For the manufacture of parts for models of artillery and torpedo armament of the marine models usually spent a lot of time, it is not always possible to achieve full similarity. Some of the devices and techniques that facilitate the machining of parts and reduces their production.

For the manufacture of parts for models of artillery and torpedo armament of the marine models usually spent a lot of time, it is not always possible to achieve full similarity. Some of the devices and techniques that facilitate the machining of parts and reduces their production.

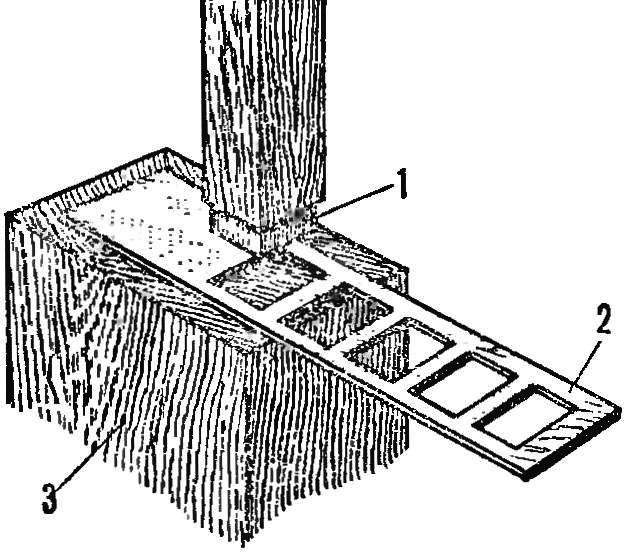

As billets artillery towers serve as pieces of wood, vystragivanie width and height under a square. The easiest way to crop the bar on the mitre box — so carpenters call a wooden U-shaped drawer with slots (Fig. 1). You must make sure that the saw in the slot was moving without deviation to the side, forming a straight cut. If the fixture to set the focus (Fig. 2), the workpiece to obtain the desired length and without markup. Important detail: to avoid damage to the future of the tower, it should be treated according to the templates in a wooden vise.

Clean and smooth the surface of the part, eliminating the need for additional finishing, it is possible to obtain when processing it on a grinding wheel. The circle consists of a rotary table (two-to three-millimeter steel) and electric motor with detachable sanding discs.

Sampling holes and drill holes under the barrels of the guns cause more problems. Modelers should take into account that these operations must only be performed in the raw configuration of the workpiece.

Artillery tower of the main and medium caliber naval model can be made of thin sheet metal. It is first of solid wood, plastic or aluminium mandrel is in the form of a tower. She removed the paper template scan, in which taking into account the allowances are cut and milled in it the breach (this can be done in batch). After that, sweep bends, extracts and soldered on the mandrel.

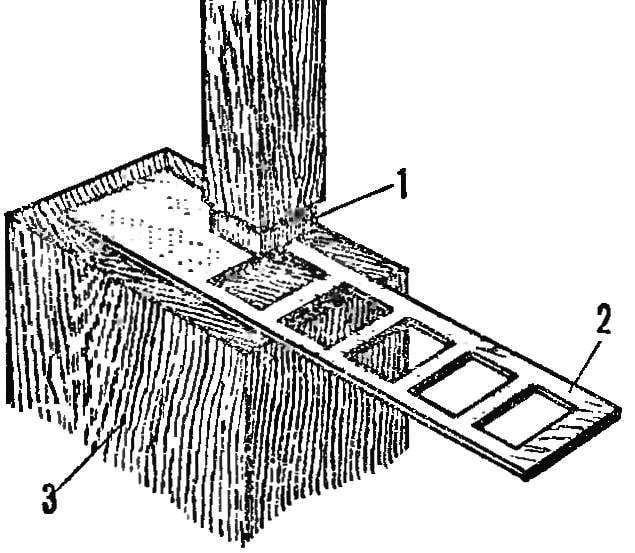

Small details if they need a lot, the easiest way manufacturing method of perforation (Fig. 3). This sheet three-six-millimeter steel cut the exact contour of the workpiece, which is then fastened with screws or soldered to the shank length of 100-120 mm. Then at the end of the smooth hard wood, put a sheet of tin and with a metal perforation punch it on the entire area of the end face. The upper part of the end cut and break off. Fallen from the tree at places or had the details align on the metal tile.

Caps of various shapes made of celluloid or organic glass (plexiglass) in a wooden mold (Fig. 4). It consists of a wooden punch and a simple matrix made out of plywood with a thickness of 4-6 mm. at the Beginning of the workpiece softened: celluloid — in boiling water, organic glass in the engine oil, heated to 110-130°. The thinner the material, the better it is in the sky.

Small parts of complex shape, for example, breech multi-barrel artillery (Fig. 5), are cast out of lead in aluminum forms.

For assembling and filing of pipes torpedo tubes, you can use a simple jig (Fig. 6). Soldered in this way the elements will be located without bias in the same plane. Flaring of pipes produced by a special device (Fig. 7): in the steel bar is drilled and then sawn a hole of the desired shape. To prevent damage to the workpiece in a vise, use a lining of soft metal like aluminum or red copper. Then light hammer blows on the groove tube resultshowever.

The rifled artillery platforms and sites under the torpedo tubes it is convenient to do on the old “personal” file light hammer blows on the workpiece.

In cases where the Modeler doesn’t need a lot of parts for gun mounts and torpedo tubes, they can cut a piece of celluloid, glass or ebonite, and then stick emalita or glue BF-2 on pre-primed surfaces.

A. KOCHERGIN, A. EFIMOV