Assemble the center section on a flat Board stocks, which put the drawing and the sheet of transparent Mylar or plastic film. The place of gluing of the ribs to the edges of the reinforcing gussets in the form of rectangular triangles with legs of 3 and 6 mm.

Assemble the model using PVA glue. In observance of the precautions you can use canoak, filatovym with glue such as “super moment” or similar foreign production.

End corner of the wing, stabilizer and fin are glued together of two strips of veneer of pine or basswood with a thickness of 0.7 mm on a mandrel of appropriate shape. For the veneer strips with a width of 10 mm, soaked in hot water, then secure them in two layers to the side surfaces of the mandrels with gluing layers in between with white glue. After complete drying of the workpiece is sawed lengthwise into strips with a width of 1.5 mm.

The ends of the center section and the wingtips carefully adjust to each other, providing the necessary “V” “ears”. The place of gluing the winglets reinforce the gusset.

In the manufacture of the stabilizer and glue the first frame of edges and endings, and connect the “on condition”. The length of the bevel of not less than 6mm. Then glued the ribs and reinforcing gusset plate.

The lower ends of the struts on the wing length of approximately 10 mm have a cross section with a diameter of 1.5 mm. They are glued to the edges of the wing and reinforce, connecting with the Central rib gussets with sides 10×10 mm, and by the edges of the four struts (two on the front and back).

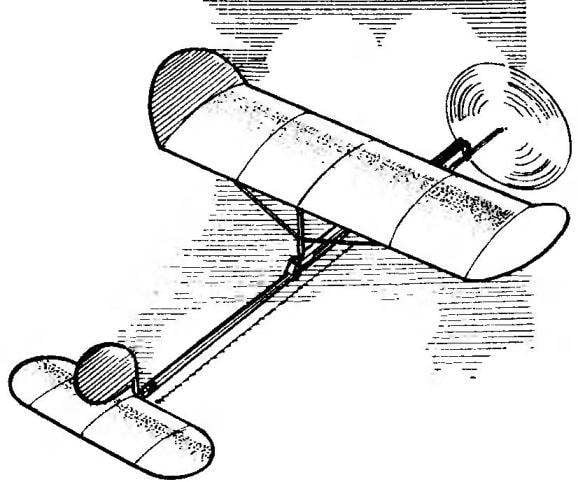

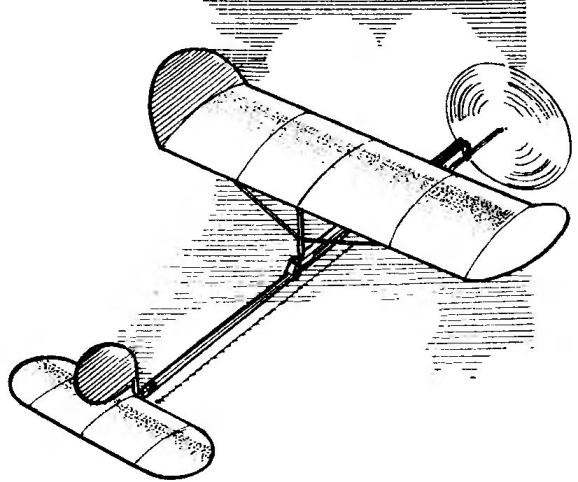

Room model airplane:

1 — screw, air (balsa); 2 — bead (PTFE); 3 — the bearing (aluminum, sheet s1,5 18×5); 4 — the screw shaft (the elastic wire Ø1,2); 5 — rubber motor (thread 3×1,2); 6 — pylon (Linden); 7 — solitaire (balsa, s1,2, 10×10); 8 — winding (rubber, 1×1); 9 — fuselage (straw, 06); 10 — bracket keel (balsa, 12x9x5); 11 — solitaire (balsa, s1,2, 6×3); 12 Kil (Linden, rake 1,5×1,5); 13 —beam tail (lime, rake 3×2); 14 — edge of the wing and stabilizer (lime, pine, 1,5×1,5); 15 — a lining (thin polyester, capacitor paper); 16 — wingtips and stabilizer (lime, pine tree, rack 1,5×1,5); І7 — rib (Linden, pine, RecA 1,5×1,5); 18 — the plug (balsa, L20); 19 insert (balsa); 20 — brace (lime, rake 1.5 x 1.5); 21 — front (pine tree, rack 1,5×15).

The pylon is cut from lime bar 145×6,5×5,5 mm. Its terminal region from the bottom to the length of about 25 mm shape of the concave cylindrical surface with a diameter of 6-7 mm. the Central part of the bottom is extremely easy, and the top scroogled. In pole drilled two through holes for tight fit wing struts.

The rudder is rounded. The only place gluing reinforce the gusset plate. The length of the shank to install in the bracket is 20 mm, 15 mm from them (from the end) is a round section with a diameter of 1.5 mm.

The fuselage consists of two parts — the powerplant and tail. Power is made from two straws with a diameter of 6 mm, connecting them together and glued a cylindrical insert of balsa with a length of 10 mm. At the free ends of straws glued the balsa plugs with a length of 20 mm. At the rear of the plug the drill hole depth of 10 mm, which is glued to the tail boom of lime. On the front bottom fell polivaut a flatted length 18 and a width of not less than 2.5 mm for the installation of P-obratnogo shaft bearing propeller. The bearing is bent from a strip of aluminum with a width of 5 mm and a thickness of 1,5 mm. Length of 18 mm. Its bearing and rear hook (hard wire 0.8 mm diameter) attached to the fuselage with thread and glue.

