The ENGINE from the car “Moskvich-412” is installed on the brackets of the frame at its native pillows. For a more uniform transverse is scoops it is shifted to the right by 50 mm (this is evident in the configuration of the brackets of the frame). The shift resulted in a shift of the same distance to the right of the gearbox and also revealed the need to manufacture it under steel beams.

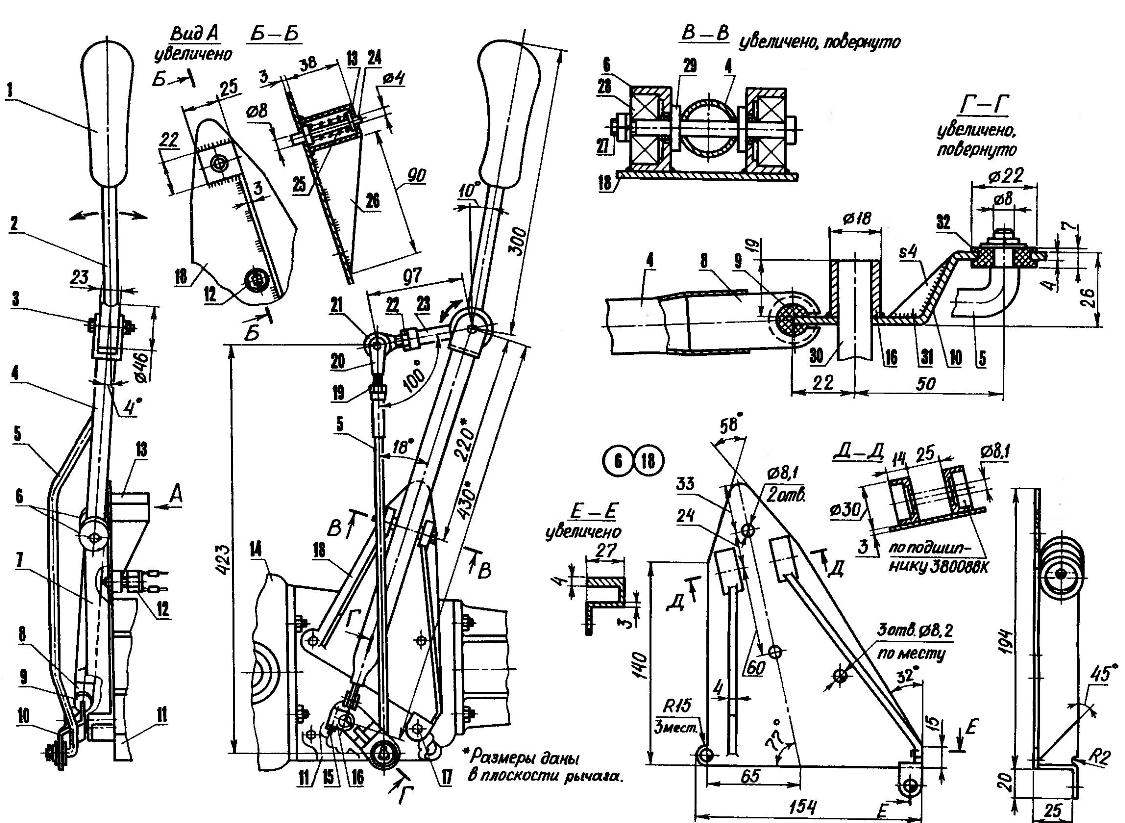

Since the outer gear “moskovichevskoe” the checkpoint is a collection of more than twenty levers and moving parts, Stanislav decided to replace it with a more simple and reliable homemade. The new mechanism consists of just a few hinged parts.

Triangular mast new mechanism attached to the left side of the transmission with three screws M8. On the left of the carriage is attached (pivotally) of the intermediate lever, and on the right (hard) — limit switch for reversing light spring and a damper, softening of the transverse stroke of the lever.

The gearshift transmission-equipped Z-shaped leash, the end of which is connected with a long rod passing through the floor in the cabin of the car. There link is connected with a plow shift lever, swinging on the upper end of the intermediate lever. The feather is welded to the lower end of the lever has a slot under the Teflon liner, placed

radius the edge of the leash. Thus, the lever for choosing the appropriate transmission without interference moves the rod along its axis in any position of the leash. The author himself used this mechanism and found it works perfectly!

FRONT AXLE with a powerful beam from the car “Volga” GAZ-24. However, the intention of Stanislaus to use the “moskovichevskoe” wheels combined with wheel hubs and steering knuckles demanded the replacement of certain elements “volgovskoe” front suspensions. In particular, instead of racks with their hinges and pins on the upper and lower control arms were installed adapters with ball joints “Moskvich-412” instead of rubber bushings — a more modern “Zhiguli” silent blocks instead of rubber Hooke — a more robust universal joint.

To the vehicle frame beam front axle attached to the regular eyelets and four bolts (for these purposes, the mounting holes of the corresponding frame welded sleeve).

