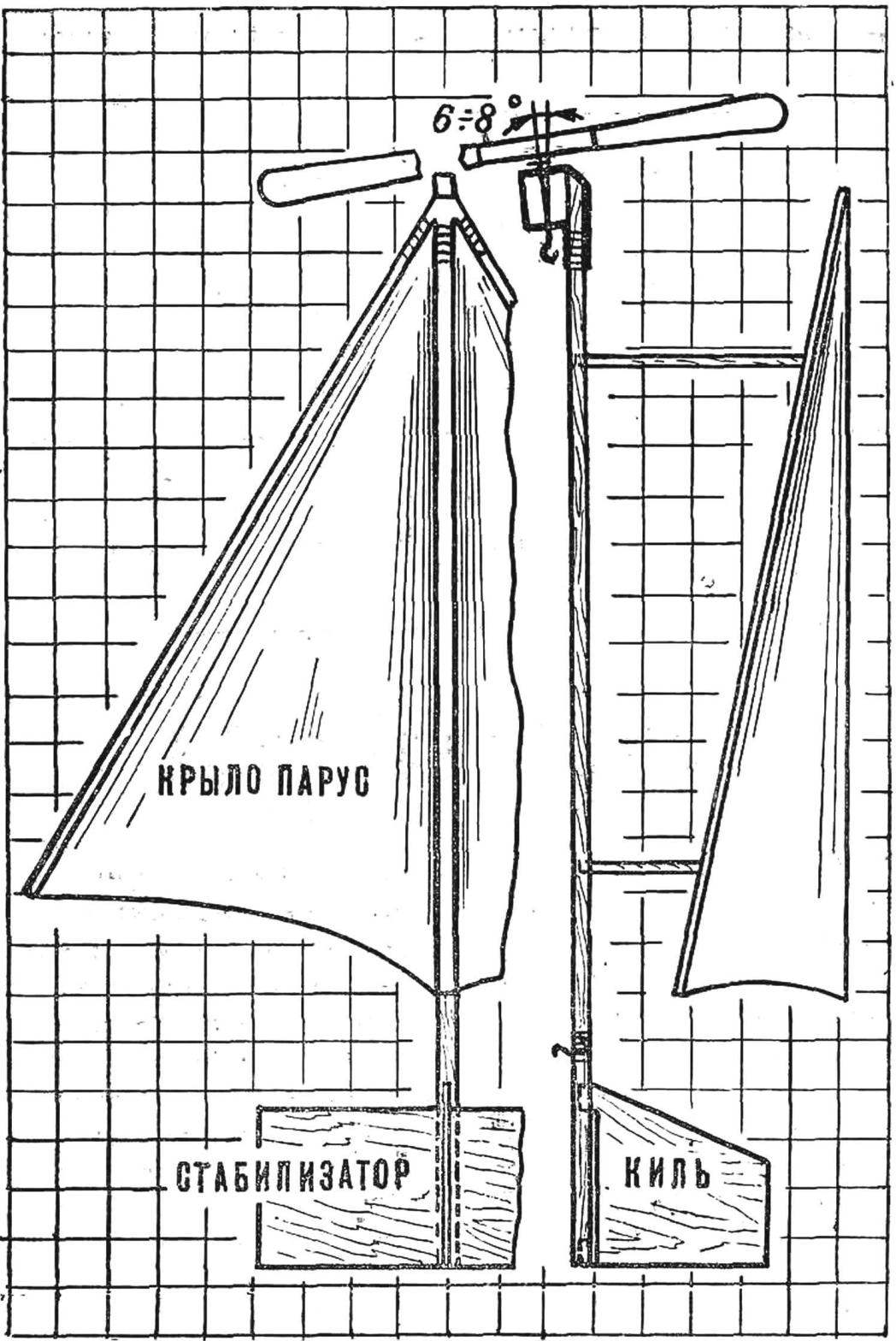

This model can be built in 4-6 hours. It flies well indoors and outdoors. It is designed and built model airplanes Khabarovsk regional station of young technicians. The fuselage is manufactured of pine or Linden slats cross-section 6X5 mm. To the front of the rack using thread and glue to attach the bearing screw is made of tin or aluminum. At the distance indicated in the figure, fix the hook for the rubber motor, wire Ø1 mm. Stabilizer and fin can be made of plywood 1 mm thick veneer or just cardboard. Fix them on glue, make sure there are no distortions. Of Reiki is a cross section of 4X4 mm to prepare two racks of the wing, make the slots in the fuselage and install, as shown in the figure.

