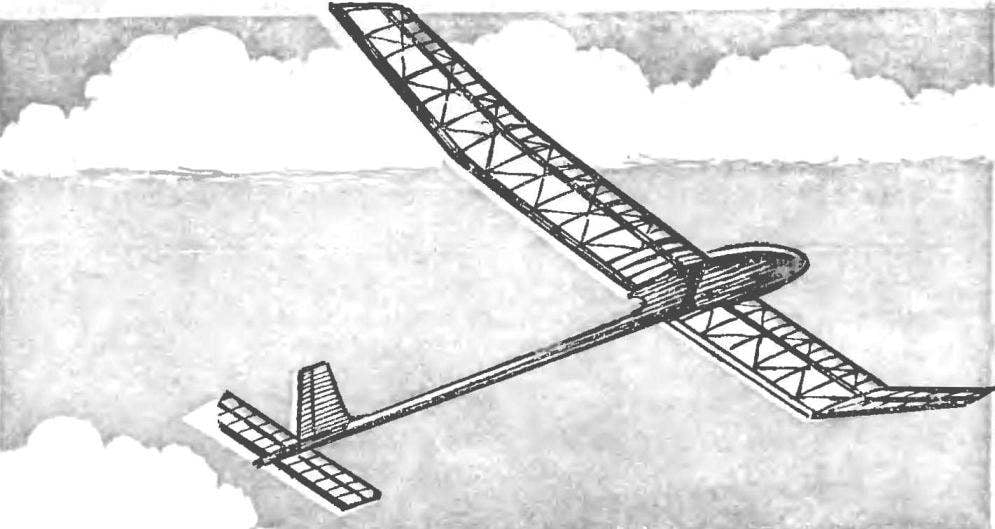

At competitions of the Moscow schoolchildren model pupil of the 55th school Igor Svistunov in adverse weather conditions (wind of 6-10 m / s) scored 501 points. Only breaking model at the start of one of the tours did not allow Igor to achieve absolute victory outcome in all five rounds.

At competitions of the Moscow schoolchildren model pupil of the 55th school Igor Svistunov in adverse weather conditions (wind of 6-10 m / s) scored 501 points. Only breaking model at the start of one of the tours did not allow Igor to achieve absolute victory outcome in all five rounds.