Right-bearing external trunk (right side from inside body):

1 — arm security body (steel pipe 20×2, 3 pieces); 2 — saddle (3). 3 — the support of the trunk (pipe 25×2, sheet s2); 4 — the roof of the body; 5 — bolt M8 (6 PCs); 6 — bracket arcs (area 32x32x1,5, 3). 7 — side pillar

Cross member under the gearbox (rear view):

1 — plate (steel, sheet s3, 2 PCs); 2 — yoke (steel, sheet s3); 3 — solitaire (steel, sheet s3, 4 pieces); 4 — rubber bushings (4 PCs.)

Modified front under good:

1 — upper and lower wishbones (from GAZ-24 “Volga”); 2 — adapter; 3 — upper and lower ball joints (from the “Moskvich-412”); 4 — paws knuckle

The intermediate shaft rocking:

1 — protective cap (from the wheel “Moscow-cha-412”); 2 — Welt nut M20; 3 — bearing 7204 (2); 4 — housing; 5 cuff 1-32×52

STEERING. In his design applied to a circuit of a steering trapeze with intermediate rocking as the car “RAF”, “Sobol”, “Barguzin”. The rocking shaft is machined from a spare steering shaft “Volga” GAZ-24, and the hull is in one chiseled detail and three eyelet fastening to Cristano frame. The upper rocking shaft bearing is protected from dirt by a cap, which is covered by axle “moskovichevskoe” wheels, and the lower rubber bellow.

Steering:

1 — steering column (from the “Ford Escort”); 2 — steering; 3,4— longitudinal and transverse thrust; 5 — axle housing intermediate rocking; 6— intermediate rocking; 7,10 — steering traction wheels; 8 — steering gear (GAZ-24); 9 — a Pitman arm

REAR AXLE, as already noted, the entire from of the car “Moskvich-412”. Because the track of the “ASKO-RA” more “moskovichevskoe”, the bridge needed to be lengthened. So, make a new axle. To save at least one of them, the designer decided to extend Carter (“stocking”) of only the left axis, given that due to the displacement of the engine to the right still need to move after him and the main transmission.

Modified Carter left rear axle shaft:

1 —long “stocking”; 2—the reference site spring; 3 — extension coupling (steel, pipe 65×2,5); 4 — elektroskripka d8 (2×10 pieces)

Front mount spring:

1 — shaped bolt M12x1,25; 2,6 — cheeks clamp springs; 3,5 — rubber grommet (from GAZ-24); 4 — bar spring; 7 — washer; 8 — Welt nut M12x1,25

Stanislav sawed “stocking” an ordinary hacksaw, departing 50 mm from the support ploshadka spring in the direction of the main gear, put on the section of the extension coupling from the pipe of suitable diameter, inserted in the “stocking” a new half shaft, pre-machined axle of the car GAZ-51, and scald the ends of the coupling. And that connection was more durable, strengthened its so-called plug lap joint, nasverliv in a circle in two places extension couplers ten blind holes and brew them.

FUEL TANK capacity of 80 HP two internal partitions (so fuel is not a particularly lapped and sharply did not change the alignment of the machine) is a homemade, welded from steel sheet of thickness 0.8 mm. the level Sensor and the intake of fuel — from the “Niva” VAZ-2121. Is the tank underneath the car behind the rear axle.

Fuel tank:

1 — body (steel, sheet s,8); 2,4 — bulkhead (steel, sheet s0,8); 3 — hole under the drain plug; 5 — drain pipe (steel pipe 12×1, L60); 6 — hole podzabornik the fuel level sensor (atwas-2121); 7 — filler neck (steel pipe 45×1,5, L60)

BUMPERS. The front is similar to the “mos-cwikowski” (AZLK-2141), and back — on “Zhiguli” (VAZ-2105). However, this is only the external similarity. Actually both bumpers homemade, laminated of fiberglass and epoxy resin on wooden dummies.

Outer gear:

1 — knob 2 — handle shifter (steel pipe 14×1,5); 3,27 — bolts M8; 4 — an intermediate lever (steel, pipe 20×1,5); 5 — thrust (steel, rod d10), b — fulcrum of the lever; 7 — the rib of the carriage (steel, strip s4); 8 — pen arm (steel, sheet s5); 9 — liner (PTFE); 10 — lead (steel, sheet s4); 11 — CAT; 12 — limit switch for reversing light; 13 — the case of the damper (steel, sheet s1); 14 — clutch housing; 15 — conical bolt-retainer M8; 16 — bushing-latch; 17 — screw M8 mounting carriage (3).

18—carriage (welded Assembly); 19—lock nut M8; 20 — rod tip; 21 — tip of the Pitman arm (the aviation tip with SS-8 and M10 thread); 22 — lock nut M10; 23 — fry (steel pipe 14×1,5); 24 — rod damper; 25 — spring damper d10; 26 — stiffener damper (steel, sheet s3); 28 — 380088К bearing (2 PCs.) 29 — washer (2 PCs); 30 — a gearshift transmission; 31 — rib of the leash (steel, sheet s4); 32 — rocker bushing (from the “Moskvich-412”)

A. TIMCHENKO