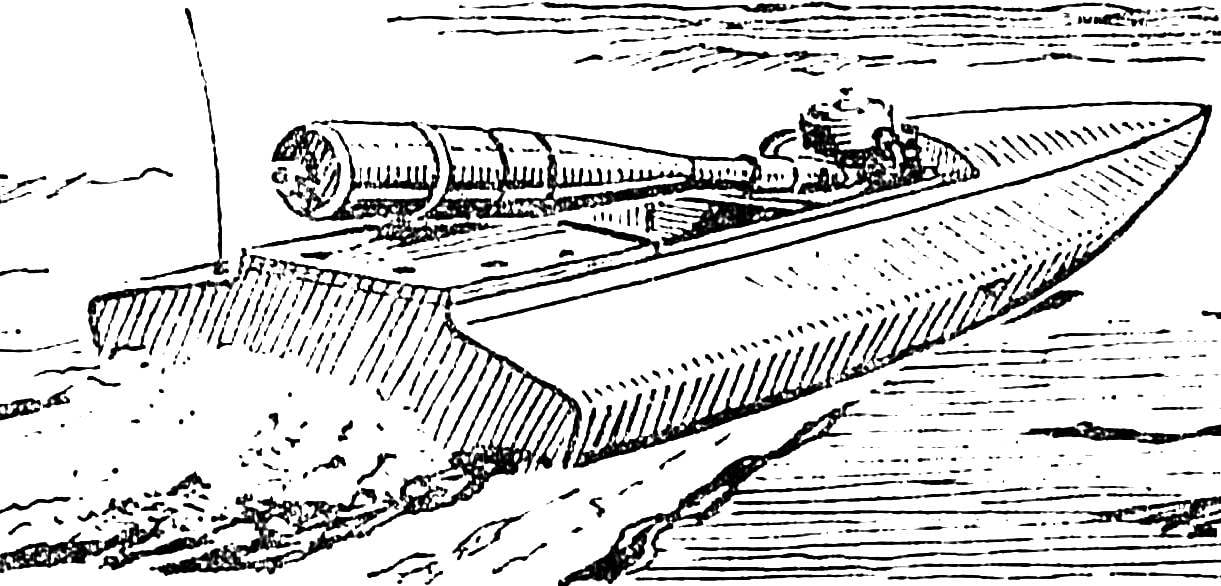

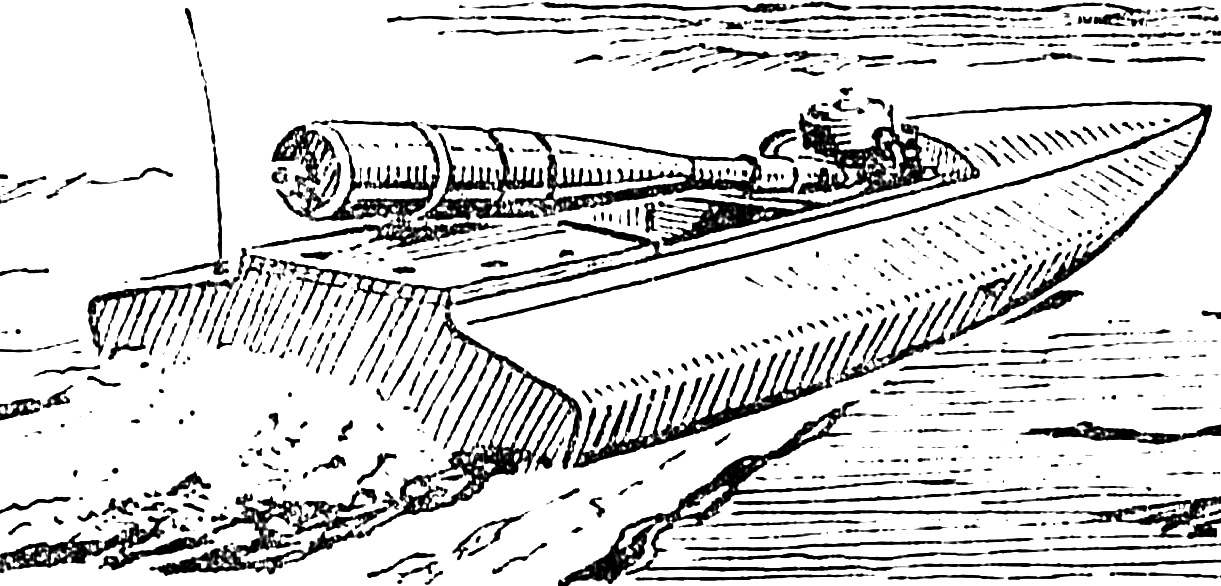

Today we offer RC modelers a high-speed hydroplane races for long, designed and built by famous Hungarian athlete Istvan of Salim. “Salamander” — the so-called new microtiter — has a number of features. For example, in order to model flooding and to reduce noise emanating from a thin shell of case-“cavity”, messageone section partially filled with polyurethane foam. The vibration transmitted to the housing of the engine, is reduced not only due to the installation of all engine mounts, rubber gaskets-absorbers, but also applying the printed parts of the base of the motor. The fact that the conventional PCB has unlike fiberglass the best shock-absorbing properties. The noise of the exhaust is possible to reduce cooling of the exhaust pipe part of the water coming out after the heat extraction from the engine. Ejection of the cooling water of the engine and the exhaust pipe is carried out on individual tubes. This simplifies the adjustment of fluid flow through two independent channels.

These techniques provide significant reduction of noise of the whole model, with no throttling of the exhaust, reducing engine power. The need for noise abatement actions is obvious — as in all other ship classes, in the class FSR the allowable level of noise is limited to a rather low value of 80 dB. To achieve such characteristics, serving as a kind of “pass” for the area (with increasing noise, the model is immediately removed from the race, the control of noise is carried out for all scoring heats), is not so simple. Literally, every node in speed microcamera have to decide, given the “vociferous” modern high-speed uprated engines.