This model can be built in 4-6 hours. It flies well indoors and outdoors. It is designed and built model airplanes Khabarovsk regional station of young technicians. The fuselage is manufactured of pine or Linden slats cross-section 6X5 mm. To the front of the rack using thread and glue to attach the bearing screw is made of tin or aluminum. At the distance indicated in the figure, fix the hook for the rubber motor, wire Ø1 mm. Stabilizer and fin can be made of plywood 1 mm thick veneer or just cardboard. Fix them on glue, make sure there are no distortions. Of Reiki is a cross section of 4X4 mm to prepare two racks of the wing, make the slots in the fuselage and install, as shown in the figure.

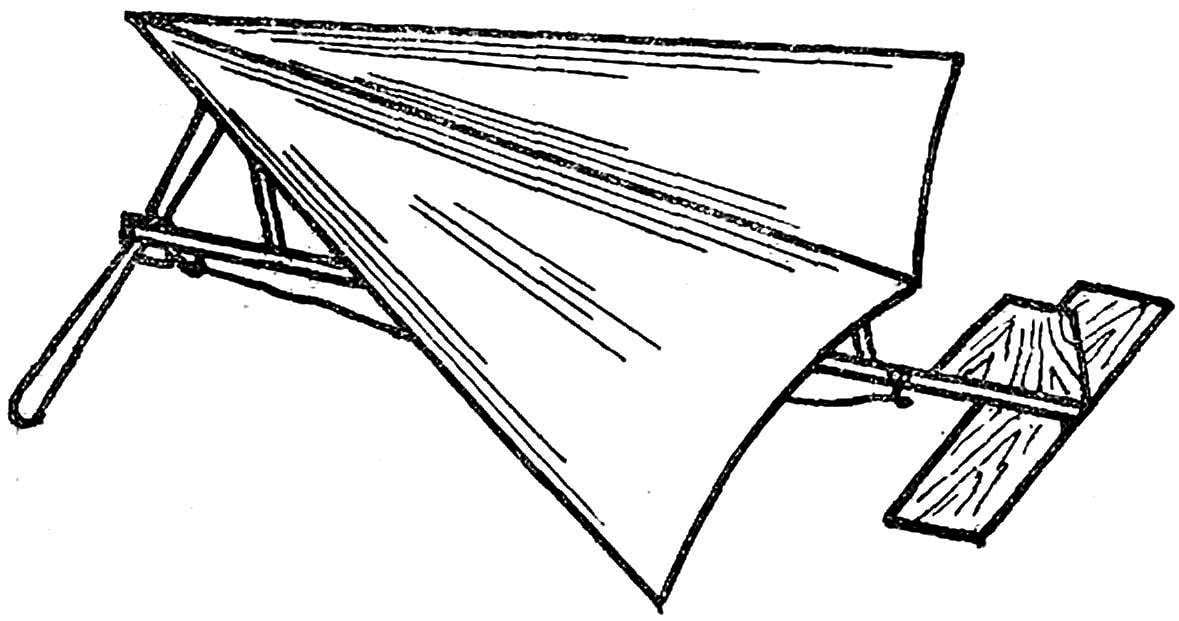

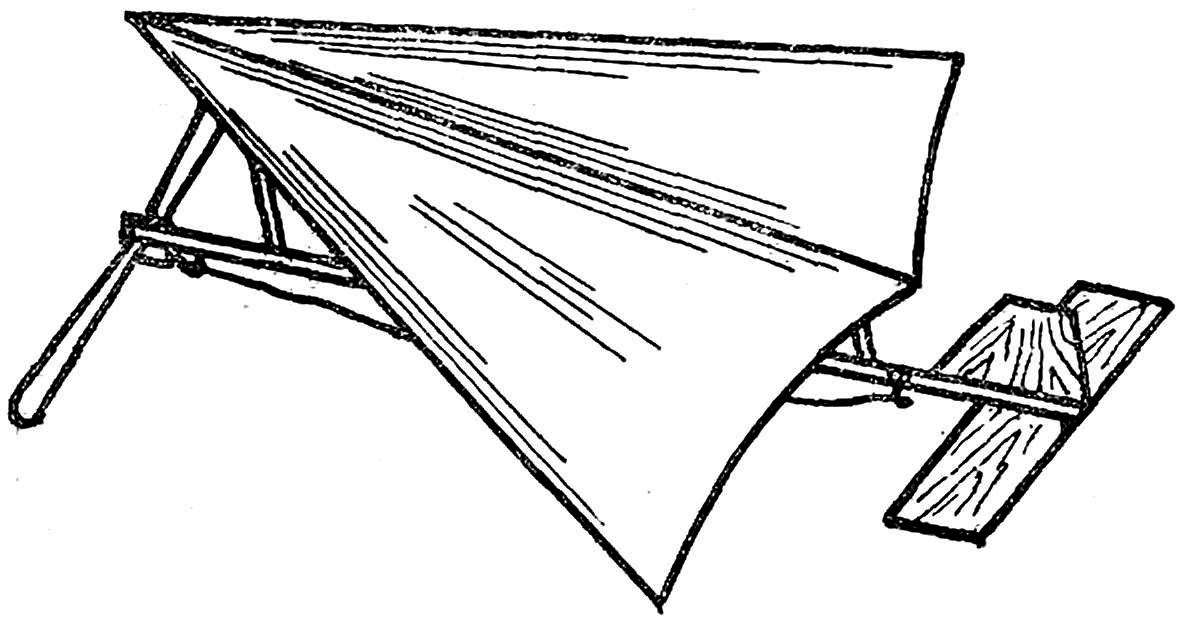

The most time-consuming work — fabrication and mounting of the wing-sail. Three longitudinal slats made of a cross section of 3X3 mm, for mounting them in front of the cut out of tin or thin aluminum angle. On a flat table, lay the spars and using a square, glue and thread to fasten them to the desired angle. To racks fender mounts metal corners. It should be placed horizontally relative to the fuselage and stabilizer.

