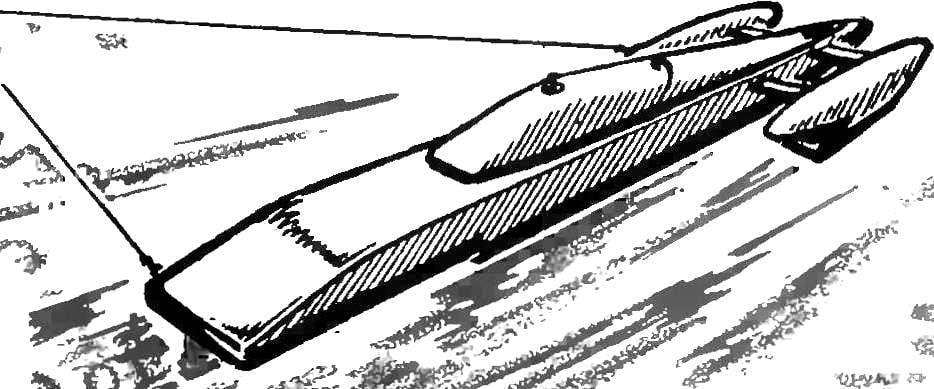

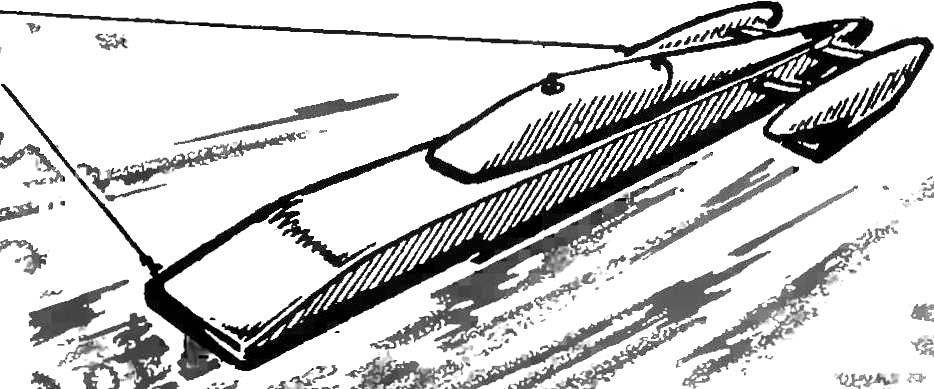

Fig. 1. Model glider with the propeller and the engine working volume of 2.5 cm3 :

1 — thruster, 2 — bracket of propeller shaft 3 — bearing housing 4 — taper-adapter, 5 — intermediate shaft 6 — deadwood, 7 — casing, 8 — the cross beam, 9 — float 10 — fairing, 11 — removable (movable part) cover-fairing, 12 — window approach to candle glow engine, 13 — feed the eyelet of the bridle, 14 — bow-ear bridle.

Fig. 2. The design of the model:

1 — thruster (Ø 35 — 40mm), 2 — bearing housing (steel tube Ø 7 mm), 3 — bracket (steel plate or profile area), 4 — cone adapter (steel, perform with hole and groove corner joint), 5 — feed boss (Linden), 6, 9, 24, 25, 26, 27, 34 — frames (plywood 1.5—2 mm), 7 — upper aft skin (lip thickness of 1.5 mm), 8, 23 — elements of the bottom of the sheathing (plywood 1.5 mm), 10 — side plating (lip thickness 1.5—2 mm), 11 — meghrashen lid lock matousek, 12, 40 power frames (plywood 3 mm), 13 — cover matousek (Linden or Vileika fiberglass), 14 — connecting tube (macrotermitinae rubber) with clamps, 15 — loop cover matousek, 16 resonance exhaust pipe, 17 — fairing (Linden) 18 — the bottom compartment of the tube (1 mm plywood), 19 — cross beam (D16T), 20 — node-socket fixing shank of the exhaust pipe (D16T, rubber), 21 — nasal boss (Linden), 22 — upper nose paneling (plywood 1.5 mm), 28 — side-chamber tube (1 mm plywood), 29 micromotor (glow, working volume of 2.5 cm3), 30 — beam engine mounts (hornbeam), 31 — a flywheel 32 — nut of the flywheel, it — the joint housing (steel), 33 — pipe deadwood (brass), 35 — wall side of the fuel tank (plywood 1 mm), 36 — bearing deadwood (brass, PTFE), a 37 — intermediate propeller shaft (wire-Serebryanka), 38 fuel tank, 39 — supply pipe of the engine.

