The wheel is usually made of foam (Fig. 14). A hole in it for the axis is drilled after gluing on both sides a reinforcing plywood plates 3 mm thick To reduce friction in a wheel is inserted into a copper or tin (bent from strips of sheet metal) tube. Without reinforcement of the side plates, the wheel model, despite the presence of the sleeve melts and begins to touch the rack.

Side of the wheel is sealed with a circle of construction paper that hides defects in the installation of lining, mimicking the drive wheels of foam rubber conform more to the prototype, but require special care — they are “afraid” of fuel from the engine.

On the real aircraft stands installed flaps covering the hatches of the landing gear. Characteristic of the plane shape must be repeated on model.

The control system (Fig. 15) consists of two flexible rods made of steel wire Ø 0,6—0,7 mm, tripledeal dural (S = 1.5 mm) of the swing, the axis of which revolves in the ears attached to the fuselage bracket and wooden end with two wire Ø 1.5 mm tip, aluminum rocking chair, riveted to the steering wheel height, plywood or wire guides on the left wing for the passage of tie rods (POS. 6). These guides are located at 20 to 30 mm behind the center of gravity of the model. In flight the fuselage should not be directed tangentially to the trajectory and nose out of the circle. It is necessary for the tension cords, that is, provide reliable Elevator control. So the model does not roll inside the circle under the weight of the cord or from the occasional gust of wind, the external right-wing heavier load 20-30 g of the rocking Bracket can be installed on either side of the fuselage, but for aesthetic reasons (the desire to maintain a large number of copies per cell on the left side) motor unit with tank, rocking chair, thrust and Elevator are located to starboard, and in the fuselage drill two holes for the passage of the flexible rods.

After installation of all units of the model again determines the location of its center of gravity. It needs to be ahead of the first quarter chord of the wing.

Fig. 10. Versions of the wing tips:

1 — hard shell, 2 — the ending of the wooden plate, 3 — the ending of the foam.

Fig. 11. Installation of the wing relative to the fuselage before gluing.

Fig. 12. Installation horizontal and vertical stabilizer on the fuselage of the model:

1 Kil, 2 — glue, 3 — horizontal tail, 4 — beadings, 5 — fuselage.

Fig. 13. Options for landing gear for aircraft of various types.

Fig. 14. Wheel:

1 — “disc” (drawing paper), 2 — metal tube-bushing, 3 — wheel (foam).

Fig. 15. The elements of the management system model:

1 — rocking chair, 2 — winding (thread) and glue, 3 — desire (pine), a 4 — winding (thread) and glue, 5 — castle (wire solder solder POS-40), 6 — pull.

The slinky model paper: fuselage — micuenta or writing on the front of the wing and near the fuselage drawing, in other places — micuenta or writing. For stickers it is best to use PVA glue. Paper trim models have to cover two times with nitro lacquer an-1 (emalit), which can be replaced with a solution of celluloid in a solvent for nitropaints or acetone. The second coating is 3-4 hours after full drying of the first. To paint the model, preferably by spray or spray a liquid solution of a medium. Before painting, practice painting art on any other subject. After all, the quality of this operation depends on the final appearance of the model.

