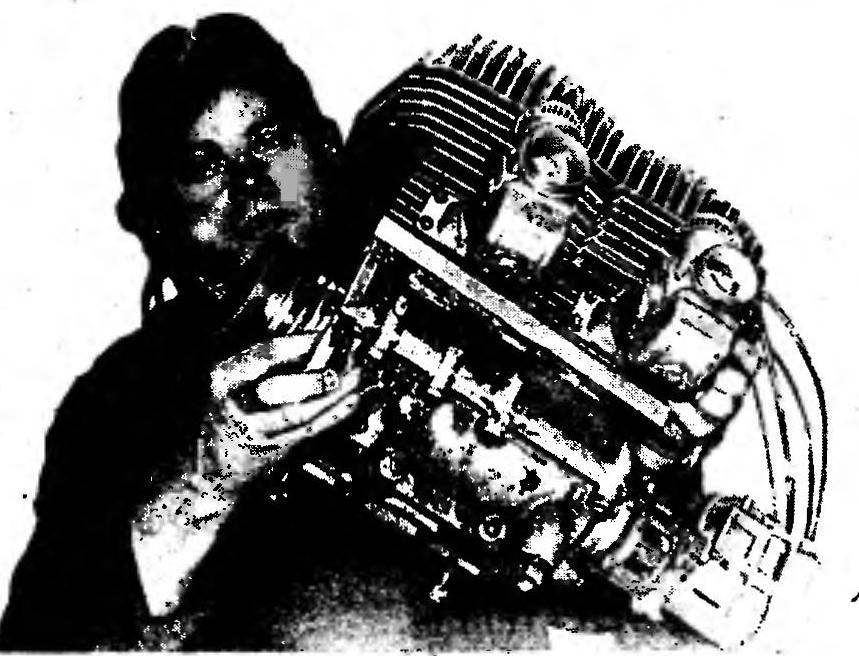

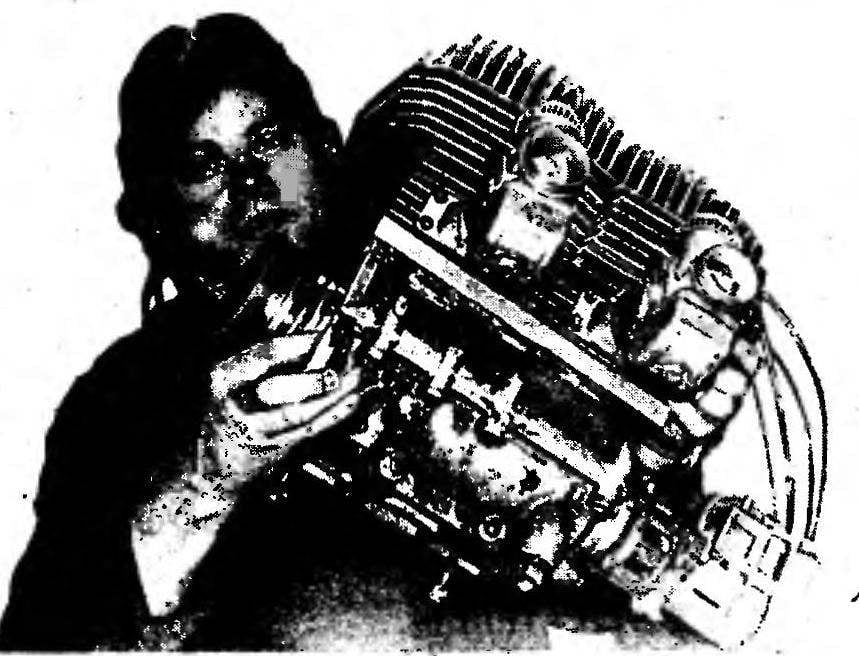

Numerous rallies of Amateur aircraft collected hundreds of enthusiasts, small aircraft, and it clearly showed that the interest in the design of Amateur aircraft huge. However, in many cases an unsolvable problem for fans of the SLA is the issue of motor—powerful, light, compact and economical. I believe that if the industry produced similar engines, small aircraft in Russia would have developed much more rapidly. In the meantime, the only way to saadeldin remains the manufacture of such a motor with his own hands.

Offer aviation enthusiasts the experience of manufacturing this kind of engine, which are concentrated and the joys of success and bitter disappointment, besides, and a lot of time and material resources.