Power circuit is formed by a box-like housing. As shown, at first, when the Modeler is not formed skills of working with different materials and tools, such construction is most accessible to manufacture and provides good results in strength and mass. -Body dyblenko possible only more experienced. By the way, and the gain in mass obtained in this type of buildings, not so great. And contrary to popular belief, the meaning of sorgoleone speed boat is not too much. Of course, the dependence of the hydrodynamic losses of the mass of the vessel remains in force. But in the real conditions of the race, when the point of suspension cords of the Central riser located high enough above the water level, the possible situation in which the achievement of even a not too high speed, there was complete unloading of the sponsons. Details with this effect you can see after reading the article by G. Shahazizyan in the “M-K” No. 2, 1987. By the way, it is appropriate to recall the models with the propeller, or rather aerodynamic the wings, the stabilizers, capable of pressing a certain part of the model to the water!

Fig. 3. Float:

1 — float case (lime-tree, to facilitate the chiselling to a wall thickness of about 1-1. 5 mm), 2 — “stand” (Linden), 3 — frame (plywood 1.5 mm), 4 — cross beam (area of bonding to clean up, degrease with acetone, wrap cotton thread), 5 — sole of the redan (aluminum foil thickness of 0.1 mm).

Fig. 4. The flywheel (brass — compression engine, made of anodized aluminum for nitro).

So, body-box. In the figures it presented in the most accessible variant — in the form of carrier panels made of fake plates and connected by means of a set of frames. Please note — the bottom of this case is made of plywood. As a result, possible to achieve high strength and stiffness, resistance to cracking in the layers of wood while reducing “holosystolic” wooden box. After all, most “sounding” plywood sheathing underneath. The extra muffling of sound, that becomes an important issue when using uprated powerful engines, can be achieved by sealing all the cavities of the housing blocks of foam (a variant of the design of the hull out of foam with a thin bearing shell-covering beginners to not recommend, because of possible flaws in the work here significantly affect the loss in strength and mass gain). If possible, the same case-box wikiepedia not from lime and balsa plates. The use of light wood though, and will require specific techniques in the surface finish, still more advantageous from the point of view of noise. The thickness of a covering from balsa is better to increase two times in comparison with lime. But due to the impregnation with glue, and weighted the outer finishing layer, the total prize mass will be small.

Housing lead to a phase preceding the installation of the last, the top of skin. Before gluing the foam inserts that have to be joined tightly to all surfaces of the boards, it is necessary to impregnate the entire body is liquefied from the inside with alcohol two-component parquet lacquer for protection from moisture and to check the connectivity of the elements of the propulsion system with the frame of the glider. As the proposed model, the fuel tank is mounted without the possibility of subsequent replacement, we encourage you to monitor its performance both from the point of view of quality of performance, and in relation to a particular motor unit and this type of fuel delivery to the carb. In some cases, when the system power fuel cannot be considered as proven or model you plan to install different types of motors, compartment of the tank must be easily accessible. Then you need to increase the rear part of the cover-fairing and… to deal with reduced strength model in the jet area. To partially compensate for the weakening will be due to the lengthening of the tail parts motor bars. When you open the compartment of the tank hornbeam details should reach the frame which in this embodiment will begin aft upper removable trim panel.

Other details hydroplane special explanation is not required. The front location of the resonance of the exhaust pipe have already been tested on such devices, and in the present embodiment, the window exhaust emissions are additionally protected due to the buoyancy of the floats. Not shown on drawings Windows for inlet and outlet of cooling air of the engine. They are cut in the lid of the spinner and the stationary part of the fairing to simultaneously secure and reliable mode of the motor, and minimize sound vibrations that penetrate outward through the window. Some help in sound attenuation can provide light, guides the air flow deflectors. They are stuck inside the fairing, blocking the path of sound vibrations. And from having large holes for the starter strap allows you to get the design legkoatletichesky cover matousek.

The basic data model

Overall length, mm: 730

Width, mm: 180

Weight, g: 700-800

V. ILYASHENKO, A. DARA

Recommend to read WHEN TALENT ALONE IS NOT ENOUGH We left two outstanding inventors, John Holland and Edmund Zelinskogo, in 1886 in a pretty sad state. The firm of submarines collapsed simultaneously with the physical collapse of the... BUTT? IT’S EASY! Dear editors! Send a description of simple tools that may be needed in the manufacture of furniture Think it will appeal to many I have it used successfully for years. In the...  What is to be the new model? This question with relentless regularity occurs before each athlete, the venerable and the very young, immediately after the end of the season. The stage selection scheme of another apparatus is extremely “delicious” for any designer-Modeler, but also time-consuming and responsible. It is here laid the foundations of sporting success at future competitions.

What is to be the new model? This question with relentless regularity occurs before each athlete, the venerable and the very young, immediately after the end of the season. The stage selection scheme of another apparatus is extremely “delicious” for any designer-Modeler, but also time-consuming and responsible. It is here laid the foundations of sporting success at future competitions.