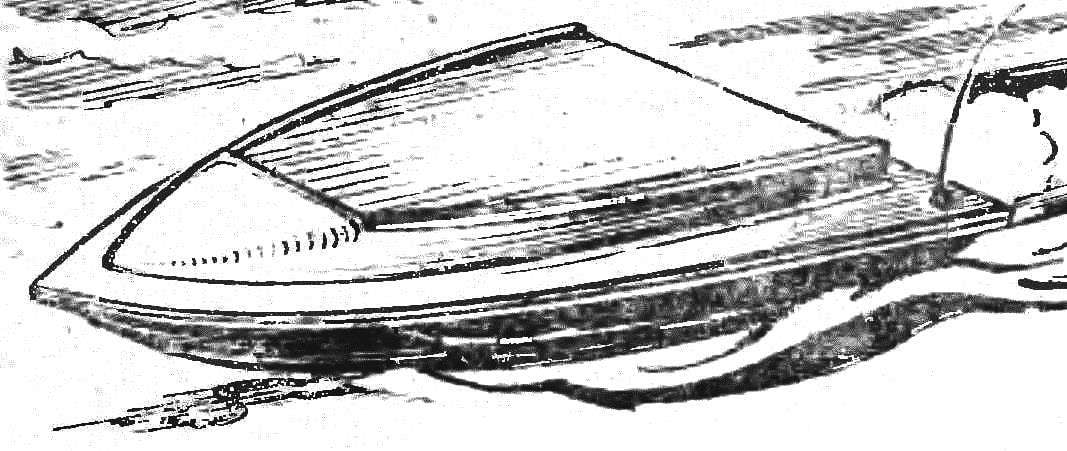

Just about such models, and we will tell today. All the materials for its manufacture are available, the construction and operation of simple, uncomplicated and commissioning. The basis for the development of the contours of the RC taken publication in the Yugoslav magazine “ABC engineering”; the resulting design is fit for domestic power system and batteries.

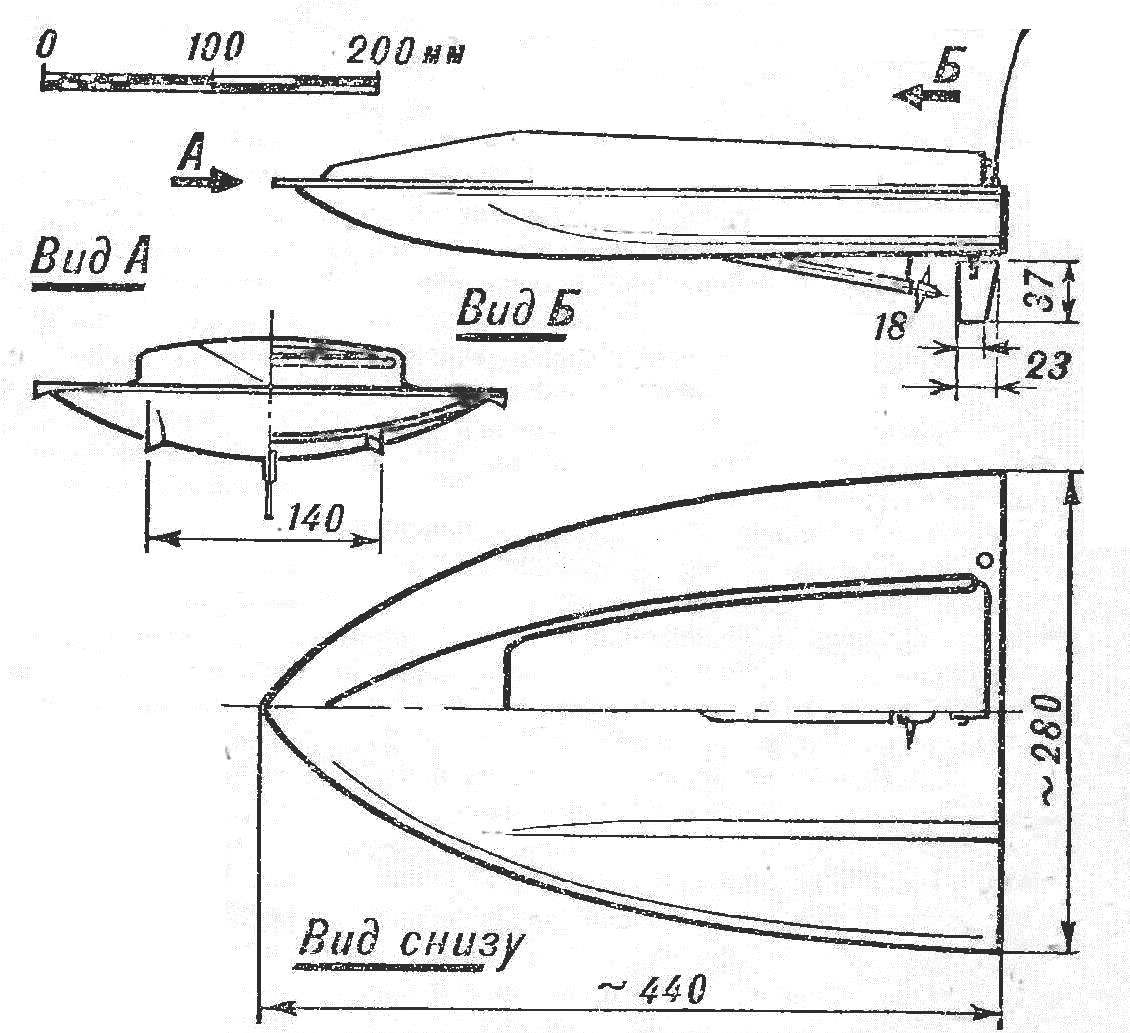

RC sudomodel motor :

