Not often, but sometimes: spin rubber motor on the model, and suddenly it breaks. And it brings a lot of trouble. However, more recently, the fuselage of this “accident” is not suffering — its the working part on rezinomotornaya model aircraft are now in the form of a solid tube made of aluminum or fiberglass. But the propeller is still defenseless. Devices used to protect it from breakage, disks or rectangular plates of sheet aluminum not withstand strong impact. In addition, they are massive and awkward to use.

Not often, but sometimes: spin rubber motor on the model, and suddenly it breaks. And it brings a lot of trouble. However, more recently, the fuselage of this “accident” is not suffering — its the working part on rezinomotornaya model aircraft are now in the form of a solid tube made of aluminum or fiberglass. But the propeller is still defenseless. Devices used to protect it from breakage, disks or rectangular plates of sheet aluminum not withstand strong impact. In addition, they are massive and awkward to use.

But to tighten the rubber motor without screw. You will need only to reconstruct si” louuu head model.

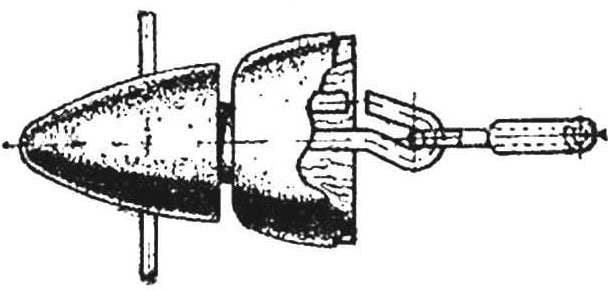

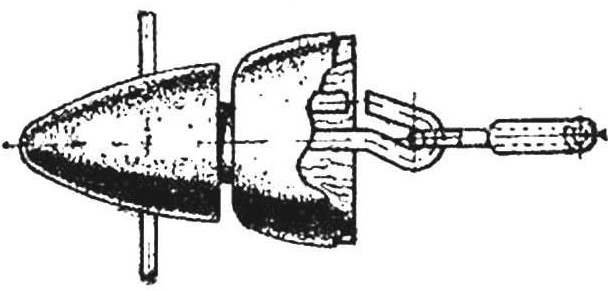

Figure 1 shows the power head before and after the reconstruction, which consists in reducing the size of the hook for the rubber motor (A) and the introduction of new items — “eight” (B). The sizes of these parts are for the fuselage Ø 33 mm. this eliminates the need in the front loop under the hook of the drill. And one more detail it is necessary to make: supporting tube (Fig. 2).

Fig. 1. Reconstruction of the power head:

1 — trouble, 2 — after the alteration; And — the hook (wire OVS), B — “eight” (wire OVS).

