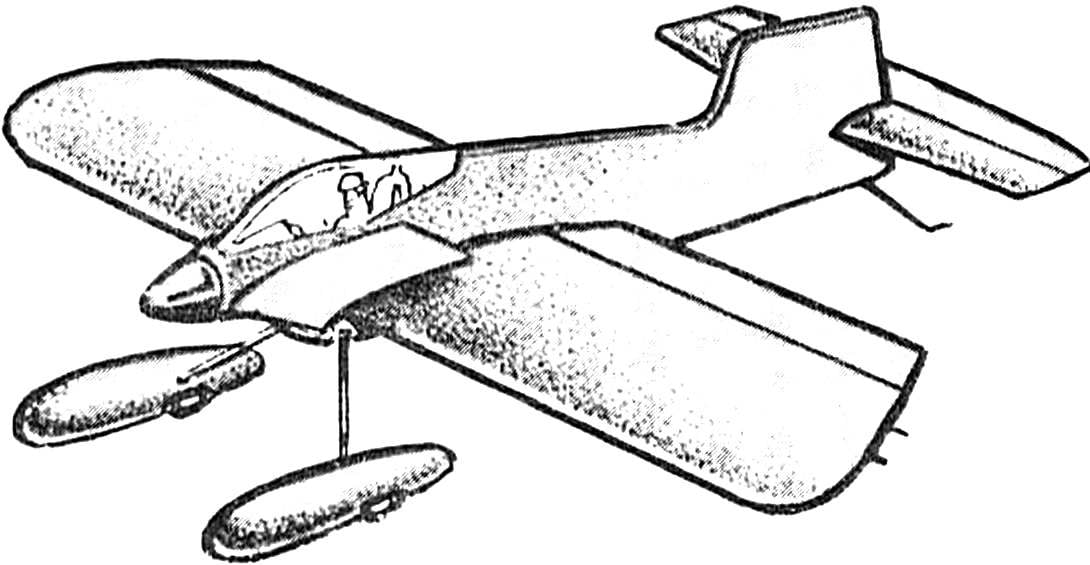

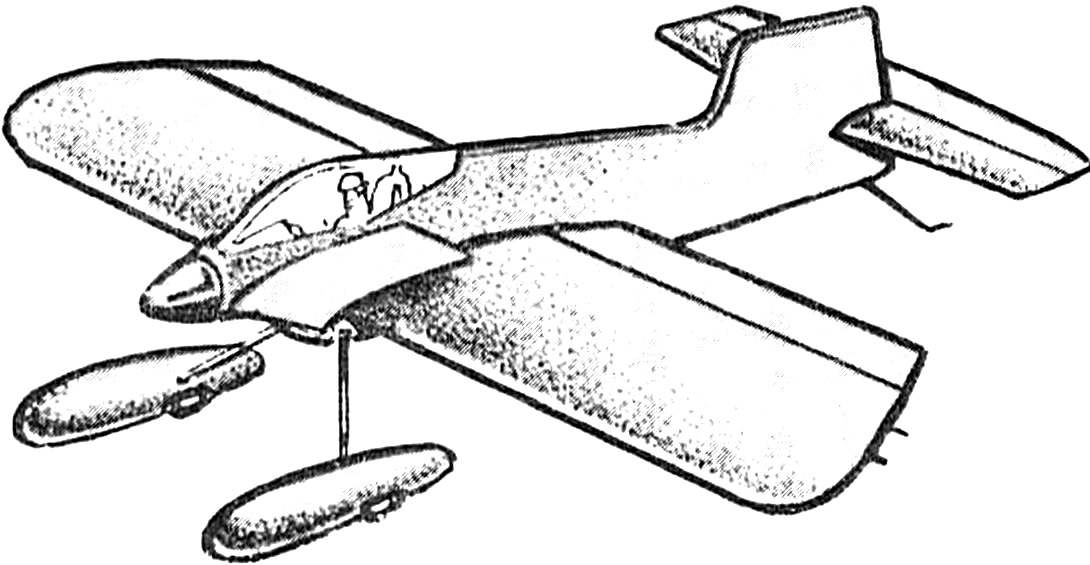

Fig. 1. Control line aerobatic model under the engine working volume of 2.5—3.5 cm3 .

The power scheme is designed for conditions sensitive of deflections when making sharp evolutions. Many years of experience working with models assures the unambiguous and very large. flexible wings. Such flight behaves much “softer”, and at the corners of the “squares” without inhibition is able to fit in a radius of not more than 1 m. in addition, the new wing has another feature: the frame is designed well under the Mylar. In the absence of exposed elements of the set of the film falls flat sheet, effectively drawing only noses of olunurlar. When using metalized or dyed after construction of the model of the Dacron without any putty-shkurovich work turns out amazing quality product. Incidentally, this technique has completely justified itself, and on the tail and on the fuselage — where the entire frame is recessed under the level plating, and the film rests only on a kerb edge. On the wing, it seems, freely “playing” under the influence of aerodynamic loads the sheet tightly stretched film provides an additional effect of increasing the maneuverability of the aircraft at sharp shapes. With elastic at the bend in the wing (twist it with a good tension of the film is very hard!) it is necessary in the suspension system of flaps to enter in the middle of the sliding hinges.

