models of gliders classes A1 and A2 must satisfy three requirements — stiffness, strength and low weight. The best results are obtained by the use of tapered thin-walled fiberglass or balsa tubes. But the technology of manufacturing these beams is difficult. Our proposed design is much simpler, the material for it is available to everyone. Despite its simplicity, such a beam is well proven in operation.

models of gliders classes A1 and A2 must satisfy three requirements — stiffness, strength and low weight. The best results are obtained by the use of tapered thin-walled fiberglass or balsa tubes. But the technology of manufacturing these beams is difficult. Our proposed design is much simpler, the material for it is available to everyone. Despite its simplicity, such a beam is well proven in operation.

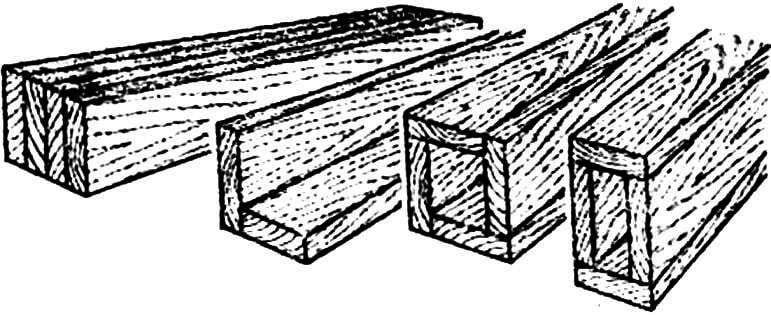

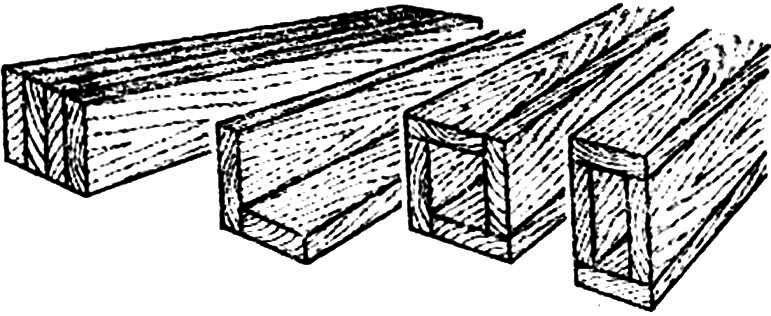

For the tail of the glider class A1 will need four smooth without ROE pine rails with a section of 2X8 mm, for models of class A2 — 2X10 mm. Cut down the length to size and glue on the “spots” into a bundle. The handle bar plane to a height of 7 mm (9 mm for A2) in front and 3 mm (4 mm) at the rear. Then using a thin knife, disassemble the pack and separate strips prostrate — front, they should have a section 2X7 mm (2X9 mm) back — 0. 8X3 mm (1X4 mm). Glue the spars received in pairs so as to form two l-obrany profile. When the glue is dry, completely assemble the beam. Very carefully the quality of the glue joints (epoxy better not to apply it too heavy). The joints must be pre-primed with glue.

Finished lacquered beam A1 glider has a weight of 9 to 11 g glider A2 — 15 to 20 g.