To the ends of the leads soldered carabiners made of steel wire with a diameter of 1 mm (on them before the flight, put loop cord control). Before soldering on carbines wearing the clamps of the copper tube of suitable diameter. For example, crop tubes the fuel tank. This is important for reliable closing of the carabiner and fly. The length of the cord from the longitudinal axis of the model to handle pin management 17 690 mm. the radius of the flight will fly a measuring base of 1 km for the first nine laps.

HANDLE MANAGEMENT of dural plate thickness

3 mm. on both sides of the aluminum rivets with a diameter of 4-5 mm wooden lining comfortable for the hands shape. The difference between this handles from knobs kordovye models of other classes is that in the center of the arc is fixed a metal pin with a diameter of 10 mm and a length of 120 mm, which during test flight rests in the fork rack, installed in the center of the track.

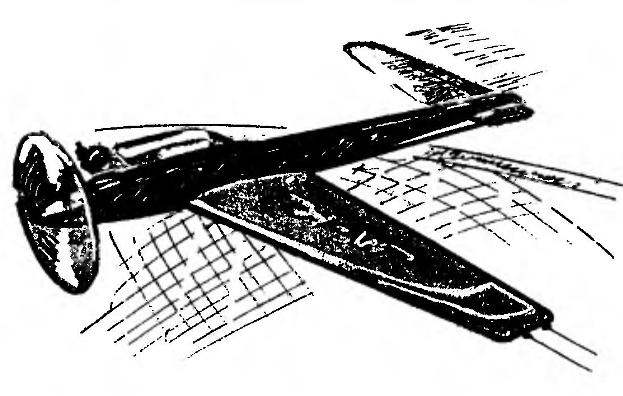

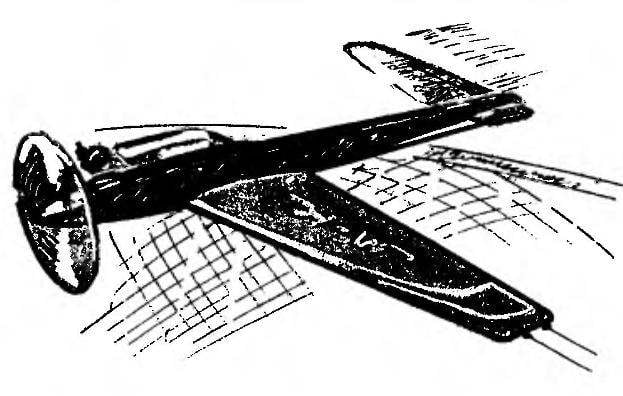

ENGINE KMD-2.5 or the other with the same volume of the cylinder. Before the competition it must be well run and carefully adjusted.

The PROPELLER – standard, plastic dimensions 200×200 mm 180×160 mm. the First is used for training flights to save the life of the engine, the second in the competition, when it works at maximum capacity. You can experiment with standard screw sizes 200×200 mm, cutting blades 10-15 mm; however, it should be balanced.

FUEL TANK is made of tinplate, with thickness of 0.3 mm (you can use tin cans of condensed milk). All seams and places the input tubes are securely sealed and checked for leaks. Special attention should be paid to the fact that the end of the tube power of the motor is soldered to the top of the tank. Filling

the tube is placed closer to the front wall, and its lower end rests on the bottom. This is useful when draining fuel after the flight, when the model leans forward. Filling to perform better in the vertical position of the wing. It provides a complete fill of the tank. In another method may not be enough fuel on the passage of the measuring base.

TAKE-OFF DEVICE. Chassis the model is not, therefore, to rise used three-wheeled cart. After separation of the model from the surface it remains on track. The cart made of steel wire with a diameter of 2-3 mm. the design can be any, because the mass doesn’t matter. The diameter of the wheels can also be anything, however, track width of front wheels (40 mm diameter) should be not less than 250 mm and the base distance between the axles of the front and rear wheels (diameter 25 mm) is equal to the track. Frame with cradles for the fuselage and struts for the wing, on which is placed a model before the start, must be strictly horizontal.

ASSEMBLY. For bonding the airfoils used PVA glue, but for the final build epoxy. Before painting all surfaces of the model putty and primed one to two times. For painting, you can use a regular car nitroenamels in cans. The final finish is applied on one side of the top of the year it was built and the initials of the author.

The Assembly begins after the individual elements of the control system installed at the places of their fastening: rocking chair with a leash cord (short thrust) on the wing and horn on the Elevator. Then the wing and stabilizer epoxy glue is fixed in the corresponding slots of the fuselage. After the glue dries completed the installation of the control system, securing in place the end of a rod of the Elevator. On both ends of the wear washer of thin sheet metal (two pieces) and solder them to provide a free (no backlash) movement in holes rocking and wild boar. Arching thrust of an Elevator, adjust the entire control system. Bending angles is selected so that the neutral position of the rocking of the Elevator was also in the same position.

Then mounted the fuel tank. Moreover, its bottom should not interfere with the free movement of traction of the Elevator. The tank is attached to the fuselage with two M3 screws on the right side above the rocking chair. The front screw is fixed, and with the rear adjustable gap between the tank wall and the airframe. Adjustment in the range of 1 -5 mm is ensured by elastic silicone tube with a diameter of 5 mm, length 8— 10 mm mounted on an M3 screw. It allows for the compression to find the optimal position of the tank, which is provided by the best fuel supply. It is important for the stable operation of the engine at maximum speed. At last the model install the engine with the air screw and connect the fuel line to the tank.

ADJUSTMENT of the deflection angle of the Elevator depends on the skill of the pilot, the higher installed thrust on the hog, the smaller the angle of deflection. Experienced modelers recommend to set higher starting below.

BALANCING. The center of gravity of the model should be located on the axis of a rocking chair. In the case of deviations in the fuselage and drill a small recess in which is placed lead weight. Then the hole is glued up. The mass of the collected models without engine and fuel 200 g

In piloting the model is available beginning “skorostyam”. When well adjusted the engine and properly adjusted the air screw it is capable of speeds up to 140 km/h.

G. PICHUGIN, teacher of the highest category, head of aviamodelirovaniye