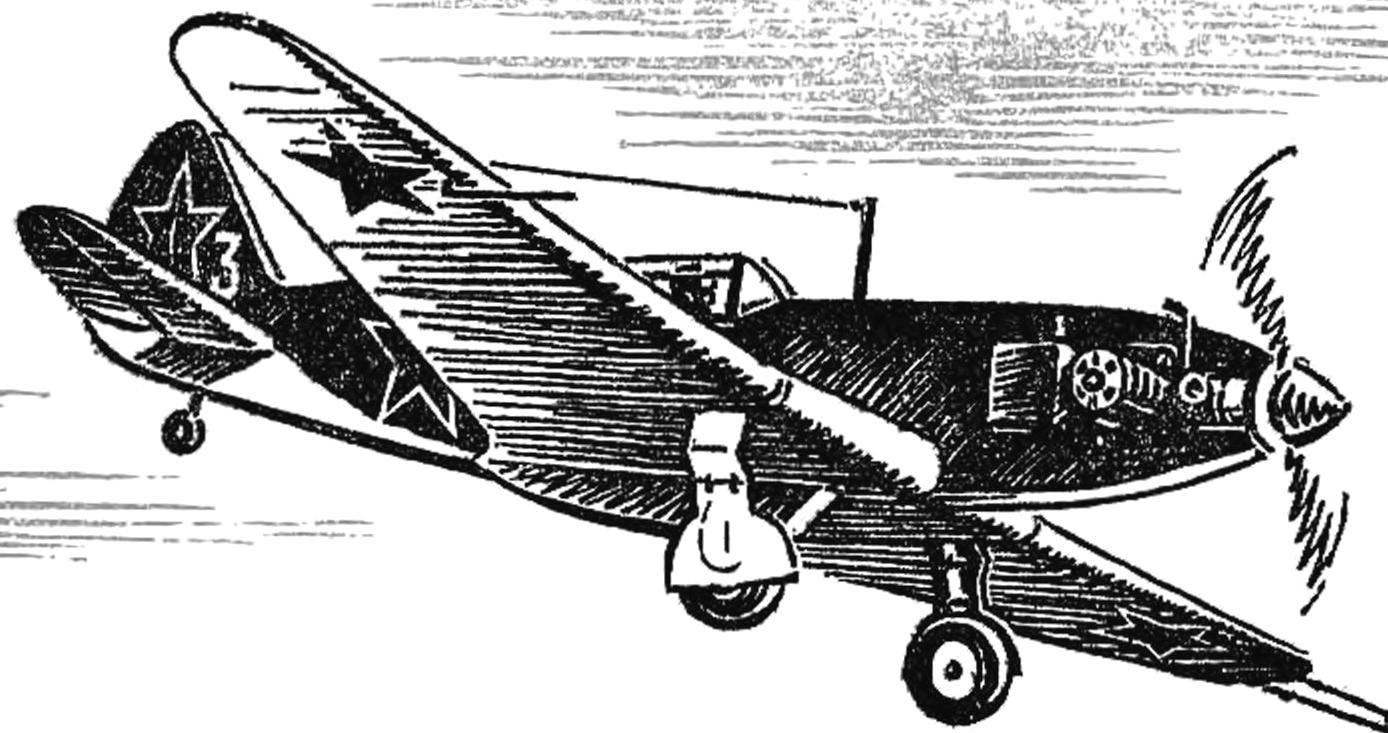

The typical color of military planes blue on the bottom and different shades of green or khaki top. Many of the aircraft had a top-camouflage-camouflage color stains of green and brown.

The red stars on the wings, fuselage and the empennage at the beginning of the great Patriotic war did not have white edging along the contour.

Rims usually green or gray colors, the “tires” black. The color of the tires need to be regularly restored, as the paint is erased on the ground during takeoff and landing.

After painting is done final balancing. The center of gravity of the finished model must be within the first quarter the width of the wing. In most cases you have to load the bow of the additional metal shims under the mounting bolts of the engine, since the rear alignment (heavier tail) model does not obey the helm of the altitude and flying erratically.

S. MALIK

(THE BUILD-POLYOPIA). Building the model-polyopia begin with the manufacture of the fuselage (Fig. 1), the contours of the lateral projection should most accurately reflect the similarity with the copied aircraft. To the fuselage structure demands maximum strength with minimum weight. The greatest difficulty in its manufacture is the reduction in the weight of the tail, which is much longer than the front, So it makes truss.

(THE BUILD-POLYOPIA). Building the model-polyopia begin with the manufacture of the fuselage (Fig. 1), the contours of the lateral projection should most accurately reflect the similarity with the copied aircraft. To the fuselage structure demands maximum strength with minimum weight. The greatest difficulty in its manufacture is the reduction in the weight of the tail, which is much longer than the front, So it makes truss.