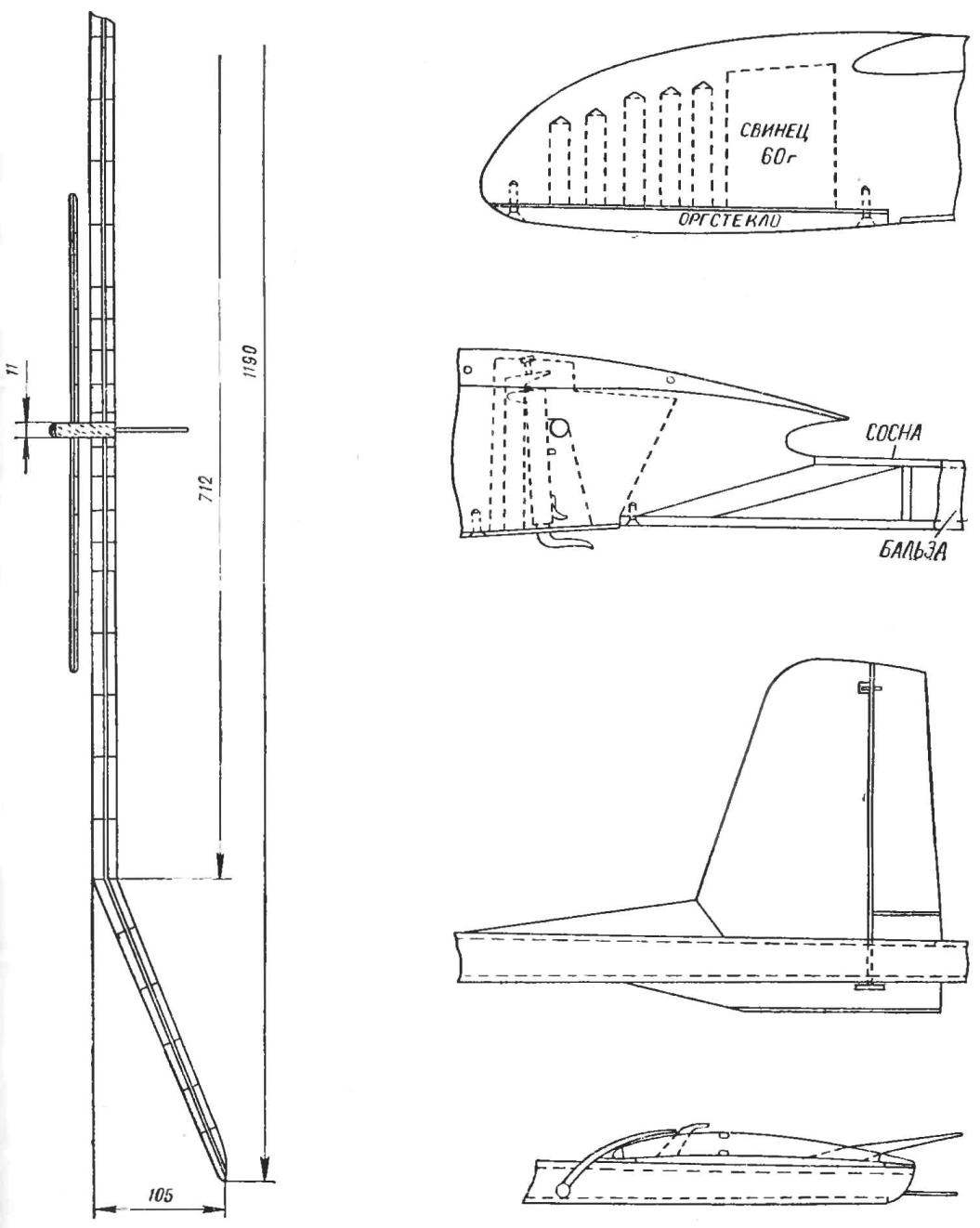

This model has been specially designed length “batch” manufacturing in the circle of the Pioneer Gagarin district; it would be embodied as a long experience of participation in the competition chempionatnym model gliders. First of all, the task was to create a model that would be sufficiently reliable in all weather conditions and is stable in flight. For this it was necessary to design a wing with a geodetic structure (with cross ribs), which is quite justified itself in the future.