1 — deck, 2 — body, 3 — side wall, 4 — cover,5 — forward frame,6 — wall of the compartment 7 is under engine bulkhead, 8 — the stern wall of the well, 9 — guide,10 — medium frame,II — transom frame, 12 — cover, 13 — transom, 14 — gelmanova tube, 15 — the rudder stock 16 rudder 17 — everything 18 — complete industrial power system 19 — compartment radio, 20 — .area of batteries si-povolo motor, 21 — foam filling in the side compartments of the flooding, 22 — zygomatic rail, 23 — butt rack-stringer, 24 — longitudinal redan.

Work on the model begins with cutting sheets of plywood with a thickness of 1 mm according to the drawings made on graph paper in full size. Note: preset items must be flowed to the direction of the layer (fiber) to the “sleeve” plywood coincide with the arrow on the drawings in the journal.

Then cut all the blanks and from the deck with a jigsaw with fine teeth with a thin blade remove the cover. The deck over grooved gasket with a minimum thickness of 30 mm is set on the flat Board stocks. And “roughly” fixed frames. At the cut edge of the workpiece panel drill hole d 1 mm with a pitch of about 10 mm and pull together the edges of the thin copper wire or strong thread. When fitting the hull elements may pridesa to cut the contours of the formers; in the drawings they are stock height, cut only after complete Assembly of the boat.

After ensuring tight joining of all parts, seams shed svezhenakleennyh epoxy resin. “Tailoring” seam at the bow of the hull must be reinforced from the inside impregnated with resin strap. The edge of the housing can be clamped to the deck clothespins (if the free edge of the deck) or kill the padding of the bench by pressing the sewing pins.

While the case is on the stocks, it is useful to mount a rack, performing the functions of longitudinal planing steps, give them a wedge-shaped cross-section, stick zygomatic Reiki.

After complete curing of the resin case is removed from the pile, the side sections are filled with foam (preferably packaging, makasarili), pasted the elements of the frame compartment and the nose “fairing”. Special attention should be paid to the mounting of the guide rails, forming a narrow groove under the cover.

Harvesting body parts models .

The last step of installation of the engine. Fit with parts of the housing part of the shaft tube must be thoroughly sanded and degreased, so that after curing of epoxy glue all the seams were sealed. Installation of the plant firmly greatly simplifies the Assembly of the model, however, it is more rational to ensure that the anchor shaft can be removed from shaft tube forward. For this “cone” will have to make removable, and the deck and the front bulkhead to seal in the semi-circular cutouts guide polocrosse of plastic or heavy paper. Then the body vyshkurivaetsya and is covered with several thin layers of hardwood varnish, if desired, it can be partially painted with waterproof enamel.

The basic variant of the power supply while accelerated serial microelectromotors ten elements 343, connected by two parallel problemami of five batteries each. As a result of connections formed by the source capacity of about 1 A • 4 to a voltage of 7.5 V. Before you start, if you’re going to be in the class F1—E or similar — FЗ — E, be sure to check the ground fully prepared for the start of the model! It is according to the requirements of the rules of the competition should not exceed 1 kg. If you do not overdo it with the resin in the Assembly of the hull, weight микрокfтера meet the standard. Excess weight “trim”, remove one battery from each Bank of supply. By the way, for performances in the classroom FСР-E such, of reduced voltage power supply is preferable.

Transition to voltage in excess of 9, unwanted — occurring overheating leads to reduced efficiency of the permanent solenoid motor. Engine power can be increased significantly using the recommendations given in the “M-K” No. 8, 1982. If proposed in the article “Unusual electrolet” improvements to support the replacement of the permanent magnets to those used in door latches (their resistance is much higher), and a magnetic core made of annealed iron, it makes sense to deal with the selection of a power source of high voltage.

V. ARTASHES

Recommend to read ROLL ON THE PEDESTAL Every housewife in the kitchen Arsenal are the rolls of napkin paper or foil. But to use them and store them without special tools is not very convenient. Make a simple stand — and you... GUIDE FOR THE GLASS CUTTER If you want to cut the glass not by the usual straight lines and sinuous, shaped (e.g., stained glass) — the plot thickens. However, it will be easier to perform if under the glass to...  Long gone are the days when the construction of the RC was the prerogative of only experienced, cool modelers. Today, even the newbies that come to join the circle, to the question of what they would like to do, we always answer: “high-Speed RC”.

Long gone are the days when the construction of the RC was the prerogative of only experienced, cool modelers. Today, even the newbies that come to join the circle, to the question of what they would like to do, we always answer: “high-Speed RC”.