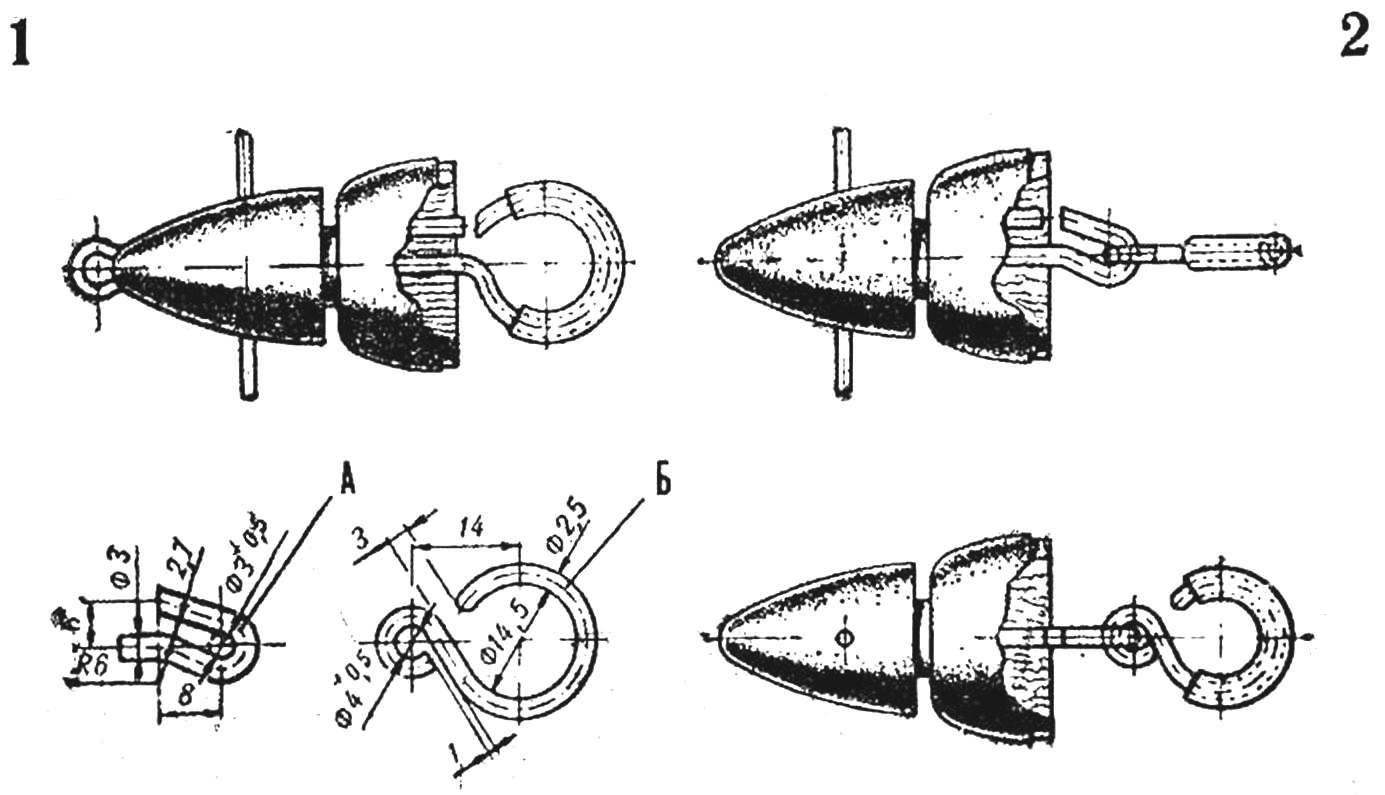

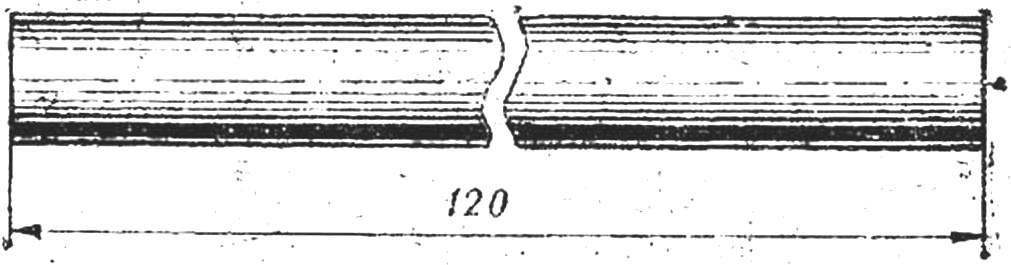

Fig. 2. Auxiliary pipe Ø 9 mm.

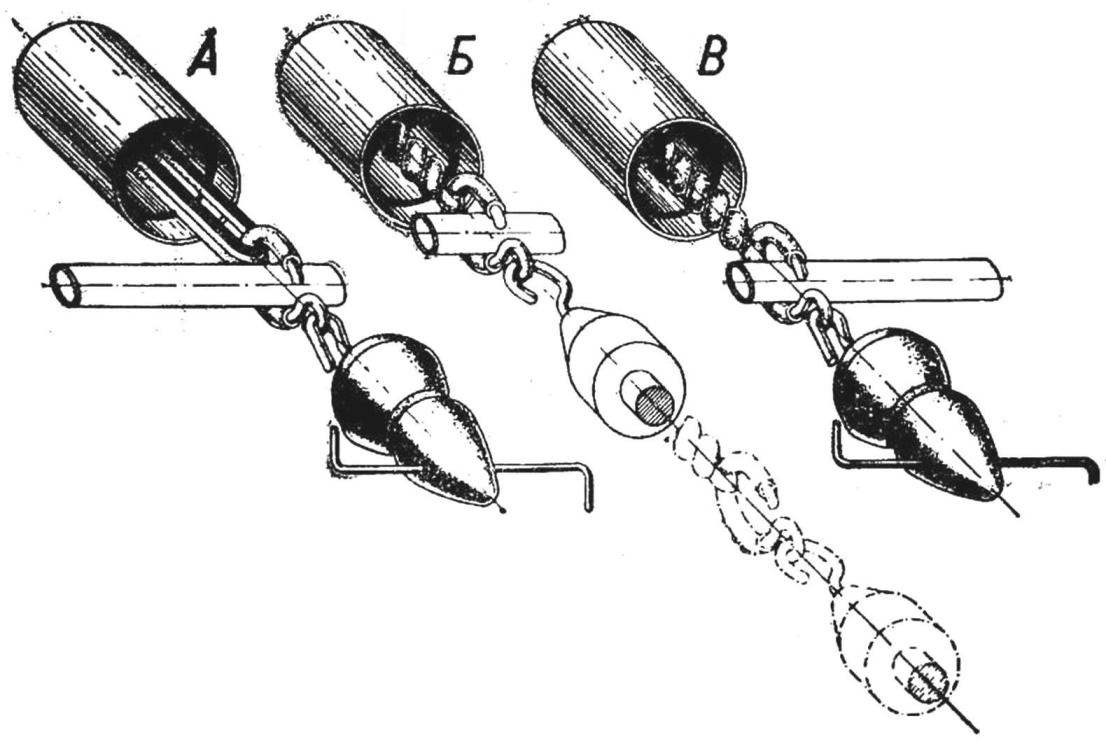

Fig. 3. Tightening the rubber motor without screw:

A recording of “eight” of the auxiliary pipe, B — Union of a drill to tighten the rubber motor, — install the power head.

The order of tightening the screws without the rubber motor is that the fuselage is removed from the power head. Tube inserted into the large ring of the group and is held securely with the left hand, and right at this time removes the power head screw (Fig. FOR). Then into the small ring of the group is put the hook on the drill remove the auxiliary tube and install the rubber motor (Fig. BV). The last stage in the group again is inserted into the auxiliary tube, the drill is removed and put back on hook the power head screw (Fig. THIS). It remains to remove the auxiliary tube and insert into the fuselage of the power head.

Reconstructed power head offers, in addition to said two essential advantages: “eight” in combination with the small hook serves as a ball joint and minimizes the runout of the rubber motor during the unwinding. Reduced bending moment acting on the screw shaft, thus reducing the fatigue loads and radial forces acting on the ball bearings.