Fig. 2. The wing of the model:

1 — piping tip (Linden 2X4 mm), 2 — the ending (foam PVC thickness 4 mm), 3 — wedge-shaped strut, 4 — wheel rib (basswood or plywood with a thickness of 2…3 mm), 5 — sock-Polonnaruwa (plywood thickness of 2…3 mm), 6 — spacer-rib (pine 4X6 mm), 7 — forehead-spar pine (tight grained), 8 — strengthening spar (pine, 12 mm thick), 9 — piping section fuel tank 10 — the covering of the wing (plywood with a thickness of 1 mm), 11 — load 30 g, 12 — boss for mounting a rocking 13 — regular mesh, 14 — medium loop having the opportunity to move from the wing, 15 — boss loop, 16 — plate trailing edge pine (4X15 mm), 17 — rear flange (pine 4X10 mm) 18 — edge of the flap (pine 5X9 mm), 19, 21 — piping (lime 2 mm thick), 20 — filling flap (foam PS-4-40)22 — trim (heavy paper on the PVA glue), 23 — root boss (Linden), 24 — bracket (OVS wire Ø 2.5 mm).

Fig. 3. Horizontal tail:

1 — edge pine (4X9 mm), 2 — the covering of the wing (presspan 0.3 mm thick), 3 — lining (foam PVC), 4 — spacer plate (foam PVC thickness 1,5…2 mm), 5 — strut (pine 2X2 mm), 6 — the leading edge pine (3X4 mm), 7 — ending (Linden thickness of 2 mm), 8 insert (Linden 9 mm thick), 9 — rear flange (pine 2X4 mm).

Fig. 4. All-moving tail:

1 flange and beam flange (white 3,5X3,5 mm; drawn on the drawing areas between the shelves to glue walls made of pine 2,5X3,5 mm), 2 — wedge Polonnaruwa (Linden 2.5 mm thick), 3 — Board suspension (plywood 4 mm thick), 4 — ending (pine 3,5X5 mm), 5 — spacers (pine 2X3,5 mm), 6 — tail wedge Polonnaruwa (lip thickness of 2.5 mm) 7 — insert (lime 5X10 mm).

Fig. 5. The fuselage of the model:

1 — motor mount (black 15X15 mm), 2 filler (foam 15 mm) 3 — tank, 4 — lug chassis, 5 — edging (pine 2X15 mm), 6 — sheathing the bow (plywood 1.5 mm on both sides), 7 — stringers (pine 6X18 mm, tail width reduced to 12 mm) 8 — rack (pine 6X10 mm), 9 — casing, 10 — circuit layout that supports an arc lamp, 11 — arc (wire Ø 4 mm).

Fig. 6. Control scheme: basic dimensions.

In conclusion, you need to explain why the drawings are shown two versions of the tail. The fact that after the recent breakage in transport, we finally dared to believe the publications in the journal and try to reproduce the all-moving tail instead of the classic, although supporters spent years making. The first takes flight with the new tail gave amazing results. While we still did not have a clear belief that this technique is suitable for beginners, but all the characteristics of flying says it all: it’s the perfect combination of maneuverability and stability. In experienced hands, the machine is the whole set of figures at any point while maintaining a solid stretch and not showing “temper”, even in the wind. Perhaps all subsequent models will build exclusively with telephonically. And the “bluntness” of the educational microplane easily solved by alignment.

Once again I want to note that despite its simplicity, such a flight requires accuracy and care in construction. The whole Assembly is only tested in the case of epoxy resins, the cording also requires prior verification Mylar film and a certain experience with this material, knowledge of technology of gluing superplane.

V. HOLGUIN, A. SOLOVIEV, the athletes of the 1st category

Recommend to read SCREEN-OFFICE If in apartment there is a separate children's room, organize the workplace for a student is not as easy and even more so, if a family has two students. But here, the design savvy home... “ALBATROSS” OF THE 1930S The weakness of the Navy of the USSR in the prewar years, tried to compensate by creating flying cruisers - multi-engined and heavily armed seaplane, able to deal with both surface and...  Meditating and finding equipment for the new sports season, we decided to stop on tested, proven for many years solutions. Sacrilega scheme is not too large wingspan; horizontal tail with stabilizatory part and Elevator… However, the latest publication in the “M-K” made us much more attentive to the consideration of the moments of inertia, and therefore the maximum relief of the tail section, respectively, projected for a very short bow, load-bearing engine. With the usual for pilotaggio measurements was “obladis” — because in the design model, greatly influenced by the shape and length of the nose of the fuselage. However, this problem we managed to solve due to the unusually long chassis fairings. With them the model is not only advantageous to look at the ground, but in flight is not inferior in the perception of long-nosed cars. Benefit appearance and is the simplest closure of the plant verhneraspolozhennyh shields (in the bottom of the engine is completely open), and a large spinner.

Meditating and finding equipment for the new sports season, we decided to stop on tested, proven for many years solutions. Sacrilega scheme is not too large wingspan; horizontal tail with stabilizatory part and Elevator… However, the latest publication in the “M-K” made us much more attentive to the consideration of the moments of inertia, and therefore the maximum relief of the tail section, respectively, projected for a very short bow, load-bearing engine. With the usual for pilotaggio measurements was “obladis” — because in the design model, greatly influenced by the shape and length of the nose of the fuselage. However, this problem we managed to solve due to the unusually long chassis fairings. With them the model is not only advantageous to look at the ground, but in flight is not inferior in the perception of long-nosed cars. Benefit appearance and is the simplest closure of the plant verhneraspolozhennyh shields (in the bottom of the engine is completely open), and a large spinner.