We offer proven our ship mug method: to make propellers with electric current from foam. Simple device allows you to quickly produce a series of identical screws, which in appearance is no different from bronze, but do not sink in water.

Material for screws is rigid foam stamps SS-1-200. Workpiece thickness 12-20mm can be any shape: round, square, etc. In the center of each drilled hole Ø 3 mm, for propeller shaft, it also serves as a guide in the manufacture of the screw.

Education of the blades occurs on the device, which we called “Vintorez” (Fig. 1). It consists of a body and three M3 screws is attached to the insulator. At last with the help of clamps and screws set M3 cutting element from nichrome wire Ø 0,8 mm.

For three-bladed propeller undertake three pieces of wire. The distance between them to screw with stepper for 1.5 to approximately 5 mm. For screws with a large step against this distance is reduced and, conversely, for screws with a smaller step ratio increases. You should pay special attention to the axle, which is clamped in the housing screw M4 X 35, were at the center of cutting elements. All three elements are connected in series by means of two jumpers. The voltage applied to them, about 5V.

On the case screws are mounted two of the copier. The angle of the inclined line of each depends on the desired characteristics of the screws and varies with the height h. For the manufacture of the blades must me the axle to put on the foam billet and driver, pick up a workpiece on the knob and sank to the copier so that the handle knob lay on the highest part of the body. After turning on the power, wait 2-3 sec, until heated nichrome, and start gently rotating the knob, pressing his hands to copy. At the end of the cutting should be turned off, to give the billet to cool down, then loosening the fasteners, remove the axle and remove the screw.

Fig. 1. Vintorez:

1 — base, steel-3 — 1 PC., 2 — screw М3Х10 — 21 PCs, 3 — copier, tin 0,3—0,5 — 2 PCs, 4 — blank screw, 5 — knob, steel-H — 1 PC, 6 — axle, steel-45 — 1 PCs., 7 — screw М4Х35 — 1 PC, 8 — puck-3 — 6 PCs, 9 — cutter — 3 PCs., 10 — insulator — 1pc, 11 — clamp — 6 PCs, 12 — jumper — 2.

