The surface thus prepared housing eskoriatza, in the foam filling cut two notches (less under steering car, more under the receiver remote control equipment and batteries), which are pasted plywood (thickness 3 mm) base for mounting components of the apparatus.

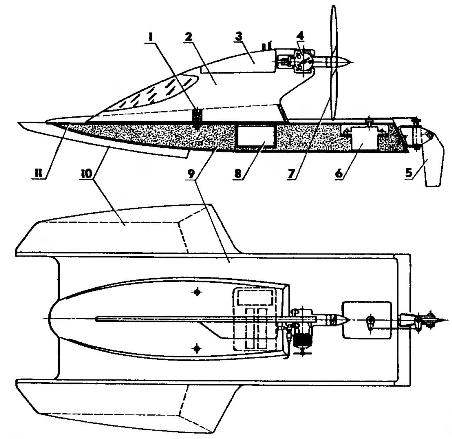

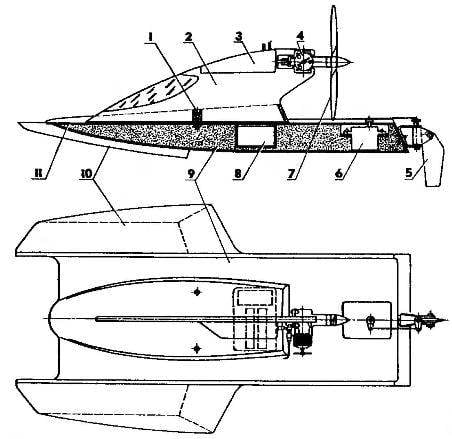

The Central part of the body:

1 — side panel (plywood or fake wood veneer s1); 2 — filling (packing foam); 3 — transom (plywood s3); 4,8 — stringers (pine, battens 3×3); 5 — base of the steering machine (plywood s3); 6— base of the receiver and the battery unit; 7—bottom plate (veneer or fake veneer s1)

Lateral float:

1 — trim the cheekbones (veneer or fake veneer s1); 2 — filling (packing foam); 3 — the bottom (veneer or fake veneer s1); 4 — stringers (pine, battens 3×3)

Fuel tank:

1 — bottom cover (sheet s0,3); 2 — M3 screw fixing the tank to the pylon (soldered to the pot); 3 — top cover of the tank (plate s0,3); 4 — shell (tin s0,3); 5 — fitting of the fuel (silicon tube); 6 — filling nozzle (copper, tube 3×0,5); 7— drain fitting (copper tube 3×0,5); 8 — fitting (copper tube 3×0,5)

Steering gear:

1 — M3 nut fixing steering arm; 2 — bracket (D16T, sheet s2); 3 — washer; 4 — axle balleroy carton (M3 bolt); 5 — steering pen (D16T, sheet s3); 6 — ballerina box (vinyl plastic or PCB); 7 — axle steering pen (M3 screw with two nuts); 8 — steering arm (D16T, sheet s2); 9 — spring-brace

Further, the Central part of the body is glued to a plywood base plate element, after which on the same technology — with the use of foam blanks, pine stringers and sheathing of plywood or veneer — made two side of the float. The latter are attached to the Central element of the housing and the base plate also with epoxy glue.

The engine pylon is cut out of 10 mm plywood and, if necessary, easier — there are cut holes, after which the pylon is glued on both sides 1 mm plywood. In front of the pylon there is a cut after painting the model it on the glue is inserted into the glazing of any transparent plastic. Next to the pylon to fasten the two tie bar: the rear of the 8-mm plywood and birch front plate thickness of 12 mm, and the space between the cross members is filled with foam. The surface of the resulting superstructure is aligned and glued a thin glass fiber epoxy resin.

Fuel tank capacity of about 60 ml of tinplate with a thickness of 0.3 mm. he is Going of three parts: the shell and the two covers. In the top of the solder are fixed two copper tube — filling and drainage. The same tube is the choke fuel supply to the engine. The standpipe tube should be sufficiently flexible and does not harden from exposure to fuel. In principle, a good tank can be made of a suitable plastic pharmacy bottle. Only need to check whether it does not dissolve components of the fuel compression or glow engine.

Motor racing aerolister — with pusher propeller, so the image and likeness of standard propeller made of birch or beech will have to make it a mirrored copy. By the way, in many cases, athletes-racers prefer to use on such boats powerplant a tractor propeller, saving yourself from the hassle of making propeller — small but high-precision parts.

The steering device aerolizer consists of a bracket full of duralumin strip with a thickness of 2 mm, plastic ballerinas dural steering box and pen. The latter is spring-loaded, that ensures smooth deviation when entering shallow water or while negotiating the waterlogged items. With the steering machine balerna box connects to the nylon lever and wire rod.

It should be noted that when using more powerful engines (for example, KMD-2,5) has the meaning of all the linear dimensions of the model to increase by approximately 20 percent — with the stability and handling of the model will be slightly better.

To run such models should be in small enclosed bodies of water — only need using three buoys to mark the race track in the form of an isosceles triangle with sides 30, 30 and 20 meters.

I. TEREKHOV