I want to warn that I developed an engine is not a something new — it’s just good development on the existing engines, proven in the course of long practice.

I would like to mention also that many homebrew deterred by the apparent complexity of creating such units as the aircraft engine. I can assure you that the engine type “KOMPAKT-800” can build almost any designer-lover, with plumbing skills. And, of course, an optimal set of component elements on the basis of which and going to digital. In particular, it is necessary imvt fire pump MP-800 (suitable even worthless, decommissioned), two crankshaft and two cylinders from a motorcycle “IZH-Planeta-Sport” (hereinafter —IL-P-s), two carb “ICA-34 or ICA-36” with a set of nozzles from a sports bike CZ-400 (suitable FOR domestic-62M from IZH-P-s) and two piston diameter of 82 mm with rings from motorcycle CZ:400.

A few words about the technical characteristics of the engine “CD 800”. This inline two-cylinder two-stroke air cooled motor with a weight of 37.6 kg (without carburetors and system seigaku) has a working volume of 600 CC, bore 82 mm, stroke is 76 mm and the compression ratio of 10.7. Engine power 70 HP at the engine speed 5900…6100 1/min. Fuel — gasoline a-93 mixed with 5% oil MS-20. Exhaust using two tuned resonators.

The original cylinders bored to the diameter of 62 mm at the pistons from CZ-400. When assembled adjacent to each other part of the heads and fins of the cylinders frezeruyutsya so that the distance to the plane of the milling from the axis of the cylinder was 72

To prevent turbulence of the flow of air-fuel mixture in the engine cylinders and improving their purge large sphere cylinder must be processed on a lathe (four jaw Chuck) along the radius of the piston, and the head diameter is smoothly reduced to the diameter of 82 mm. the Required degree of compression is selected with the pad of desired thickness, installed between the crankcase and the cylinder.

The crankshaft from the motor-pump MP-800, consisting of two cranks with collet-type connection in the penultimate cheek of the crankshaft (magneto side), easy to disassemble without damaging the cheeks of the shaft. Notice that the connecting rod of the engine pump does not match the corresponding PA: the parameters have the IZH-P-s (85 and 76 mm, respectively). That is why in the cheeks disassembled crankshaft regular axles are cut and their openings zapressovyvajutsja (fit — a tense press) new axles from steel 40X, with allowance for further processing under the landing bearings. The old holes of the lower connecting rod fingers gently brewed, and without porosities and foreign clucene. New holes for the lower connecting rod finger IZH-P-s is cut at a distance of 38 mm from the center cheeks of the crankshaft. Both halves of the shaft are built separately, and alternately processed in the lathe.

Fig. 1. Compact two-cylinder aviation engine, “CD-800”:

1 — cylinder, 2 — cylinder, 3 — ‘gasket set, 4 — rear axle crankshaft (standard), 5 — a glass seal 6 — roller bearing 2306К, 7 — tightening bolt detachable parts crank shaft 8 — thrust washer, 9, 11 — ball bearings 306К, 10 — mikamura spacer with gaskets, 12 — lower connecting rod, the finger 13 — a crankcase, 14 — front axle crankshaft, 15 — front glass seal, 16 — thrust bearing 8207, 17 — roller bearing 42207К, 18-channel for lubricant, 19 — cheek of the crankshaft 20 spacer between the crankcase and cylinders, 21 — rod 22 — piston pin 23 — needle bearing upper head of connecting rod 24, a piston with two rings.

Fig. 2. Speed stud cylinder mounting.

Fig. 3. Bolt with socket head (for mounting spacers).

R and S. 4. Long hairpin.

R and S. 5. Prostats.

Fig. b. The resonant exhaust pipe under the frequency of rotation of a cranked shaft…5800 6100 1/min.

The assembled shaft is balanced on the fence Assembly with pistons, piston rings and fingers. The difference between the sets of cylinders should be no more than 2-3 g, or cases to avoid excessive vibration of the engine. Debugging when balancing the crankshaft is carried out by drilling holes in the cheeks.

The connecting rods, the upper and lower toes separators were used from the engine of IZH-P-P Pistons with two rings ensure minimum friction of the cylinder pair and the reliability of the motor.

The crankcase — from the already repeatedly mentioned pumps, but the upper half is partially modified. The fact that the height of the bottom of the piston СZ-400 6 mm less than the IZH-P-s, so from the surface of the upper crankcase cover must be removed 4 mm and bring the mating plane on pridorozhnoy plate. It is also necessary to reduce the height of the cylinder: on a lathe to cut 2 mm of its flange.