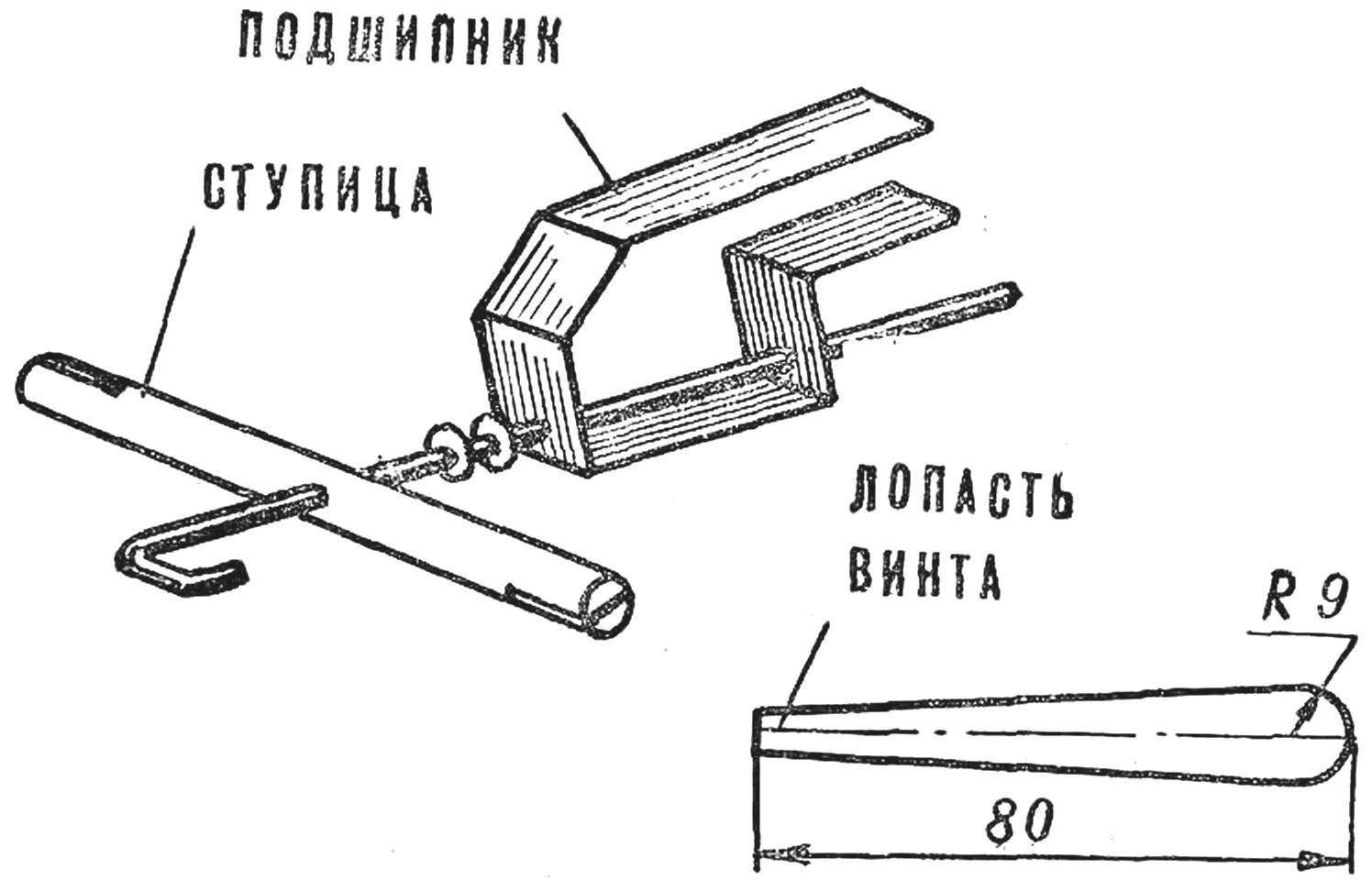

The blades saw out of plywood with a thickness of 1 mm or thick veneer. From round sticks Ø 6 mm make the propeller hub. To install the blades saw through the grooves at an angle of 90°, paste the glue on the blade and drill out the center hub hole Ø 1 mm. Prepared the balance screw on the wire and sand. The axis of the screw make wire Ø 1 mm, one end bend the letter G and type in the hub.

The axis of the propeller should be tilted 6-8° relative to the fuselage, otherwise the model is in flight it will hang. The screw is rotated without jamming between the bearing and the propeller hub place two washers or bead.

The wing-sail glue tissue or condenser paper. Triangular stitched pattern make for 3-4 cm wider than the wing. First tight glue to the main spar, after a to the side edges so that the paper slack.

The rubber motor consists of 10-12 strands of round rubber and its length in a free state should exceed the distance between the hooks on 2-3 cm For the strength of the ends of the rubber motor wind thread and make loop. Lubricate the rubber motor with a few drops of castor oil.

The model is ready! Now it is necessary to test in flight. Pre-stretching the rubber motor 2-3 times, spin it at 200-250 rpm. Giving to spin the screw, gently release the model.

If the plane goes up sharply, fold the rear edge of the stabilizer down; if the model is going to swoop down, then up. By bending the rear edge of the keel until you are satisfied with the flight model circles. Well adjusted and the model can stay in the air 30-40.

V. PETROV, head of the aircraft modeling lab