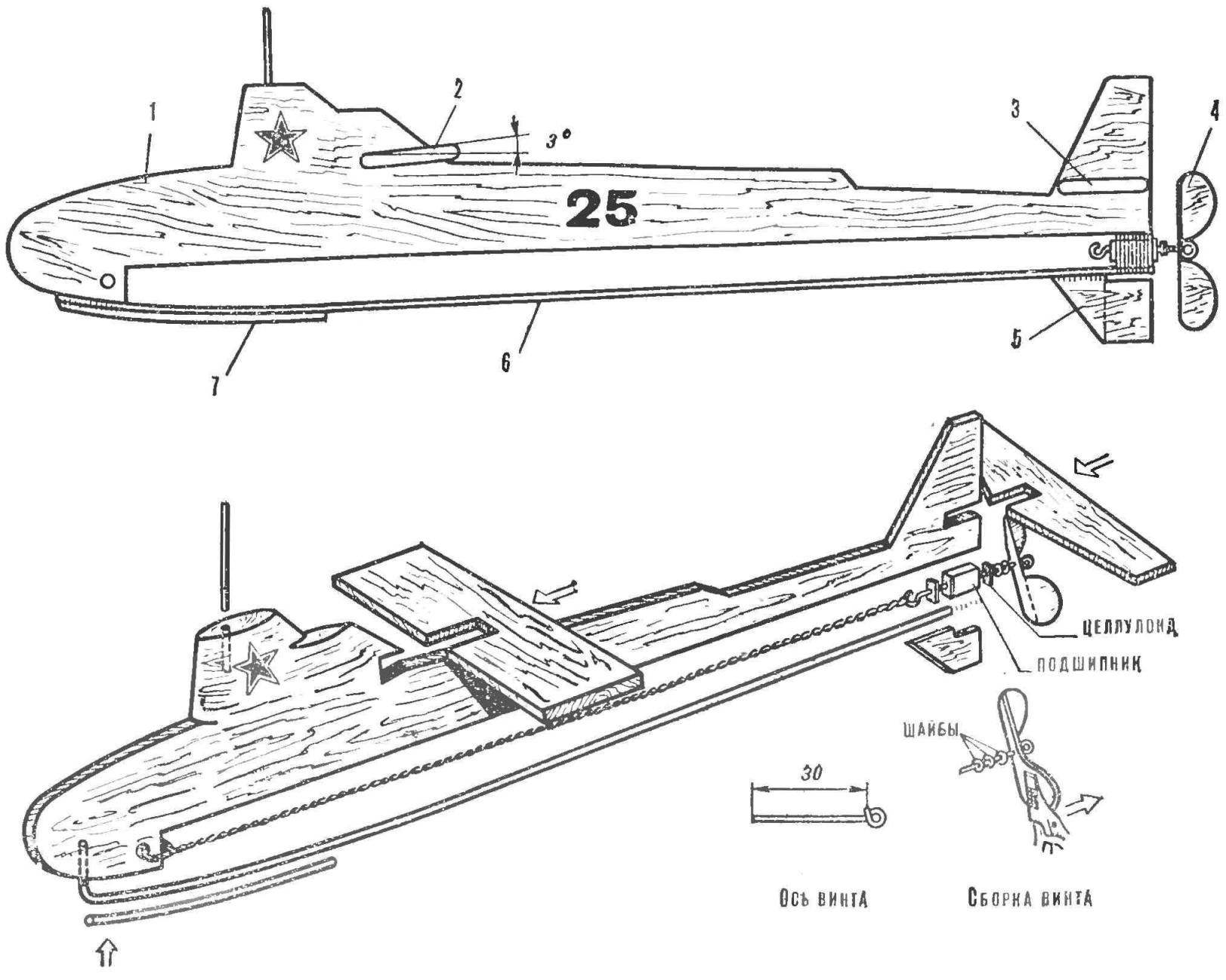

The hull of the boat and hydroplanes (3 aft, 2 fore) process with a file and sandpaper. Drilled holes for mounting the periscope, ballast, and rubber motor. The slots on the wheel and in the housing after propilivanija should be cleaned with a tip of a knife.

Handlebars — removable, mounted so that it was possible to change their setting angles during the adjustment and run the model.

Main ballast manufacture from wire Ø 1,5 mm. the Front part (7-10 mm| otogi perpendicular to up and tightly put in the bore of the body. Ballast back promail nitrocream and wrap the thread in one row turn to turn.

The bearing length of 10-12 mm is cut off from the rail section 10X6 mm Item processed an emery paper, cut two or three layers of glue and dry. Then primaty bearing to the ballast thread and attach both parts to the body. In the mid-bearing of a drilled hole with a diameter two times greater than the axis of the screw, and to its ends, stick a plate of celluloid size 10X4 mm hole for the axis of the propeller.

The axis of the screw make wire Ø 0.7 mm, the pattern of the screw and the vertical rudder from thin sheet metal.

The wheel prepay to the ballast and screw — axis. The ends of the blades are folded back with pliers on the lines indicated by dashed lines at 40-45°.

Gather the mechanism of the propeller. First axle, put two or three washers cut out of celluloid, they must be smooth and free to rotate. Then put the axle screw in the bearing bore, and its end with the pliers Sogni crochet. Check the smoothness of rotation of the screw. It needs to work easily and in the same plane, without wobbling.

Boat-diving:

1 — body, 2 — nasal horizontal steering wheel, 3 — aft horizontal wheel, 4 — prop, 5 — vertical steering wheel, 6 — core ballast, 7 — additional ballast.

Strengthen the periscope, prepay additional ballast wire Ø 1.5 mm and again treated surface of the boat with sandpaper fine grain.

The finished model is painted in bright colors, and then covered with nitrocellulose lacquer.

For motor need elastic thread with a length of about 540 mm. Insert one end in the housing bore, both ends tied in a knot and put the hook to the axis of the screw so that the knot was in front. The rubber motor should be slightly stretched.

Horizontal rudders set at a negative angle of 2-3°, grease axle screw and washer machine castor oil. You can run the model. If done correctly, it will sink into the water just before cutting. Now tighten the rubber motor by turning the screw clockwise 200-250 rpm. A well-made boat will smoothly enter the water and swim at a depth of 20-30 cm, will emerge with even a working propeller. If the boat is not immersed in water, the ballast needs to be increased.

Changing the angle of the horizontal rudders, bring different time of the manoeuvre. Ka fully wound rubber motor of a model must swim under water up to 20 m. the Deviation are eliminated by the vertical limb of the steering wheel in the opposite direction.

For winding the rubber motor, you can use the special handle (round stick) with a hook.

V. MATVEEV