The second model is also of noble birth, a native of England. Designed to participate in the competition in the class “polutorametrovoy” (corresponding to the domestic division of school models) and are designed for serial compression engine is very limited power. Design alnobetula. Power front edge of the permanent Secunia 18×18 mm, rear — mm. 4×18 Typical intermediate rib, the elements of the wingtips, fairings trailing edge — wood, 3 mm thick veneer cut From chetyrehkilometrovoy basal and a pair of glued together blanks for the root rib and the Elevator and adjacent the rear edge. On top of the assembled frame of the Central rib is sheathed top and bottom curved clip polutorametrovoy of plywood that connects the middle area into a single rugged unit. As the first model tank hard top, soldered tin. Rocking the management of the PCB is mounted on plate bracket (plywood 3 mm), the conclusions of the wires shifted back. Engine mount formed by the Assembly of polutorametrovoy veneer inlays, two bars motor of beech cross section of 9×9 mm and balsa “cowl” with a thickness of 9 mm. the Covering model — brand film, the characteristics are roughly equivalent to the domestic Dacron with a thickness of 0.02—0.025 mm. the center section of the frame to enhance can additionally obthayutsya thin kapron TANU. It is useful to pay attention to the angle of the needle guard the needle valve, hold the legs above the crankcase During operation of the engine with front-wheel distribution this simple detail will help to keep Inler

in all situations. The airfoil of the type “plate” has a thickness of 18 mm.