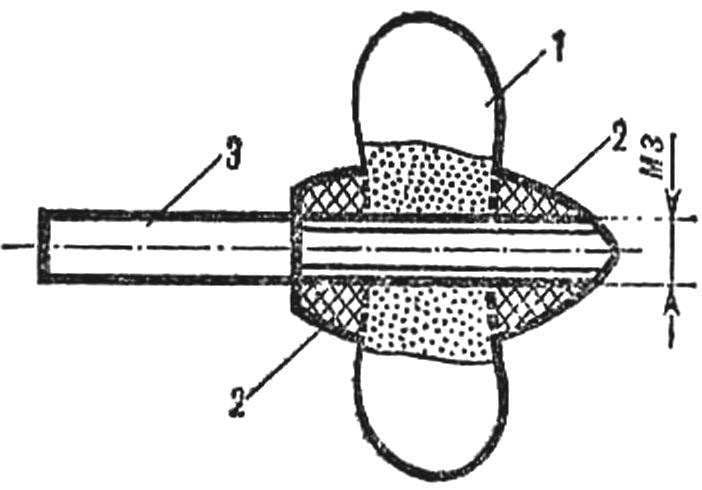

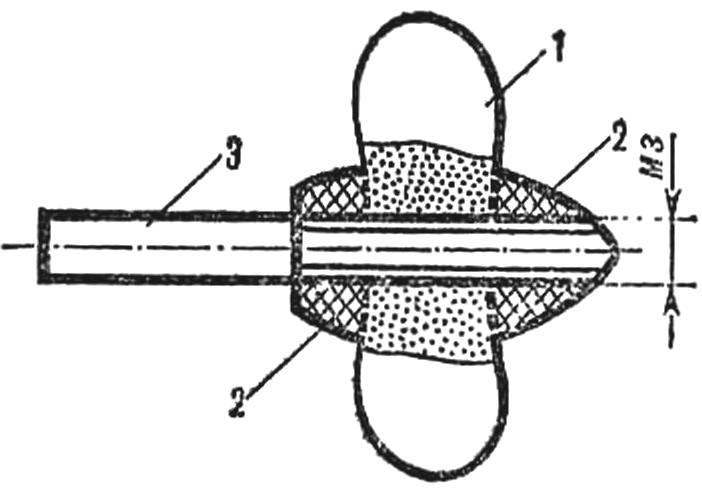

Fig. 2. A device for machining propellers:

1 — base, getinaks, PCB — 1 piece, 2 — front, getinaks, PCB, 1 PC., 3 — strap, brass — 1 PC., 4 — screw МЗХ15 — 6 pieces, 5 — screw МЗХ20 — 2 PCs., 6 — strap, brass — 4 pieces, 7 — cutting element, nichrome Ø0,8 — 1 EA., 8 — axle, steel-45 — 1 PCs., 9 — blank screw, foam — 1 PC., 10 — bushing, brass — 1 PC.; 11 — screw М4Х60 — 1 PC., 12 — nut M3 — 10 pieces 13 — washer — 12 PCs, 14 — bar — 1 PC, 15 — МЗХ10 screw — 2 PCs.

Processing of the contour is performed on the device which is shown in figure 2. It consists of the grounds on which the groove moves to the stand with the cutting element. The latter is attached to the rack bars. From falling out the rack from the bottom and rear hold the two bars. Moving forward is limited by an adjusting screw allows for setting the desired diameter of the propeller. Before operating the rack with the cutting element withdrawn to the rear position. On pressed into the base of the axis is put on the workpiece screw with ready blades. Height relative to the cutting element, the workpiece is fixed by the bushing. After turning on the power source front moves forward until the stop screw.

Now smoothly rotate the workpiece around the axis. Thus, the heated cutting element cuts a workpiece along the contour.

Cover screws with copper consists of two operations: the application of a conductive layer and an electroplating treatment.

On the prepared-to-cover screw is applied a thin layer of epoxy glue. When he starts to “grab”, it should be thoroughly sprinkled with bronze dust (and even better to dip the screw in a jar of powder). The electroplating bath can serve as a wide-mouthed glass jar with two copper plates-anodes (Fig. 4).

Fig. 3. Fairing of the propeller:

1 — blades, 2 — blister, 3 — propeller shaft.

Fig. 4. Galvanic bath:

1 — screw, 2 — anode, 3 — electrolyte, 4 — bath.

The composition of the electrolyte per 1 liter of solution copper sulphate is 170-200 g, sulfuric (battery) acid 60-70 g. First water soluble copper sulphate, and then the vessel carefully poured sulfuric acid.

The power source can be batteries of the flashlight or the rectifier. A voltage of 5-12 V. the current intensity of 0.3—0.5 A. Time coverage 2-3 hours

Propellers must be fastened to the shaft with epoxy glue with the help of the fairings, which act as nuts (Fig. 3).

A. KOLOTOVKIN, g. Klintsy

Recommend to read ECONOMIZER FOR HOUSEHOLD APPLIANCES There is a whole class of electronic devices that operate in standby mode, "waking up" only for a short time to perform their tasks, such as apartment bell, simple security system,... ATTENTION! THE TARGET IN THE AIR "...In the snow two wide pits. In the middle of their wooden houses to install guns the muzzles up. Log cabins are easy to rotate and allow you to hit a flying airplane" — says in "Notes...  We offer proven our ship mug method: to make propellers with electric current from foam. Simple device allows you to quickly produce a series of identical screws, which in appearance is no different from bronze, but do not sink in water.

We offer proven our ship mug method: to make propellers with electric current from foam. Simple device allows you to quickly produce a series of identical screws, which in appearance is no different from bronze, but do not sink in water.