To make such a starter is not too difficult. You’ll need gear with outside Ø 16-20 mm. the tooth Module can be anything, however it is not necessary to use gears with too small a tooth — when the misalignment of the rails, which is inevitable at the start, they will quickly work together.

In gear it is necessary to cut a tapered hole corresponding to the landing cone of the motor shaft, and to pierce its ends so that the items formed two lugs. On one side of the screw — cut triangular grooves: a notch.

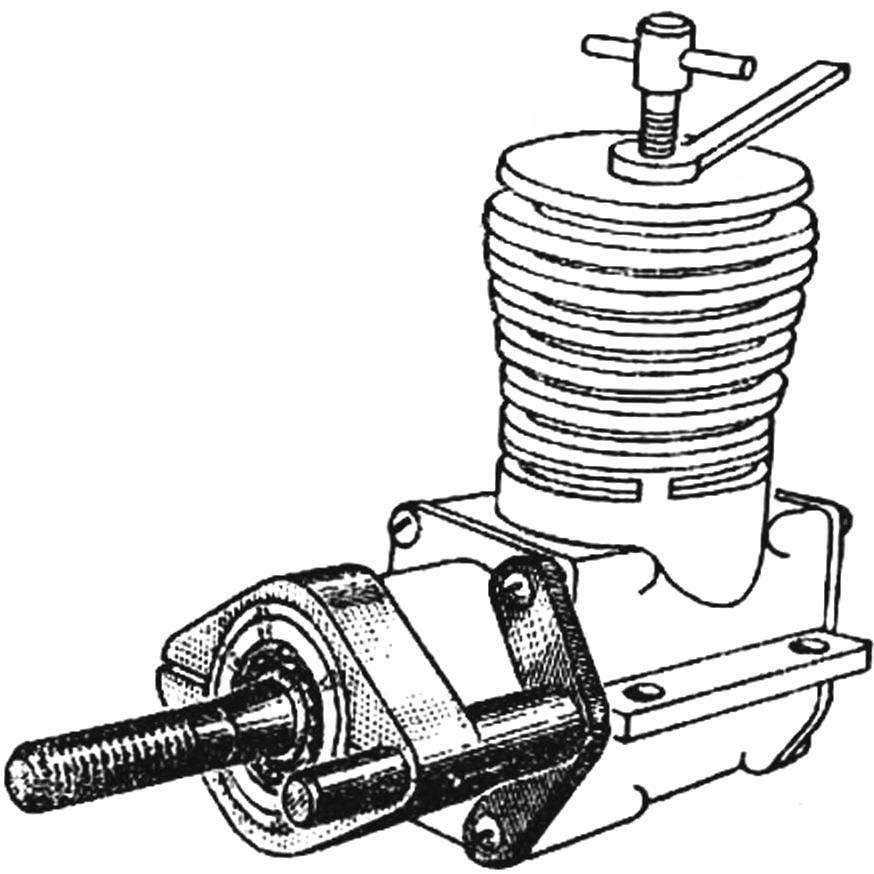

Fig. 1. Starter for micro-motors and details:

1 — nut of fastening screw, 2 — washer, 3 air piit, 4 — restrictive washer, 5 — gear, 6 — shaft, 7 — the case latch, 8 — spring.

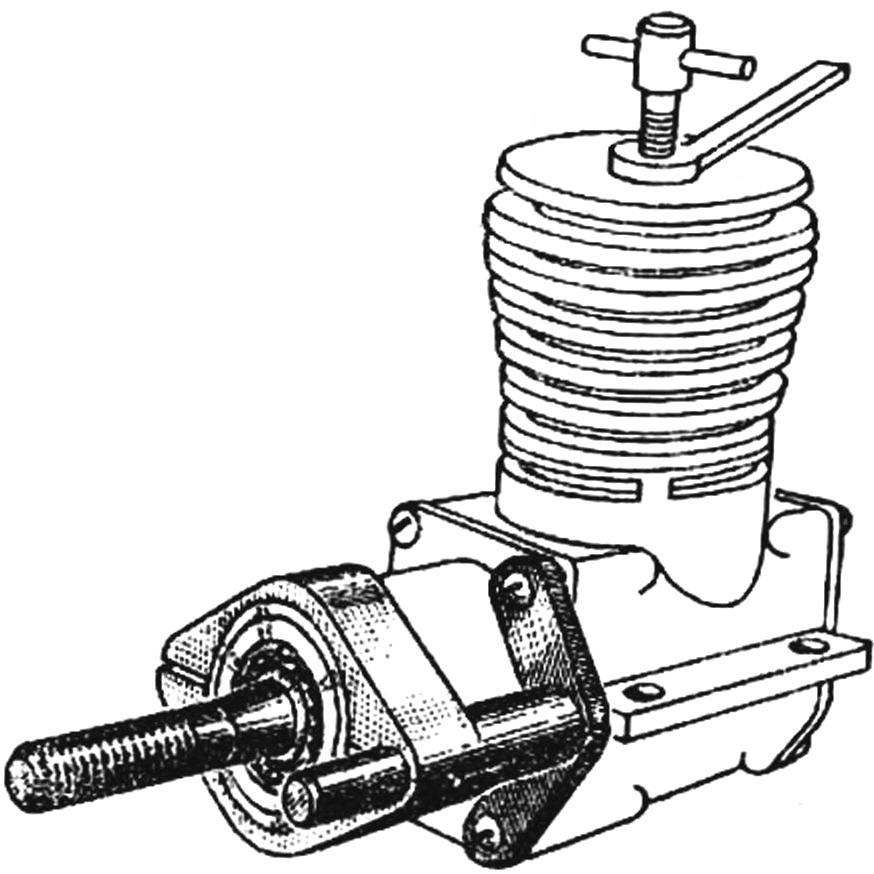

Fig. 2. Install the latches on the engine.

Fig. 3. Gear rack.

Support of the rack when charging the Microdrive is a special latch — stock. The body of this node is machined from duralumin, the stock represents a segment of a steel rod Ø 6 mm. In operating position it is held by a helical spring wound from wire Ø0,25 mm.

It remains to manufacture the toothed rail. The length of its working part should be about 500 mm, and the thickness and height to match the gear width and the distance from the stem to the circumference of the depressions of the gear. The modules of the teeth of the rack and pinion must be identical.

Arm slats cut from two textolite plates to fit on the hand and propisyvaetsya the groove under the rail. Fastening the latter to the handle with M4 screws.

After mutual adjustment of parts, you are ready to start the engine. First of all, take stock, put the rack on the gear and lock it by the latch. Holding the model with the left hand, right hand pull sharply on the rail itself — the engine starts.

Recommend to read

ANCHOR — FROM ANCIENT TIMES TO THE PRESENT DAY

ANCHOR — FROM ANCIENT TIMES TO THE PRESENT DAY

Oddly enough, but we tend to think of Ancient Rus agrarian power, traded mainly salt, hemp, wax, fur goods, linen. Meanwhile our ancestors were taken abroad and iron, and iron, famous... JAGUAR R-COUPE

JAGUAR R-COUPE

The basis of the most famous British car company Jaguar Cars was firm SS Car Company, which in 1945 had to change its name — becauseone SS at that time, no one called benevolent...

To run the motor manually? And fingers will discourage, and not always with a half-turn wind up cranky diesels. And the competition time limit to run very hard. Did not fit in the allotted minute — and-goal instead of numbers in judicial protocols appear null.

To run the motor manually? And fingers will discourage, and not always with a half-turn wind up cranky diesels. And the competition time limit to run very hard. Did not fit in the allotted minute — and-goal instead of numbers in judicial protocols appear null.