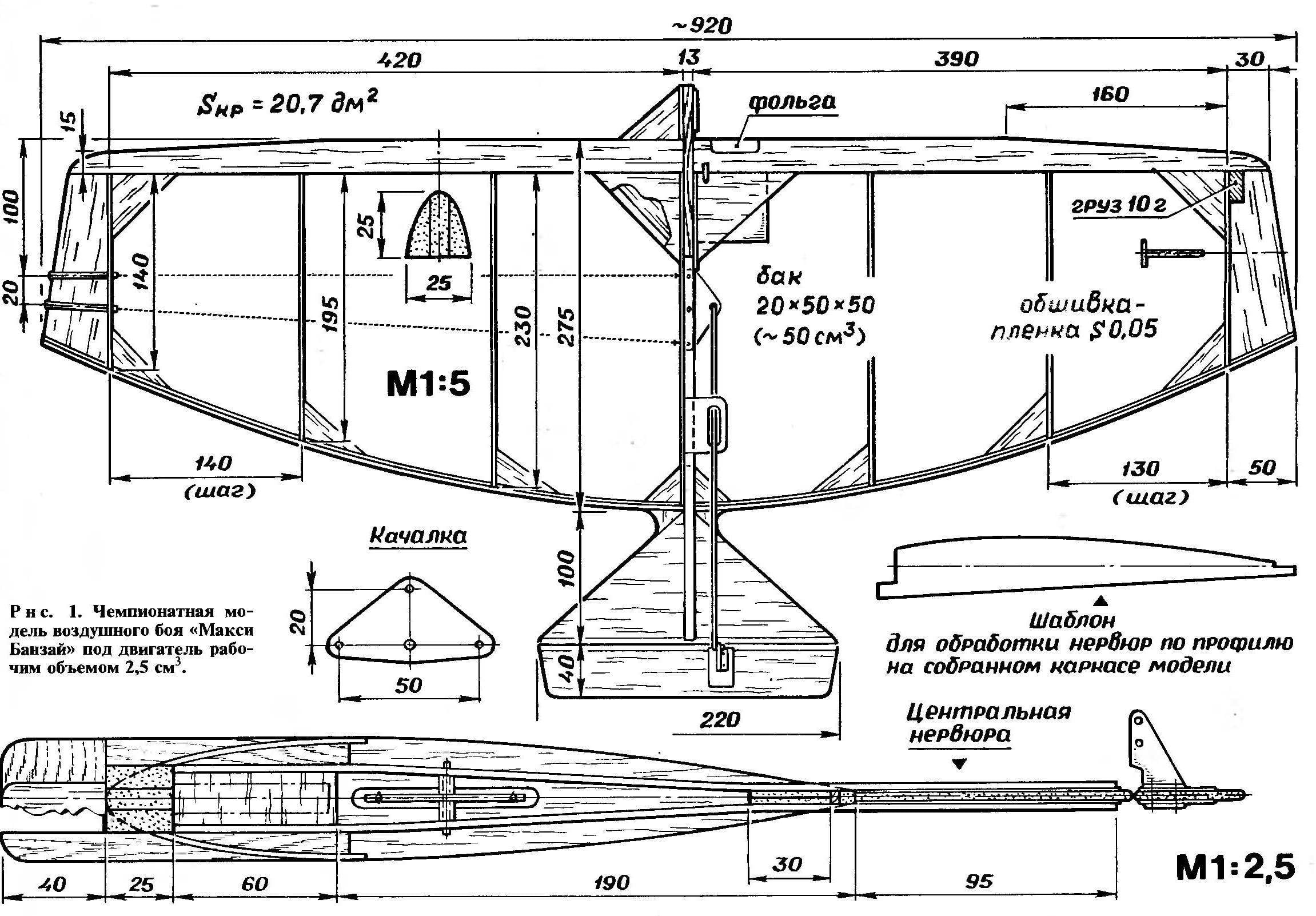

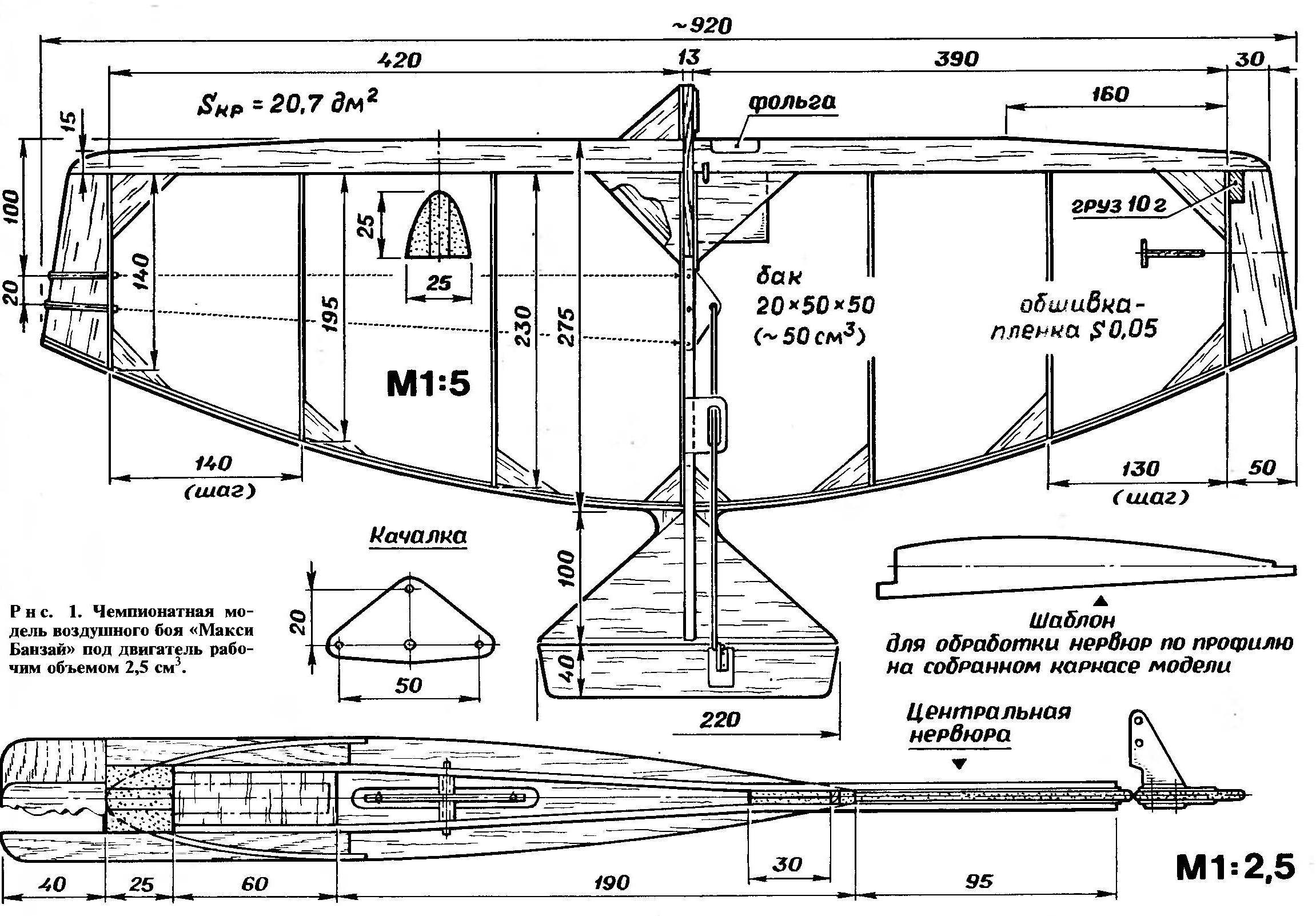

The third model of air combat — domestic developments. Spoeksman on it under the obvious influence of frame “odnoprovodnoi” scheme, promoted by the magazine “modelist-Konstruktor” and not found in other publications for modelers. The main characteristics of this concept — basing on domestic materials, the maximum design simplicity, to take into account such important factors as the moment of inertia of the model relative to the axis of rotation maneuver and the effect of the elastic wing (sorry, in lack of mo^ appreciated by athletes). Power front edge (ellipse section, with a height of 11 mm and a length along the chord 17 mm) to both ends of the wing has polutorakratnogo reduction section. The Central reinforcement of the edges is used in order to give the opportunity to push a relatively heavy engine in the wing. If the tail of bouzouki such an event reduces the moment of inertia of the model at a constant alignment. The result benefits not only the nature of control and maneuverability in General. The cross section of the reinforcement insert 11 x 14 mm. the Material is the same as that of the edges and all other parts of the model,— pine-medium density, but higher quality (grained, without ROE). The trailing edge section 4×14 mm should be made of pine, the horizontal arrangement of annual layers. The intermediate ribs have a cross-section of 4×16 mm ending — 9×11 …12 mm (the last dimension is height). The Central rib is represented by beam cross-section 9×18 mm. Gusset plate is sawn from plywood with a thickness of 2.5…3 mm. the Entire Assembly is carried out by Strait benevolence seams fresh plasticized epoxy resin. Avoid the use of scarce mm plywood even in the area of motor managed by the two pairs of wedge-shaped plates rigidly connecting the Central rib with the force edge. The engine is hung on the most modern system — at the corners, screwed n the rear wall of the housing and the bracket on the cylinder head Such a scheme not only reduces mass of the model, but also reduces the moment of inertia. After profiling of the wing (by the way, as noted, is more useful when lapping the front edge to the cross section closer to the triangle than n times, although ideally it requires proper palealis) and it stitched the captive medium, or the increased thickness of the space under the hinge of the engine are cleaned up, they are the boss of beech wood or thick plywood, and through the whole “sandwich” is sealed with filament winding a steel pipe under the main bolt of the engine. The Elevator is an arbitrary design but with the minimum mass. Here, given the over-chemomentum of inertia it is useful to know that the relief helm on 5 g gives the same result as the removal of 20 with the rear edge! You can also make another conclusion: dramatically easier and stabilizer nodes can be, for example, not to trifle with the cross-section of the trailing edge (excluding the Central nodes of the junction) and of all other parts located near the center line of gravity. The long massive engine KMD-2.5 allowed beam design of the whole control system it loss the moment of inertia is largely kompensiruet increase the effectiveness of all-moving tail. Centering the load on the outer end of the wing is shifted towards the leading edge, which significantly improves the nature of the input and output of the model in forward and reverse maneuvers. The thickness of the wing in the