In addition, between the upper half of crankcase and cylinders, you must install the cast aluminum spacer, which cut the holes in the cylinder liners and the bypass channels, and a threaded hole M10x1 mm for the four fixing studs of the cylinders on the combined templates, removed from the cylinders and crankcase. In the “CD-800” thickness prostate parasitemie together with two spacers with a thickness of 0.5 mm is 20 mm.

Before the boring and fine-tuning of the upper crankcase cover on her tie-rods fixed to the spacer. Next, with the same setup in the cap and the spacer chiseled the holes for the cylinder sleeves to a diameter of 66 mm to a depth of 24 mm. unfortunately, to complete work on the fit of the cylinders into the crankcase (to a depth of 6 mm) using a machine will fail due to the fact that in the crankcase in the area of side-overflow Windows, possible perforation. Therefore, the cylinders are finally fitted to the crankcase by means of manual processing. Manual selection of the metal and subsequent polishing of the inevitable and the processing of the crankcase cover smooth contours passageways. While it is most convenient to focus on the standard, which can take the old Carter motor IZH-P-S.

In the manufacture of the crankcase, good help can be argon Duguay welding: with welding metal to eliminate perforation: weld metal layer in the area of the overflow channel in the case that the perforation is inevitable.

When assembling the crankcase crankshaft should be borne in mind that the cylinders of the engine operate out of phase, and the cavity of the crank chambers of the engine must be isolated from each other and not have the bypass pressure. To this end, the cameras mounted regular spacer with embedded in it the two seals.

When assembling the engine into the crankcase of the motor natugo are rolled four speed studs (each welded section of the two rods with M10 threaded hole at one end), oriented in such a way as to provide a loose fit on the crankcase, cylinders with heads. Further, through paronitovye the gasket on the crankcase by means of bolts with cylindrical heads “wpoty” fixed spacer, and cut it the threaded holes are rolled M10x1 long studs, then mounted the cylinders with the heads and are fixed with nuts placed under them washers. Pre-intercostal bridge on the cylinder should be removed — it will improve engine cooling.

It should be noted that “CD-800” develops, as indicated above, the power when working with tuned resonant exhaust pipes, the optimum geometrical dimensions of which are shown on one of the drawings.

The regular ignition system based on the magneto to the aircraft engine, because a stable and sustainable spark magneto can guarantee at significantly lower RPMs than the that develops the “CD 800”. That is why it uses a 12-volt ignition system of the motorcycle “Jawa”. The parameters of the ignition system (advance, the gap between the breaker contacts) for each cylinder are set as double — cylinder motorcycle- separately for each cylinder.

Note that for aircraft engine it is desirable to have dohistory ignition system (with a couple of candles on the cylinder), providing the delay of the appearance of sparks on one of the candles in 4…6 degrees of crankshaft rotation. Of course, ispolzovnii dvuhkrugovogo ignition energy for each spark of the cylinder should be Autonomous.

I want to warn enthusiasts, trying to whatever was to increase the power of any fall into their hands motor that all reasonable measures for this purpose “CD-800” was already taken, and further the force of the engine can lead to a sharp decline of the resource. In particular, gone to the optimum mean effective pressure in the cylinder: 6.5 kg/sq cm Ultimate and most beneficial for optimally stable operation of the motor can be called the degree of compression is at 9.5 to 10.7…. I must say that the power “CD-800” is more than enough for most Amateur aircraft. Here are just a few of the digital characteristics, showing the capabilities of my motor. So, at bench trials, the peripheral speed of the ends of the blades a four-foot propeller has reached 240 m/s. Static thrust in this case was 160 kg, and the efficiency of the propeller 67%!

Questions about the design email me at: 624470, Sverdlovsk region, Severouralsk St. Komsomolskaya, house 37, apartment 115.

V. DUBROVIN

Recommend to read “WASHEE-WASHEE” ON THE SIDEWALK In Moscow in the yard of the house № 11 on the 2nd Schukinskaya travel can often see the most incredible car designs, which are operated by boys and girls. And the amazing thing is that... NOT CLOGGED Often in life there is a need to carefully pour some liquid from one vessel to another so as not to affect sediment on the bottom. Usually use the suction tube. But it is necessary to... Scroll back to top