The tail boom close to the end of the straw tubes are glued billet bracket keel with dimensions 12x9x5 mm. direction of the layers of wood along the longest side. The final shape gives it after the glue dries and the hole for the installation of the keel gently adjust to ensure a tight fit to the shank.

Glued to the tail boom and stabilizer. Splices edges with the beam reinforce the corners of the balsa or basswood glued to the edges of the stabilizer from the bottom.

The propeller is made from a dense block of balsa. The blades are convex-concave profile having a maximum thickness of 1.5 mm. Other (less time consuming) option — the screw with the hub size 10x8x6 mm and glued to her blades from basswood 100x30x1,2 mm, made on the “bottle” technology. A cylindrical mandrel in this case with a diameter of about 200 mm, and the angle of the work piece the blade with the generatrix of the cylinder is 20°. Of course, the advantage remains with the screw, made the templates from the bar. Ready screw carefully balance.

The propeller shaft is of stiff wire with a diameter of 1.2 mm To reduce friction during rotation of the shaft put a spherical “bead” or a set of washers, preferably made of PTFE. The propeller is fixed due to the bending of the front end of the shaft.

Wing, stabilizer and fin are covered Mylar film 10 µm thick or a thin condenser paper. In both cases, for attaching trim to use glue “Moment”, diluted with solvent 647, which is added to the glue in small doses with careful stirring. The mixture is applied on the upper surface edges of the winglets and ribs in two layers. The second layer is coated after drying of the first. It’s also fully dried. The wing, stabilizer and fin one-sided. It is glued to the frame spout hot iron or the tip of the iron.

The wing is covered in two stages: first the center section, then the “ears”. After gluing the sheathing in the area of the first end of the ribs is applied to the adhesive strip width of 5 mm, it is attached trim the “ears”. Blanks for covering the cut with an allowance of 6-10 mm on a side. After the glue dries allowances, cut it with a razor blade or a co-skrivaut. In the case of Mylar film lining you can gently pull the iron. When using a condenser paper to moisten the covering with water is not recommended, as this may cause excessive tension of the plating and deformation of the structure.

Wing stand installed in the holes of the pylon, the end portions which secure them to the fuselage with rubber thread. In the hole of the bracket, inserting the shank of the keel. At the end check the correctness of the model geometry and eliminate the distortions.

The rubber motor is made from two strands of quality rubber with a cross-section 3×1 mm. This allows you to tighten it to 400 rpm. The entire flight takes place with the engine running.

The model is adjusted so that she was flying right-hand turn. First, it set up for straight flight, moving the keel in one direction or another. A smooth climb-out work to change the alignment, moving the pylon of the wing along the fuselage, as well as increasing or decreasing the mounting angle of the wing due to the selection of the lengths of its struts. The rubber motor at the same plant 150-200 rpm.

Then the keel deviate to the right (3-5 mm in top view at the rear end edge of the keel from the position of the straight flight) and check the response of the model. If re-cinematica continues to climb, but the bend is too small, the keel reject even more. When entering the model into a downward spiral wing move forward. If that’s not enough, then increase the mounting angle of the wing. The lack of stability flight you can recommend adjustment not only to the deviation of the keel, but the warp stabilizer. Properly adjusted, the model gains altitude circles with a diameter of about 6 m and is in the air for about a minute. After the final adjustment can be glued gusset plate, fixing stand wing on the pylon.

Some recommendations for those interested in “heavy” room models. All the details of the structure, made from balsa, including the propeller, can be made of light lime. The fuselage can be made from balsa or light pine rails constant rectangular 6×4 mm to the rear of the hook and gently rolling cross-section of 1,5×1,5 mm at the end. In this case, the pylon has a flat bottom surface. If the technology of manufacturing of curved elements seem too time consuming, “ears” of the wing you can make a trapezoid by typing them in three strips. The stabilizer and fin may be rectangular. Flying qualities of the model almost does not change.

This development is the result of the search for new themes for educational programs aeromodelling circle (the head of which are working since 1980) designed to acquaint students with the maximum number of different models. With a “heavy” isinomuotume at the beginning of each school year, I am graphic propaganda flights. Launch models are mostly in school gyms, it gives an opportunity to establish and strengthen ties and supplementary education.

A logical extension of such models may be a class of miniature rezinomotornaya copies, has long cultivated in Czechoslovakia and known as “twenty” (1:20 scale). Competitions with models such classes can be all-weather and all-season.

Yuri MOISEEV,

methodologist, teacher syut, Zheleznodorozhny, Moscow region.

Recommend to read ALL ABOUT THE MAP "you Wrote Pankov Alexey Illarionovich, the leader of the group for karting at the House of pioneers city of Genichesk of the Kherson area. I appeal to you to help me and my kids in the... HACKSAW-“THE DENTIST” If the saw teeth from long term use it had lost its sharpness and shape, it can be corrected with a file of triangular cross-section or a suitable needle file. But you first need a...  For the last four years on the initiative of the heads of model aircraft clubs in the town of Zheleznodorozhny in the Moscow region competitions school students in the new class of resinator indoors. If you compare these models with others, participating in competitions, for example, a glider and a helicopter “Fly”, the proposed resonatory more complex. Therefore, it can be recommended for the manufacture of the guys visiting the club for the second year.

For the last four years on the initiative of the heads of model aircraft clubs in the town of Zheleznodorozhny in the Moscow region competitions school students in the new class of resinator indoors. If you compare these models with others, participating in competitions, for example, a glider and a helicopter “Fly”, the proposed resonatory more complex. Therefore, it can be recommended for the manufacture of the guys visiting the club for the second year.