center, 18 mm. it Should be noted that the “odnoprovodnoi” scheme, this frame size does not make much sense, as the overwhelming area of the real thickness profile of the given film and facing Naga a lot less. If desired, instead of one intermediate rib, each console can be set at two, while increasing the profile thickness up to 25…35 mm, and going to the ribs on the plywood thickness 2.5 mm. 3…Also from plywood or pine strips are made and extensions of the Central rib-beam ‘ cross-section which is allowable in this embodiment to reduce up to 9×11 mm. However, similar experiments with pereprofilirovanie should be treated with caution. In some cases, this can give not only a reduction of speed, but maneuverability is directly associated with the flexibility of a framework for the scope and flexibility of a film of plating.

In the initial embodiment portenoy the frame of the wing of the type proposed with built-in tank, control system and the load on the end of the wing has a mass of 180 to 200 g. it has to be noted that when the limited power of the engine is not worth chasing… sorgoleone model. Oddly enough, it is. When “decheniana” flight speeds lightweight, for example, to 100 g of models of air combat maneuvering, but absolutely unreliable in the sense of the tension cord and control not only when a sharp gust of wind, but even in some of the series of figures, accompanied by a decrease of speed. Therefore, when the area of the wing about 20 dm2 weight bouzouki в400 g admittedly optimal. The reliability factor of the tension cord is so important that sometimes leads to paradoxical results in a class “polutorachasovom” — there are cases when only for reasons of manageability had to reload very good for aerodynamics and strength of a small car! And therefore the choice of optimum load-bearing area must be treated carefully as possible, taking into account not only the engine power, but all the other factors.

To help the designer of new bizovac, we offer a detailed strength analysis of the bearing element, power front monochrome. Factor introduced into the calculation of the bending moment is derived as the average. It is obtained based on processing all available materials on known good machines and takes into account the distribution and concentration of mass along the span. We recommend to use the given calculation across all instances of the use of monochrome, especially when creating a new-fangled flexible frames.

V. KIBETS,

CCTBM engineer, group leader

Today we offer air fighters rather unusual material. It to modelers “mediocre” are not only good examples of several design developments that can be used to practice aerial combat, but based on them the basic principles of the calculation and creation of new machines. We hope that the theoretical part of the material will be even more useful than pure information: it will help not only in understanding the strengths and weaknesses of existing models, but also in the design of bizovac new types.

Today we offer air fighters rather unusual material. It to modelers “mediocre” are not only good examples of several design developments that can be used to practice aerial combat, but based on them the basic principles of the calculation and creation of new machines. We hope that the theoretical part of the material will be even more useful than pure information: it will help not only in understanding the strengths and weaknesses of existing models, but also in the design of bizovac new types.