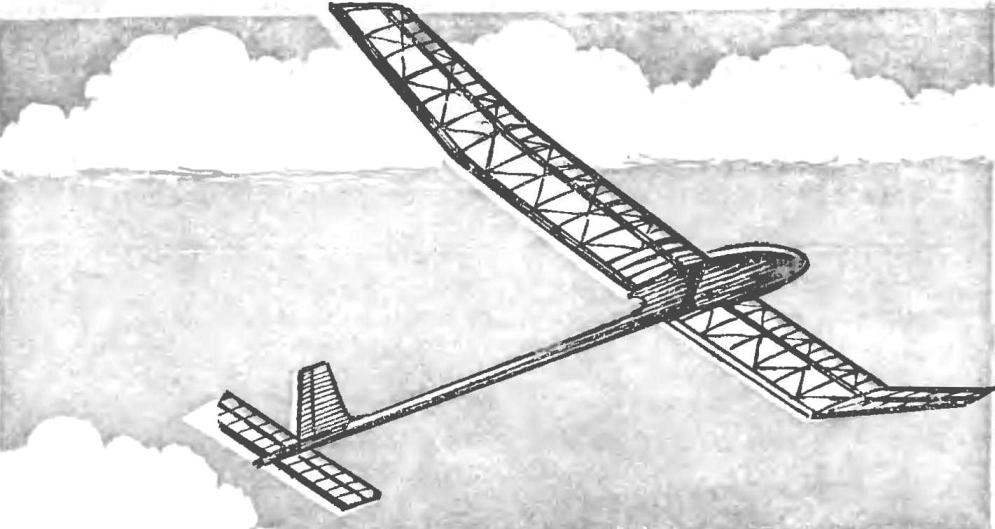

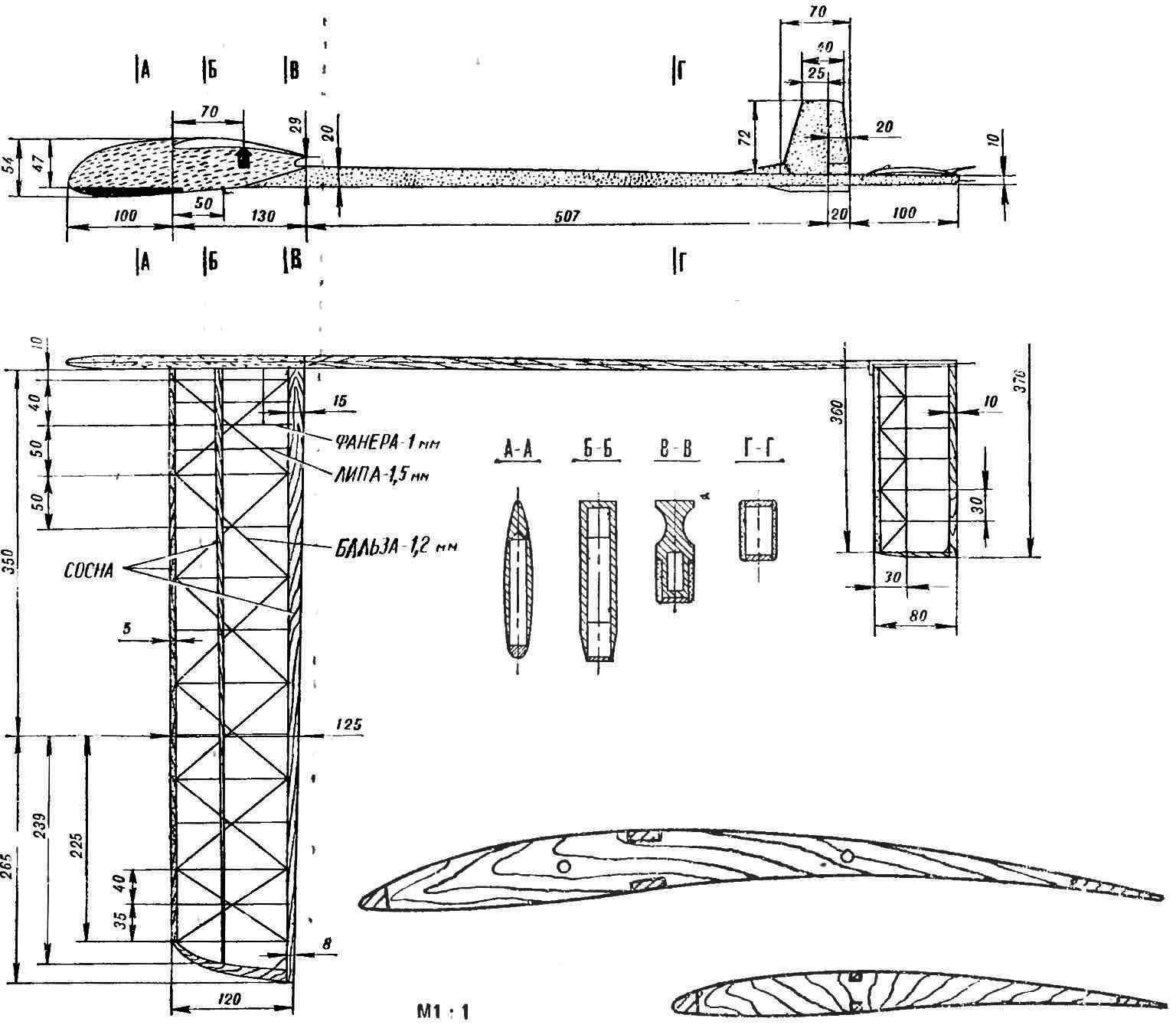

The building model glider wing with the start of production. This mixed construction, consists of 30 standard dvuhpolochnogo ribs and one spar. Moreover this number of six root rib made of 1 mm thick plywood. Two root rib component (the glue) of 2 mm thickness linden plywood and 1 mm thick. The remaining lime ribs, the thickness of 1.5 mm. Console connected through the fuselage by two pins from Allied wire Ø 2 mm.

The wing is assembled as follows.

First, fix the front edge on the stocks (pine 5X5 mm to “ear”, then balsa) and back (solid balsa 15X2 mm). Between them all glued ribs. After that, put the cruciform rib – balsa plate 1.2 mm thick. When the entire structure is dry razor cut grooves in place under the top shelf spar having a section of 6×2 mm on one side and 2×1 MM – other. Sandpaper the handle is flush with the wing profile is glued balsa plate and shelf. In the same way they put the bottom shelf of the second side member (section 6X1,5 mm with a 2X1 mm and the other side) and modify the wing profile. Nozzles semi-ribs is treated on site. The finished console cut thin slits in the center-Coy and zakontsovku- “ear”, the last cut at the desired angle and glued to the center-to-end enamel. After drying and customize glued connecting plate – corners, and between the leading and trailing edges and glued balsa spar rib is 5 mm thick.

Wing paste mica paper and coated 5-7 times with liquid emalitom. The weight of the finished wing – 56 g.

Stabilizer balsa. The leading edge section of 5×4 mm and rear – 10×2 mm made of solid balsa. Rib – 0.8 mm. The stringers and longerons pine section 2X1 mm & 1X1 mm. The root rib is glued together from two lime plates 0.8 mm thick balsa 3 mm thick. It secured a bamboo rod and hook. Stabilizer paste thin mica paper. Weight of the stabilizer 6

The fuselage of the model consists of two elements: the nose and tail ravine. The first cut of beech board section 250 x 60×11 mm. Bottom drilled holes for loading and locking hook. Cavities for downloading closed strip of Plexiglas with two M2 screws.

After finishing a nose portion is etched with an aqueous solution of the aniline dye and covered with several layers of emalita or AB-4 varnish.

The tail boom has two pine stringers section 8X2,5 mm at the root and at the end of 6X1 mm balsa and two side plates 1.5 mm thick. Stringers bonded epoxy resin EH is 5 to bow. Then the distance between them is 80 mm apart from balsa struts set 2 mm thick. After the treatment beam balsa plates sewn on resin ED-5 (from the inside of the plate, too, need to cover with a thin layer of resin). Finally, the entire fuselage covered with 3-4 layers emalita. All the details can be replaced with lime balsa, reducing their thickness by half.

Kiel – balsa-section 2 mm.

Kabanchik for securing stabilizer – hornbeam plywood and 1 mm thick.

After final assembly of the model loads in addition to get the estimated weight, and adjusted the alignment. Center of gravity of the model is 70 mm from the front edge (53%).

On the wing fix energizer thread Ø 0.3 mm at a distance of 7 mm from the front edge.

A. Averyanov, the master of sports